HW Formwork LVL Beam, Structure LVL

HW Formwork LVL (Laminated Veneer Lumber) beam and Structure LVL are both types of engineered wood products that are commonly used in construction applications.

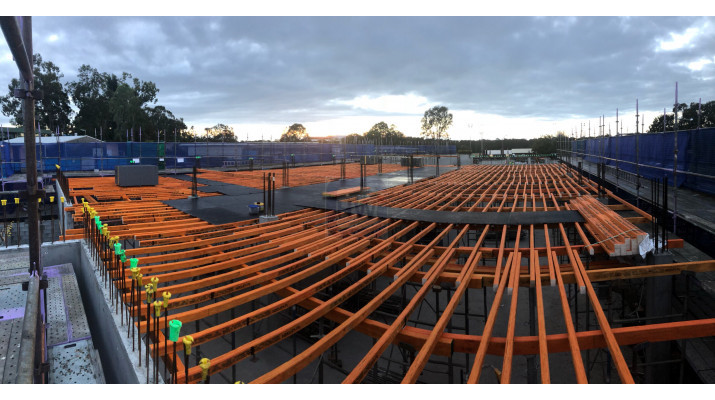

HW Formwork LVL beam is specifically designed for use in formwork applications, which are used to create the molds that concrete is poured into. The beam is made by bonding together several layers of thin wood veneers with adhesives and then shaping them into a beam shape. This creates a strong and durable beam that is able to support the weight of the concrete and the formwork system. HW Formwork LVL beams are typically lightweight and easy to handle, which can help reduce construction time and costs.

Structure LVL, on the other hand, is used in a wide variety of structural applications, including framing, beams, and columns. It is also made by bonding together several layers of thin wood veneers with adhesives, but it is designed to be stronger and more durable than HW Formwork LVL beams. Structure LVL is available in a range of sizes and grades, which allows it to be used in a variety of construction applications.

Product Description

Full Pine LVL beam, LVL framing, LVL rafters or Strand lumber/Engineered lumber/Wood beam of engineered wood for LVL molding Structural LVL

HW structural laminated veneer lumber (LVL) has been manufactured in accordance with AS/NZS 4357 with properties determined in accordance with AS/NZS 4063.2 and therefore complies with the requirements for structural design in accordance with AS1720.1

HW LVL terminator is available in all sizes and is part of the Carter Holt Harvey Terminator range. HW H2-S Terminator is treated against termites south of the Tropic of Capricorn. The treatment is applied to the glue line during manufacture to achieve full termite protection to the core of the beam. No further sealing is required on cut ends, holes, or notches. Other treatment levels are available from suppliers on request, but treatment is limited to above-ground use. hySPAN cannot be readily treated for in-ground contact applications.

HW LVL is manufactured using an ‘A’ Bond with less than 0.5mg/l Formaldehyde (equivalent to E0) emissions from the final product.

laminated veneer lumber type structural lvl

For quality assurance, the HW range is manufactured with independent audit processes and product certification. Carter Holt Harvey ensures that its wood is legally sourced from managed forests and offers FSC’s Chain of Custody certification upon request.

HW LVL is produced with a structural grade face and is not generally used in appearance applications and at the time of dispatch from the manufacturing site has a moisture content of between 8-15%.

Size Range

|

SIZE |

35mm |

45mm |

63mm |

75mm |

|

90 mm |

A |

A |

||

|

130 mm |

A |

A |

A |

|

|

150 mm |

A |

A |

A |

A |

|

170 mm |

A |

A |

A |

|

|

200 mm |

A |

A |

A |

|

|

240 mm |

A |

A |

||

|

300 mm |

A |

A |

A |

|

|

360 mm |

A |

A |

||

|

400 mm |

A |

A |

A |

|

|

450 mm |

A |

|||

|

525 mm |

A |

A |

||

|

600 mm |

A |

Advantage of HW structural LVL

- Strength and Durability:Both HW Formwork LVL beam and Structure LVL are engineered to be strong and durable, with a solid core made up of several layers of wood veneers or fibers. This makes them less likely to warp or crack, even when exposed to changes in temperature and humidity.

2. Stability:Because of their construction, HW Formwork LVL beam and Structure LVL are more stable than solid wood, making them less likely to expand or contract with changes in temperature and humidity. This can be particularly important for construction projects where stability is critical.

3. Versatility: HW Formwork LVL beam and Structure LVL can be used in a wide range of construction applications, from formwork and framing to beams and columns.

4. Cost-Effective: Both HW Formwork LVL beam and Structure LVL are typically less expensive than solid wood, making them a more cost-effective option for construction projects.

5. Easy to Work With HW Formwork LVL beam and Structure LVL can be easily cut and shaped with standard woodworking tools, making them a popular choice for construction projects of all sizes.

Application of HW structural LVL

LVL is particularly well suited to the following applications

Rafters and joists

Lintels, beams, and framing members

Truss chords

Portal frames

I-beams

Box-beams

Scaffold planks

Formwork

Panels of LVL are cut into structural members which have high strength and stiffness.

LVL is suited to structural applications such as beams, rafters, and columns in a wide range of buildings including houses, and commercial, industrial, and rural structures. Some special LVL has a small number of veneers laid perpendicularly (cross-banded).

In commercial or industrial structures it is often used as a wood-based alternative to structural steel or reinforced concrete.

Packaging and Containerization

FAQ

Q: What is HW Formwork LVL beam?

A: HW Formwork LVL beam is an engineered wood product that is specifically designed for use in formwork applications, which are used to create the molds that concrete is poured into. The beam is made by bonding together several layers of thin wood veneers with adhesives and then shaping them into a beam shape.

Q: What is Structure LVL?

A: Structure LVL is an engineered wood product that is used in a wide variety of structural applications, including framing, beams, and columns. It is made by bonding together several layers of thin wood veneers with adhesives, creating a strong and durable product.

Q: How are HW Formwork LVL beam and Structure LVL different from solid wood?

A: HW Formwork LVL beam and Structure LVL are engineered wood products that are designed to be stronger, more stable, and more cost-effective than solid wood. They are also less likely to warp or crack, making them a popular choice for construction applications.

Q: Are HW Formwork LVL beam and Structure LVL environmentally friendly?

A: Both HW Formwork LVL beam and Structure LVL can be environmentally friendly options for construction projects, as they can be made from sustainably harvested wood and can reduce waste by using smaller pieces of wood that might not be suitable for solid wood construction.

Q: Can HW Formwork LVL beam and Structure LVL be used in outdoor applications?

A: HW Formwork LVL beam and Structure LVL can be used in outdoor applications, but it is important to choose products that are specifically designed for exterior use and are treated to resist moisture and decay.