Laminated Board

-

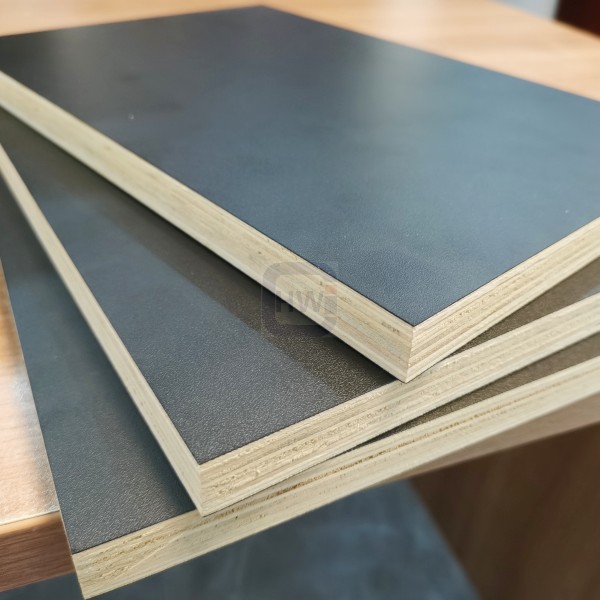

18MM Black HPL Faced Plywood

- 18MM Black HPL Faced Plywood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Face/Back: HPL/custom

- Core: Poplar/Eucalyptus/Combi

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:3–18mm/custom

- Glue:E0/E1/E2/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 520-700KGS/CBM

- Moisture Content: <12%

-

Black Matt HPL Plywood – Fireproof Plywood

HPL means “High-Pressure Laminates”. HPL is a kind of engineered plastic laminate. After the plywood has been produced, HPL is covered onto the face/back of the plywood under high pressure. That’s what people call “HPL Plywood”.

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB, EPA, JAS, ISO

- Face/Back: HPL/custom

- Core: Poplar/Eucalyptus/Combi

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:3–18mm/custom

- Glue:E0/E1/E2/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 520-700KGS/CBM

- Moisture Content: <12%

-

CHANGYU 3-18MMx4x8 HPL Faced Coated Plywood for Furniture

· HPL Faced Coated Plywood

Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB, EPA, JAS, ISO

· Face/Back: HPL/custom

· Core: Poplar/Eucalyptus/Combi

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–18mm/custom

· Glue:E0/E1/E2/Custom

-

Engineer Veneer Fancy Plywood – Decorative Veneer Plywood – UV Coating Fancy Plywood

Engineer Veneer Fancy Plywood – Decorative Veneer Plywood

Fancy plywood, also called decorative plywood, is usually veneered with good-looking hardwood veneers, such as red oak, ash, white oak, birch, maple, teak, sapele, cherry, beech, walnut and so on.

Red oak ( grade: AAA/AAA, BB/BB, A/B, B/C, c/c) fancy plywood, natural ash, red beech, white oak (Q/C), red beech, bubinga, sapele (C/C), natural teak(C/C), ect.

Red oak (c/c) fancy plywood, natural ash, red beech, white oak (Q/C), red beech, bubinga, sapele (C/C), natural teak(C/C), ect.

-

Formica Plastic Laminate Sheets

- HPL Plywood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Face/Back: HPL/custom

- Core: Poplar/Eucalyptus/Combi

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:3–18mm/custom

- Glue:E0/E1/E2/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 520-700KGS/CBM

- Moisture Content: <12%

-

Glossy UV Birch Plywood

Glossy UV plywood finish featuring a clear, durable top coating to add toughness, resisting to scrapes and chip. UV coating is basically a compound that is applied to wet wood and then instantly dried by ultraviolet light. Several different types of compounds are used to coat wood.

- UV Coated Plywood

- Loading Quantity: 20’GP-8pallets/20CBM, 40’HQ-18pallets/40CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Face/Back: UV Lacquer

- Core: Birch /Customs

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:5–30mm/custom

- Glue:Phenolic/E0/E1/E2/Custom

-

HPL Birch Plywood For Sale

HPL Birch Plywood

HPL means “High-Pressure Laminates”. HPL is a kind of engineered plastic laminate. After the plywood has been produced, HPL is covered onto the face/back of the plywood under high pressure. That’s what people call “HPL Plywood”.

Furniture HPL birch plywood, also known as a refractory sheet, is known as high-temperature laminated cardboard with paper impregnated with heat-curing resin. The British acronym (HPL) is a fire-resistant building material for surface decoration. It has rich surface color, texture, and special physical properties. Fireproof panels are widely used in interior decoration, furniture, kitchen cabinets, laboratory bench, exterior walls, and other fields.

-

HW 4×8 E0/E1 fancy veneer coated Plywood

· Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

Surface: red oak, ash, white oak, birch, maple, teak, sapele , cherry, beech, walnut and so on

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–30mm/custom

· Glue:E0/E1/E2/Custom

-

HW 4x8x18MM White HPL Plywood

- White HPL Plywood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Face/Back: HPL/custom

- Core: Poplar/Eucalyptus/Combi

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:3–18mm/custom

- Glue:E0/E1/E2/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 520-700KGS/CBM

- Moisture Content: <12%

-

HW UV Coated Pine Plywood for Furniture Making

· UV Coated Plywood

Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

· Face/Back: UV Lacquer

· Core: Poplar/Eucalyptus/Combi

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:5–30mm/custom

· Glue:E0/E1/E2/Custom

-

HW fancy veneer-coated Plywood

· Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB, EPA, JAS, ISO

Surface: red oak, ash, white oak, birch, maple, teak, sapele , cherry, beech, walnut, and so on

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–30mm/custom

· Glue:E0/E1/E2/Custom

-

HW Furniture Grade Melamine Faced Plywood

· Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

· Face/Back: Melamine Paper/custom

· Core: Poplar/Eucalyptus/Combi

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–30mm/custom

· Glue:E0/E1/E2/Custom

Laminated Board Introduction

A laminated board, also known as laminated wood, is a type of engineered wood that is made by layering thin sheets of wood veneer or other materials together using adhesive. The resulting board is stronger and more durable than natural wood and can be used for a wide range of applications. Including furniture, cabinetry, flooring, and decorative panels. The process of making this type of board involves bonding layers of wood veneer or other materials. Such as particleboard or MDF (medium-density fiberboard), together with the help of an adhesive. The adhesive used can be made from a variety of materials. Such as phenol-formaldehyde, urea formaldehyde, or melamine. The laminated board comes in a variety of thicknesses, sizes, and grades, and can be made from different types of wood. Such as pine, birch, or oak. It is also available in different finishes. Such as smooth, textured, or glossy. One of the main benefits of this board is its strength and durability, which make it ideal for use in high-traffic areas or where moisture and humidity are a concern. It is also resistant to warping, cracking, and splitting. Which makes it a popular choice for outdoor furniture and construction applications. Overall, the board is a versatile and reliable material that offers many benefits over natural wood and is widely used in a variety of industries and applications.Laminated Board Feature

- Strength and Durability: It is stronger and more durable than natural wood, making it ideal for use in high-traffic areas and where moisture or humidity is concerned. It is also resistant to warping, cracking, and splitting. Which makes it a popular choice for outdoor furniture and construction applications.

- Versatility: This board comes in a variety of thicknesses, sizes, and grades, and can be made from different types of wood or other materials. It is also available in different finishes. Such as smooth, textured, or glossy.

- Consistency: Because the laminated board is manufactured. It has a consistent quality and appearance. Making it easier to work with and ensuring that the final product looks and performs as intended.

- Cost-Effective: The board is typically less expensive than solid wood. Making it a cost-effective alternative for many applications.

- Sustainability: This type of board is made from renewable materials and can be recycled or reused. making it a sustainable choice for environmentally conscious consumers.