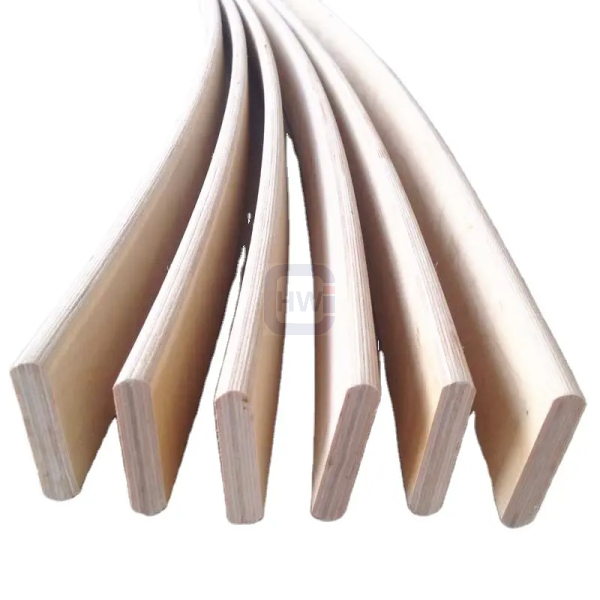

Latoflex Bed Slat Sprung Bed Slats Wooden Slat For Bed

Product Description

Laminated veneer lumber (LVL)

Laminated Veneer Lumber (LVL) is another type of plywood. It is made of multiple layers of thin wood (along the same direction as wood fiber), assembled with adhesives through hot-pressing.

Currently, the core veneers are mainly Poplar, Eucalyptus, Eucalyptus, and Poplar mixed, Paulownia and Poplar mixed, etc.

LVL Specifications

|

Product name

|

100% Birch 8-40mm Bed Slats lat flex for natural adjustable bed

|

||

|

Branding

|

HW

|

||

|

Core material

|

birch, etc.

|

||

|

Surface material

|

birch, etc.

|

||

|

Size range

|

T:6-25mm,W:30-120mm,L:300-2200mm

|

||

|

Tolerance

|

Thickness:±0.5mm,Width:±1mm,Length:±1mm

|

||

|

Glue

|

E1/E0

|

||

|

Moisture

|

<14%

|

||

|

Shape

|

Curved(R4000)

|

||

|

Port

|

Qingdao/Lianyungang

|

||

|

Package

|

Pallet with plastic film and packing belt.

|

||

|

Application

|

bed/sofa etc.

|

||

Main Features

1. Excellent Dimensional Stability

The laminated structure of LVL greatly reduces the possibility of warping and twisting, so the dimensional stability of LVL is very good.

2. High Strength

As the LVL is made of veneers that are cut by a rotary cutting machine and assembled with adhesives through hot-pressing. Therefore, it can reduce the influence of strength defects, and become a kind of engineered material with reliable strength.

3. Flexible Size

For special manufacturing methods, the size of LVL can be not restricted by log size or veneer specification, so the sizes are flexible and can be freely chosen.

4. Fumigation Free

For the hot-pressing process in LVL production, LVL can be exported free of fumigation.

5. Low Cost

LVL production could use small-diameter wood, bentwood, and short logs. Therefore, the output rate could reach 60% to 70%. In other words, LVL could produce a value-added effect by using small materials and inferior materials.

Material of Bed Slats Latoflex:

|

– Bed slats curved /flat 100% poplar – Bed slats curved/flat 100% poplar with structured paper – Bed slats curved/flat 100% poplar with face and back birch – Bed slats curved/flat 100% poplar with face and back engineer veneer – Bed slats curved/flat 100% birch natural glue/glue – Bed slats curved/flat 100% birch with structured paper |

Delivery Instructions

| Packing | Standard Export Pallet Packing | Inner Packing | The pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | The pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/20cbm | ||

| 40’GP | 16pallets/40cbm | |||

| 40’HQ | 18pallets/40cbm | |||

Packaging and Containerization

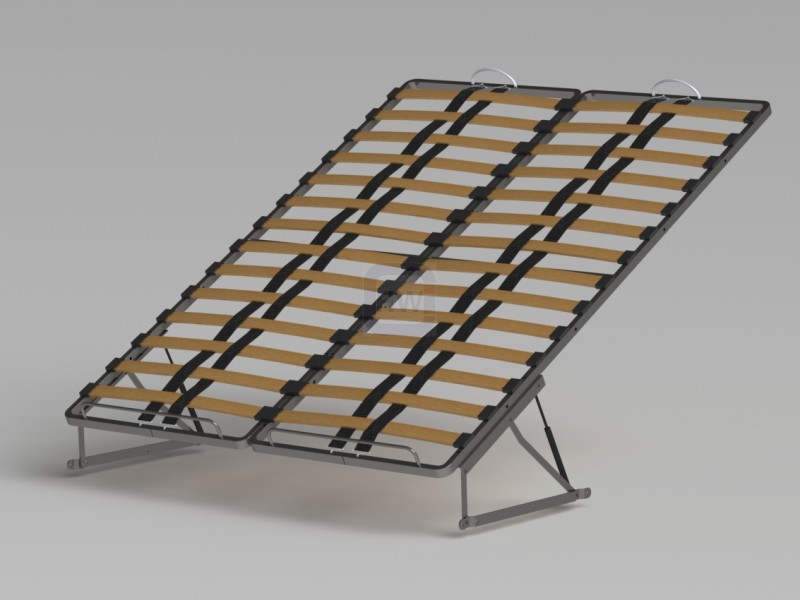

Application of Bed Slats Latoflex:

For interior applications as high-quality Bed/ Sofa/ furniture/roofing panel/underlayment/subfloor; for exterior applications as high-quality building materials/fences/signs and so on .

FAQ

Q: What is the maximum weight capacity of Latoflex bed slats?

A: The weight capacity of Latoflex bed slats varies depending on the specific model, but they are typically designed to support weights of up to 120 kg (264 lbs) per slat.

Q: Are Latoflex bed slats suitable for all types of mattresses?

A: Yes, Latoflex bed slats are suitable for use with all types of mattresses, including foam, latex, and innerspring mattresses.

Q: Can I adjust the firmness of Latoflex bed slats?

A: Yes, Latoflex bed slats are adjustable, allowing you to customize the firmness and support of your bed to your specific needs.

Q: Are Latoflex bed slats easy to install?

A: Yes, Latoflex bed slats are easy to install and can be used with a variety of bed frames.

Q: Can I use Latoflex bed slats with a bed frame that already has slats?

A: Yes, Latoflex bed slats can be used with bed frames that already have slats. Simply remove the existing slats and replace them with the Latoflex slats.