Formwork Plywood

-

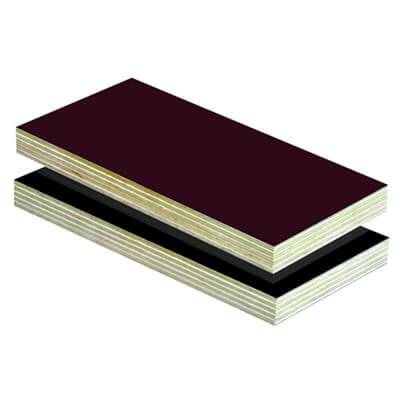

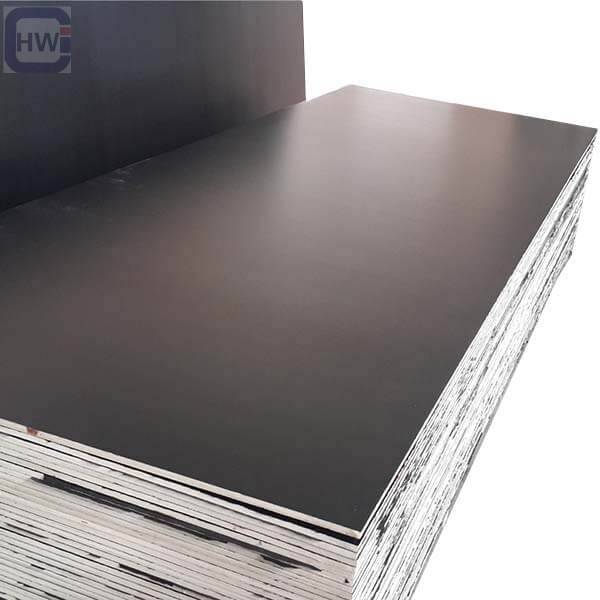

Black Film-Faced Plywood

Film Faced Plywood is also called Formwork Plywood, Shuttering Plywood, Concrete formwork. Film faced plywood is the special plywood with two sides coated with wearable and water proof film. The film is adhesive impregnated paper, which are different from melamine paper overlay, PVC, MDO and HDO. The function of the film is to protect the inside wood from moisture, water, weather and extend the plywood’s service life. Film Faced Plywood is an exterior plywood used in building and construction projects……

-

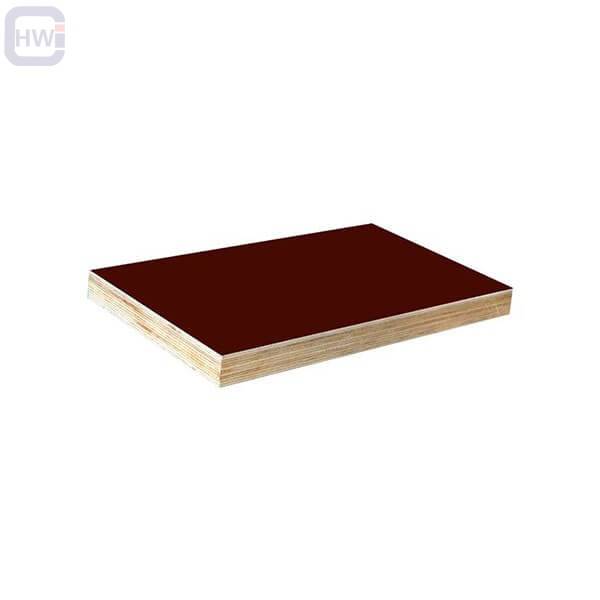

Brown Film Faced Plywood

Film Faced Plywood is also called Formwork Plywood, Shuttering Plywood, or Concrete formwork. Film-faced plywood is a special plywood with two sides coated with a wearable and waterproof film. The film is adhesive-impregnated paper, which is different from melamine paper overlay, PVC, MDO, and HDO. The function of the film is to protect the inside wood from moisture, water, and weather and extend the plywood’s service life. Film Faced Plywood is exterior plywood used in building and construction projects……

-

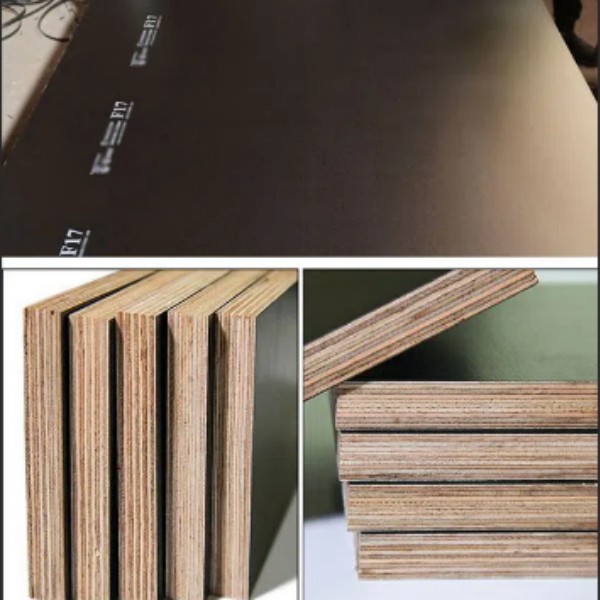

F17 Structural Formply

FORMPLY F17 1800 X 1200 X 17MM PLYWOOD

F17 Formply, 17mm Formply 1200*1800mm

Size: 1220*1800mm, 1200*2400mm

Thickness: 17mm

Core material: Hardwood, Birch, Pine, etc

Glue: Phenolic glue(72 hours in boiling water)

Face/Back: Dynea Film, Black/Brown Film, Class 2

Moisture Content: 6-10%

Application: Concrete Formwork, Construction, Wagon building, etc

-

F17 Structural Formply

FORMPLY F17 1800 X 1200 X 17MM PLYWOOD

F17 Formply, 17mm Formply 1200*1800mm

Size: 1220*1800mm, 1200*2400mm

Thickness: 17mm

Core material: Hardwood, Birch, Pine, etc

Glue: Phenolic glue(72 hours in boiling water)

Face/Back: Dynea Film, Black/Brown Film, Class 2

Moisture Content: 6-10%

Application: Concrete Formwork, Construction, Wagon building, etc

-

FORMPLY F17 1800 X 1200 X 17MM FORMWORK PLYWOOD

FORMPLY F17 1800 X 1200 X 17MM PLYWOOD

F17 Formply, 17mm Formply 1200*1800mm

Size: 1220*1800mm, 1200*2400mm

Thickness: 17mm

Core material: Hardwood, Birch, Pine, etc

Glue: Phenolic glue(72 hours in boiling water)

Face/Back: Dynea Film, Black/Brown Film, Class 2

Moisture Content: 6-10%

Application: Concrete Formwork, Construction, Wagon building, etc

-

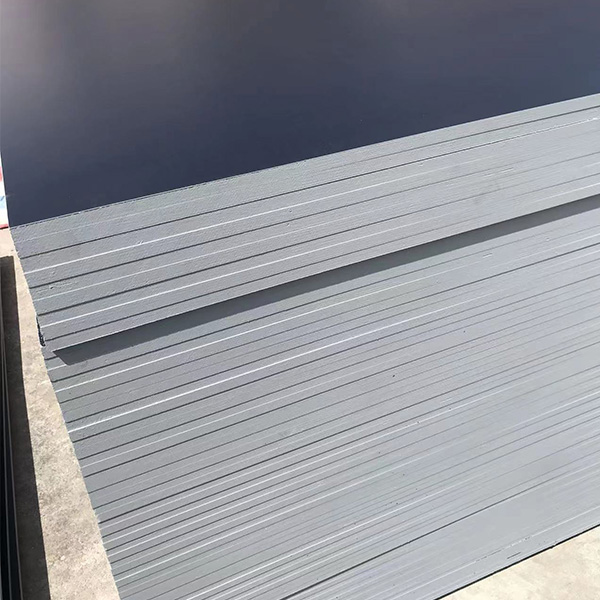

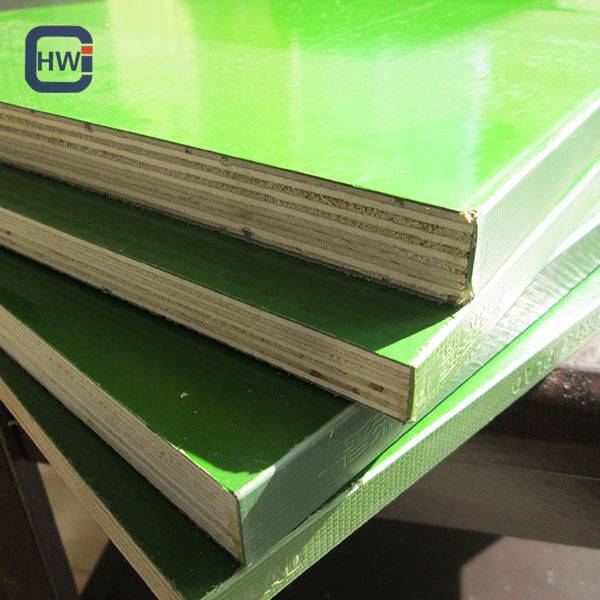

Green PP Plastic Faced Plywood

- Water and Moisture Resistance: The polypropylene coating provides excellent resistance to water and moisture, making this plywood ideal for outdoor, marine, or humid environment applications, where traditional wood would degrade.

- Durability and Wear Resistance: The plastic face is highly resistant to wear, tear, and abrasion, ensuring a longer lifespan and maintaining its appearance over time, even under heavy use.

- Chemical Resistance: This plywood is resistant to a range of chemicals, making it suitable for laboratory, industrial, or agricultural applications where chemical exposure is a concern.

- Easy Maintenance and Hygiene: The smooth surface of the PP coating is easy to clean and sanitize, which is beneficial for applications in healthcare, food service, or any area where hygiene is a priority.

- Versatility in Applications: Despite its specialized coating, PP plastic-faced plywood retains the workability of traditional plywood, allowing it to be cut, drilled, and shaped easily for a variety of uses, from construction and automotive to furniture making.

-

HW Black Oversize Film-Faced Plywood

Film Faced Plywood is also called Formwork Plywood, Shuttering Plywood, or Concrete formwork. Film-faced plywood is a special plywood with two sides coated with a wearable and waterproof film. The film is adhesive-impregnated paper, which is different from melamine paper overlay, PVC, MDO, and HDO. The function of the film is to protect the inside wood from moisture, water, and weather and extend the plywood’s service life. Film Faced Plywood is exterior plywood used in building and construction projects……

-

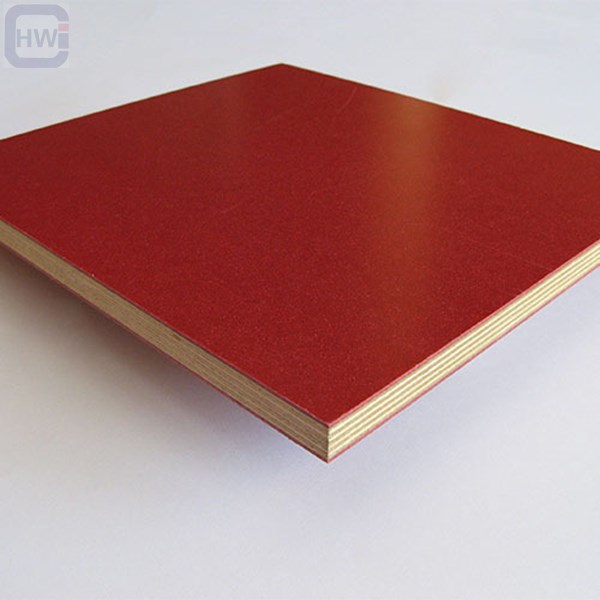

Red Film Faced Plywood

Material and Composition: Red Film Faced Plywood is made from layers of wood veneers bonded together with a strong adhesive. The distinctive feature of this plywood is its red-colored film coating on one or both sides. This film is typically made from a phenolic resin, which imparts strength and durability to the plywood.- Durability and Moisture Resistance: This type of plywood is highly durable and resistant to moisture, thanks to its resin-coated surface. The film facing acts as a barrier against water and humidity, making it an ideal choice for outdoor and construction applications where exposure to the elements is a concern.

- Appearance and Finish: The red film coating not only provides protection but also gives the plywood a smooth and uniform surface. This makes it ideal for applications where a consistent and aesthetic appearance is desired. The red color also makes it easily identifiable on construction sites.

- Strength and Stability: Red Film Faced Plywood is known for its high strength and stability. The cross-grained structure of the plywood distributes the load evenly, enhancing its load-bearing capacity. This makes it suitable for use in demanding applications such as formwork in concrete construction.

- Applications: This plywood is commonly used in the construction industry, especially for making concrete formwork, scaffolding, hoardings, and outdoor furniture. Its ability to withstand harsh conditions and repeated use makes it a cost-effective and reliable choice for builders and contractors.

Formwork Plywood Introduction

Formwork plywood is a type of engineered wood panel that is specifically designed and manufactured for use in concrete formwork applications. The plywood we use is made with layers of wood veneer that are bonded together with waterproof glue. This makes a very strong, durable sheet that can withstand the pressure and moisture of concrete pouring. It is typically made from birch, which is stronger and more durable than pine or spruce. The panels are also treated with special coatings and finishes that protect them from water damage and extend their lifespan. Plywood comes in a range of thicknesses, sizes, and grades to suit different construction projects. When a construction project involves a lot of concrete, it's often best to use fast-hardening concrete.Formwork Plywood Feature

- Strength and durability: Concrete plywood is made from high-quality hardwood veneers. These ensure that it can withstand the pressure and weight of poured concrete.

- Water resistance: Plywood can be finished with special coatings to protect it from water and moisture. This keeps it from warping, swelling, or deteriorating over time.

- Smooth surface: The plywood has a smooth surface finish that ensures a high-quality, smooth finish to the concrete after it has cured.

- Easy to cut and shape: It is easy to cut and shape, allowing it to be quickly and easily customized to fit specific formwork requirements.

- Reusability: This plywood is reusable, making it a cost-effective option for construction projects.

- Availability: A variety of thicknesses and sizes make plywood suitable for a range of formwork applications.

- Sustainability: Plywood made from sustainably sourced wood is an environmentally-friendly option.