HW Furniture Grade Melamine Faced Plywood

HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood is a type of plywood that is designed specifically for furniture-making purposes. It is made from high-quality hardwood veneers that are glued together with a waterproof adhesive and then coated with a layer of melamine on one or both sides.

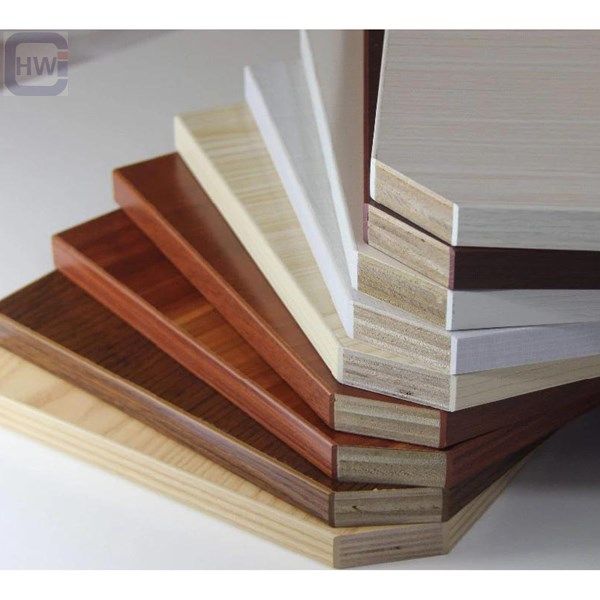

The melamine coating gives the plywood an attractive and durable finish that is resistant to scratches, stains, and moisture. It comes in a variety of colors and patterns, making it a popular choice for furniture, cabinets, and other interior applications.

HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood is available in a range of thicknesses from 3mm to 30mm, and in standard sheet sizes of 4×8 feet. This makes it easy to find the right size and thickness for your specific furniture-making project.

Product Details

Quick read of melamine plywood

Melamine plywood is the ideal material for the furniture, interior decoration ,floor and so on . It has the characteristics of pollution-free,scratch resistant ,heat resistant and moisture-proof ,while retaining the original wood structure.Its features provide high visual quality with smooth and superior surfaces that are ready for use.The color of melamine can be solid color such as white, black,gray.

Wood grain color such as oak ,sapele,teak ,cherry . cloth grain and marble grain. The core we choose from high quality full pieces poplar ,birch or Eucalyptus veneer to make sure the plywood with uniform thickness, super flat surface and high bending strength . Melamine paper also can apply on MDF ,chipboard and blockboard.

HW Furniture Grade Melamine Faced Plywood Feature

1. High-Quality Hardwood Veneers: The plywood is made from high-quality hardwood veneers that are carefully selected for their strength, stability, and uniformity. This ensures that the plywood is strong and durable, with a consistent appearance.

2. Water-Resistant Adhesive: The hardwood veneers are bonded together with a water-resistant adhesive that makes the plywood resistant to moisture and humidity. This makes it ideal for use in areas that are prone to moisture, such as bathrooms or kitchens.

3. Melamine Coating: The plywood is coated with a layer of melamine on one or both sides, which gives it an attractive and durable finish. The melamine coating is available in a variety of colors and patterns, making it a popular choice for furniture-making applications.

4. Easy to Clean: The melamine coating makes the plywood easy to clean and maintain. It can be wiped down with a damp cloth to remove dirt and stains, and it is resistant to scratches and other types of damage.

5. Versatile: HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood can be used in a wide range of furniture-making applications, including cabinets, bookshelves, desks, and tables. Its versatility makes it a popular choice for both commercial and residential applications.

6. Cost-Effective: Compared to solid wood or other high-end materials, HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood is a cost-effective option that offers excellent durability and aesthetics. This makes it a popular choice for budget-conscious consumers who still want high-quality furniture.

Basic Parameters

| Product Name | HW Melamine Paper Faced Plywood/Board | ||

| Size | 1220x2440mm/1250x2500mm/ or as clients requirement | ||

| Thickness | 3-30mm | ||

| Thickness Tolerance | +/-0.2mm (thickness<6mm), +/-0.3~0.5mm (thickness≥6mm) | ||

| Face/Back | Melamine Paper 180-220g/m2 and color as clients requirement | ||

| Core | Plywood, Block Board, MDF, PB Board | ||

| Glue | E0, E1, E2, MR, Melamine or WBP | ||

| Hot Press | Direct and Composite faced | ||

| Density | 520~700kg/m3 | ||

| Technical Parameters | Moisture Content | <12% | |

| Water Absorption | ≤10% | ||

| Modulus of Elasticity | ≥5000Mpa | ||

| Static Bending Strength | ≥30Mpa | ||

| Surface Bonding Strength | ≥1.60Mpa | ||

| Internal Bonding Strength | ≥0.90Mpa | ||

| Screw Holding Ability | Face | ≥1900N | |

| Edge | ≥1200N | ||

| Usage & Performance | Plywood is widely used for Automotive Interior ,furniture, decoration, construction and packing. With good properties, such as, easy fabricability, high bending strength, strong screw holding ability, heat resistant, anti-static, long-lasting and no seasonal effect. | ||

| MOQ | 1×20’FCL | ||

| Supply Ability | 5000cbm/month | ||

| Payment Terms | T/T or L/C at sight | ||

| Delivery Time | Within 20 days after receiving deposit or original L/C at sight | ||

| Certification | CE, FSC, EUTR, CARB,EPA, JAS, ISO | ||

Technical Parameters

| Moisture Content | 8%~14% | |

| Modulus of Elasticity | ≥2500Mpa | |

| Static Bending Strength | ≥22Mpa | |

| Surface Bonding Strength | ≥1.20 Mpa | |

| Internal Bonding Strength | ≥0.55 Mpa | |

| Screw Holding Ability | Face | ≥1300N |

| Edge | ≥800N | |

Surface Species

Delivery Instructions

| Packing | Standard Export Pallet Packing | Inner Packing | Pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | Pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/50cbm | |||

Packaging and Containerization

Application

Commercial Plywood for Furniture, counter tops, laminations, kitchens, and other interior work, as well as for other usages.

FAQ

Q: What is HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood?

A: HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood is a type of plywood that is designed specifically for furniture-making purposes. It is made from high-quality hardwood veneers that are glued together with a waterproof adhesive and then coated with a layer of melamine on one or both sides.

Q: What are the dimensions of HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood?

A: HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood comes in a range of thicknesses from 3mm to 30mm, and in standard sheet sizes of 4×8 feet.

Q: What are some applications of HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood?

A: HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood can be used in a wide range of furniture-making applications, including cabinets, bookshelves, desks, and tables.

Q: Is HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood water-resistant?

A: Yes, HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood is water-resistant due to the use of a water-resistant adhesive during the manufacturing process.

Q: How is HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood different from regular plywood?

A: HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood is specifically designed for furniture-making applications and has a layer of melamine on one or both sides, which provides an attractive and durable finish. Regular plywood may not have a melamine coating and may not be specifically designed for furniture-making applications.

Q: Is HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood more expensive than regular plywood?

A: HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood may be slightly more expensive than regular plywood due to its higher quality, water-resistant adhesive, and melamine coating. However, it is still a cost-effective option compared to solid wood or other high-end materials.

Q: Can HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood be painted or stained?

A: Yes, HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood can be painted or stained like regular plywood. However, it already has an attractive finish due to the melamine coating, so painting or staining may not be necessary.

Q: Is HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood environmentally friendly?

A: HW 3-30MMx4x8 Furniture Grade Melamine Faced Plywood is made from sustainably sourced hardwood veneers and uses a water-resistant adhesive that does not contain formaldehyde, making it a more environmentally friendly option than some other types of plywood.