LVL E13 90 X 45 H2

LVL E13 90 X 45 H2 refers to a specific type of Laminated Veneer Lumber (LVL) that has been designed and manufactured according to certain specifications.

The “LVL E13” indicates that the product has been rated as having a modulus of elasticity (MOE) of 13,000 MPa, which is a measure of its stiffness and strength. This rating is often used to determine the suitability of the product for different structural applications.

The “90 X 45” refers to the dimensions of the LVL board, with a width of 90 millimeters and a thickness of 45 millimeters. These dimensions can vary depending on the specific application and the manufacturer’s specifications.

Finally, the “H2” refers to the level of treatment that the LVL has received to protect it against insect attack and fungal decay. H2 is a standard level of treatment that is suitable for use in dry, interior applications.

Product Description of LVL E13 90 X 45 H2:

Full Pine LVL beam, LVL framing, LVL rafters or Strand lumber/Engineered lumber/Wood beam of engineered wood for LVL molding Structural LVL

HW structural laminated veneer lumber (LVL) has been manufactured in accordance with AS/NZS 4357 with properties determined in accordance with AS/NZS 4063.2 and therefore complies with the requirements for structural design in accordance with AS1720.1

HW LVL terminator is available in all sizes and is part of the Carter Holt Harvey Terminator range. HW H2-S Terminator is treated against termites south of the Tropic of Capricorn. The treatment is applied to the glue line during manufacture to achieve full termite protection to the core of the beam. No further sealing is required on cut ends, holes, or notches. Other treatment levels are available from suppliers on request, but treatment is limited to above-ground use. hySPAN cannot be readily treated for in-ground contact applications.

HW LVL is manufactured using an ‘A’ Bond with less than 0.5mg/l Formaldehyde (equivalent to E0) emissions from the final product.

laminated veneer lumber type structural lvl

For quality assurance, the HW range is manufactured with independent audit processes and product certification. Carter Holt Harvey ensures that its wood is legally sourced from managed forests and offers FSC’s Chain of Custody certification upon request.

HW LVL is produced with a structural grade face and is not generally used in appearance applications at the time of dispatch from the manufacturing site has a moisture content of between 8-15%.

Size Range

|

SIZE |

35mm |

45mm |

63mm |

75mm |

|

90 mm |

A |

A |

||

|

130 mm |

A |

A |

A |

|

|

150 mm |

A |

A |

A |

A |

|

170 mm |

A |

A |

A |

|

|

200 mm |

A |

A |

A |

|

|

240 mm |

A |

A |

||

|

300 mm |

A |

A |

A |

|

|

360 mm |

A |

A |

||

|

400 mm |

A |

A |

A |

|

|

450 mm |

A |

|||

|

525 mm |

A |

A |

||

|

600 mm |

A |

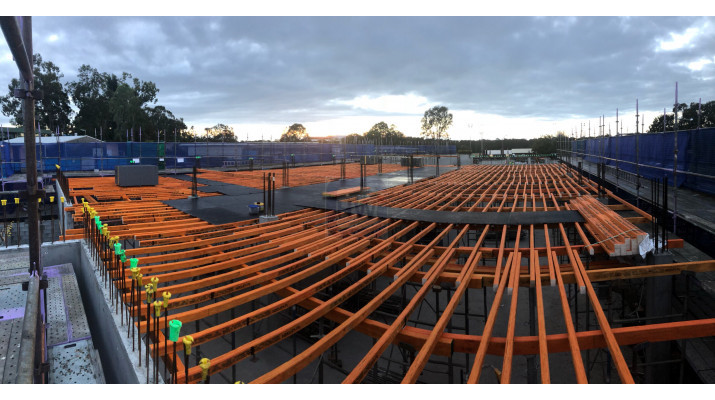

Our LVL formwork beams are painted in colors for moisture protection and ready identification. HW has chamfered edges for ease of handling and a water-repellent paint finish. HW represents a substantial improvement over conventional timber beams and an easier-to-use, more convenient alternative to other materials. It is strong, durable, reliable, and reusable.

Advantage of LVL E13 90 X 45 H2:

1. High strength and stiffness: LVL E13 90 X 45 H2 has a high modulus of elasticity (MOE) of 13,000 MPa, which means it is strong and rigid. This makes it a good choice for structural applications where strength and stiffness are important.

2. Consistent performance: Because LVL is manufactured by bonding together multiple layers of thin wood veneers with adhesives, it has a more consistent performance than solid timber. This means it is less likely to warp, twist, or split, providing greater stability and durability over time.

3. Lightweight: LVL E13 90 X 45 H2 is lighter than solid timber, making it easier to handle and transport on construction sites. This can help to reduce labor costs and increase efficiency.

4. Versatile: LVL E13 90 X 45 H2 can be used for a wide range of applications, including as a replacement for traditional timber framing, roof and floor joists, and wall studs. This versatility makes it a popular choice for many different types of construction projects.

5. Sustainable: LVL is made from sustainably managed plantation-grown timber, making it an environmentally friendly choice for construction projects.

Application of LVL E13 90 X 45 H2:

LVL is particularly well suited to the following applications

Rafters and joists

Lintels, beams, and framing members

Truss chords

Portal frames

I-beams

Box-beams

Scaffold planks

Formwork

Panels of LVL are cut into structural members which have high strength and stiffness.

LVL is suited to structural applications such as beams, rafters, and columns in a wide range of buildings including houses, and commercial, industrial, and rural structures. Some special LVL has a small number of veneers laid perpendicularly (cross-banded).

In commercial or industrial structures it is often used as a wood-based alternative to structural steel or reinforced concrete.

Packaging and Containerization of LVL E13 90 X 45 H2:

FAQ

Q: What are some common applications for LVL E13 90 X 45 H2?

A: LVL E13 90 X 45 H2 is commonly used in structural applications such as roof and floor framing, wall framing, and as support beams and columns in residential and commercial construction projects.

Q: How is LVL E13 90 X 45 H2 different from traditional timber framing?

A: LVL E13 90 X 45 H2 is a stronger, more stable, and more consistent material than traditional timber framing. It is also lighter in weight, which can make it easier to handle and install on construction sites.

Q: What are some advantages of using LVL E13 90 X 45 H2 in construction?

A: Some advantages of using LVL E13 90 X 45 H2 in construction include its high strength and stiffness, consistent performance, lightweight nature, versatility, and sustainability.

Q: Is LVL E13 90 X 45 H2 environmentally friendly?

A: Yes, LVL E13 90 X 45 H2 is an environmentally friendly choice for construction projects because it is made from sustainably managed plantation-grown timber.

Q: How is LVL E13 90 X 45 H2 manufactured?

A: LVL E13 90 X 45 H2 is manufactured by bonding together multiple layers of thin wood veneers with adhesives under heat and pressure. The resulting product is strong, stable, and consistent in performance.