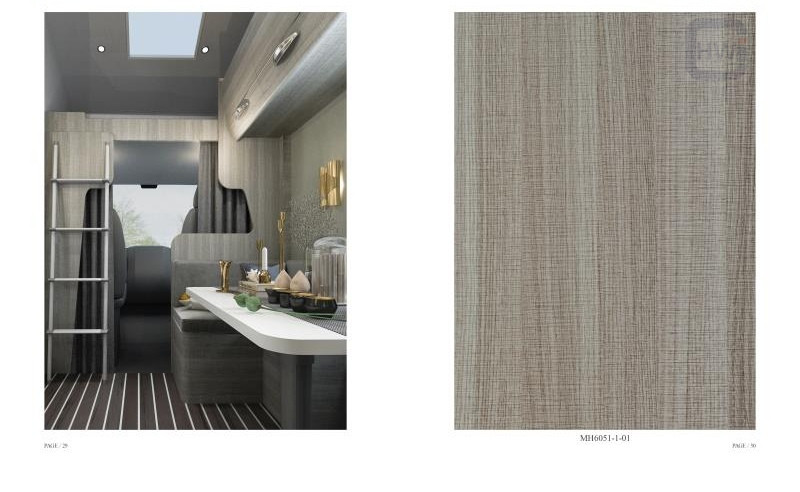

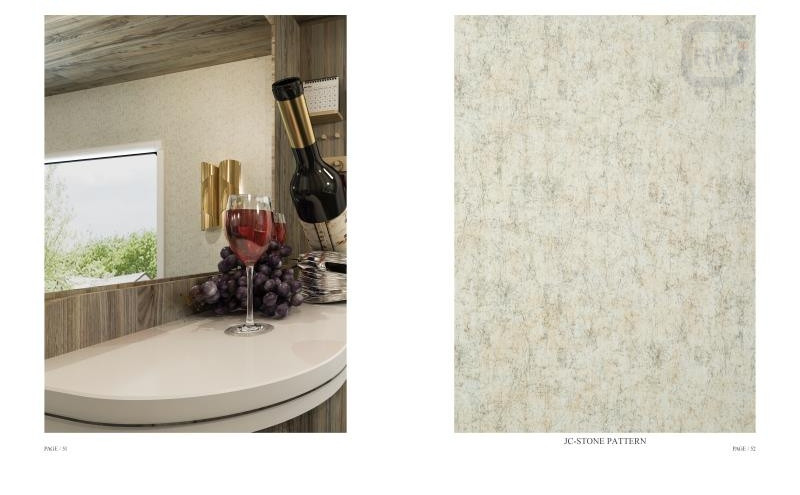

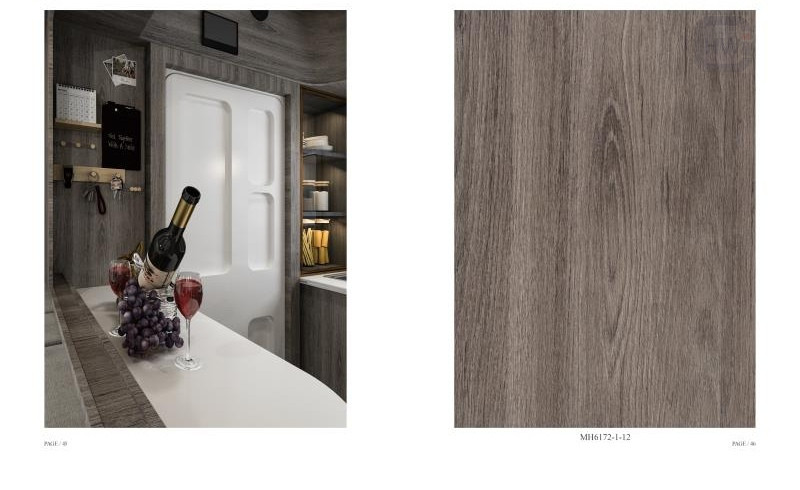

HW Paulownia Core Plywood, Flexible Plywood

Paulownia Multilayer

High quality

HW is manufactured using the latest plywood technology paired with over twenty years of plywood knowledge and expertise.

Lightweight

Made with 100% paulownia core, HW is 30% lighter than other commonly sourced RV/Campervan/Caravan panel substrates.

Sustainable

Sourced from fast-growing Chinese plantations and sustainably managed forests for a stable, reliable supply chain.

- The material is light and tough

To evaluate the quality of wood, bulk density, and strength are important standards. The higher the strength is, the lighter the bulk density is. Paulownia wood is one of the lightest wood on the earth. Its air-dry density is 0.23-0.40 g / cm3, which is about 40% lighter than ordinary wood. Its biggest advantage is that it is light and tough.

- No warping, no deformation

Because of its small coefficient of shrinkage, the trees do not bend and do not warp, and are not deformed.

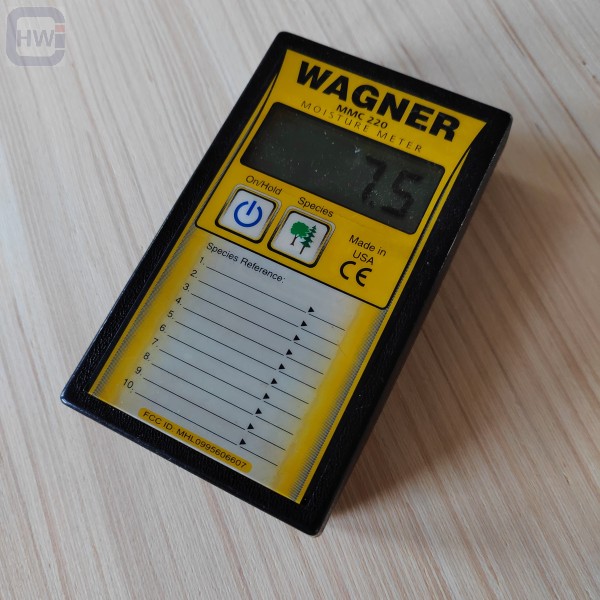

- Moisture-proof

The dried tung tree is not easy to absorb moisture and moisture and has a high degree of preservation.

- Fire resistance

The thermal conductivity of Paulownia wood is smaller than other ones. Generally, the combustion point of wood is about 270 degrees, and the burning point of Paulownia wood is 425 degrees, which is a rare feature.

- Wear resistance

Although the Paulownia wood is light, it is not easy to wear. The Paulownia wood is used as an air box, and the pull rod is worn back and forth, but the box plate is not easy to wear.

- Beautiful texture and bright color

Paulownia wood has a bright, beautiful, and delicate texture with silk, and the natural pattern is very good. - Strong sound guidance

Paulownia wood is indispensable for making musical instruments. Regardless of weather changes, it can stabilize the timbre, so it is called “Qing Tong”. For example, Yangqin, Pipa, Liuqin, and even Qinhu are all made of paulownia. - Easy to carve and dye

Paulownia wood is not easy to split, but the wood is soft, easy to process, easy to carve, and easy to dye. It can be used as a beam, purlin, door and window, ceiling, tile board, room partition, and so on. Paulownia Core Plywood is used for Caravan/RV/Touring Car/Camper Vans Interiors, as well as Furniture Applications.

Advantages

HW Paulownia Core Plywood:

1. Lightweight: Paulownia wood is known for its lightweight nature, making this type of plywood ideal for applications where weight is a concern.

2. High Strength-to-Weight Ratio: Despite its lightweight nature, HW Paulownia Core Plywood is strong and durable, with a high strength-to-weight ratio.

3. Low Moisture Content: The low moisture content of Paulownia wood means that it is resistant to warping, cracking, and splitting, making it a reliable and long-lasting material.

4. Good Insulation: HW Paulownia Core Plywood has excellent insulation properties, making it suitable for use in environments where temperature and humidity need to be controlled.

Flexible Plywood:

1. Highly Flexible: Flexible Plywood can be bent and curved to fit various shapes and contours, making it ideal for applications where a rigid material cannot be used.

2. Durable: Flexible Plywood is made by bonding several thin layers of wood veneer together using a strong adhesive, which makes it highly durable and resistant to cracking or breaking.

3. Versatile: Flexible Plywood can be used for a range of applications, including in the construction of curved walls, ceilings, and furniture.

4. Easy to Work: Flexible Plywood can be easily cut, shaped, and sanded, making it easy to work with and customize for specific projects.

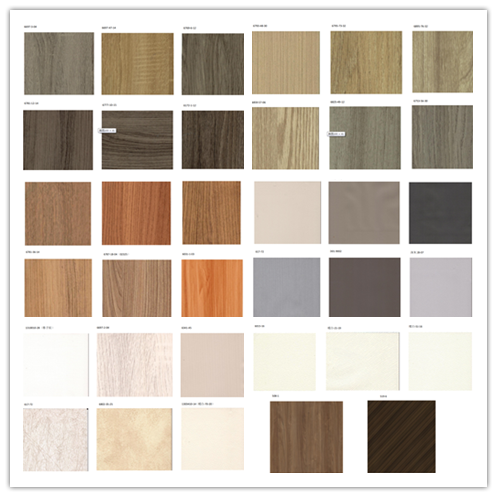

Surface Material

Covered Paper, PVC, HPL, etc. ( (Gray, Yellow, White, Wood Grain, Stone Grain)

Delivery Instructions

| Packing | Standard Export Pallet Packing | Inner Packing | The pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | The pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/50cbm | |||

Packaging and Containerization

Application

HW Paulownia Core Plywood:

1. Furniture: HW Paulownia Core Plywood is commonly used in the manufacturing of lightweight furniture due to its strength, durability, and low weight.

2. Cabinetry: Due to its excellent insulation properties, HW Paulownia Core Plywood is used in cabinets and other interior decoration applications.

3. Model making: HW Paulownia Core Plywood is a popular material for model making due to its lightweight and strength.

4. Musical instruments: The low weight and excellent acoustic properties of HW Paulownia Core Plywood make it suitable for use in musical instrument manufacturing.

Flexible Plywood:

1. Curved walls and ceilings: Flexible Plywood is commonly used in the construction of curved walls and ceilings due to its high flexibility.

2. Furniture: Flexible Plywood is also used in the manufacturing of furniture that requires a curved or bent shape.

3. Packaging: Flexible Plywood is used in packaging and crating applications due to its ability to bend and conform to different shapes.

4. Boat building: Flexible Plywood is used in the manufacturing of boats and other marine applications where the plywood needs to conform to the shape of the hull.

FAQ

Q: What is HW Paulownia Core Plywood?

A: HW Paulownia Core Plywood is a type of plywood made from high-quality Paulownia wood, which is lightweight, strong, and has a low moisture content. This type of plywood is ideal for use in furniture, cabinetry, and interior decoration.

Q: What is Flexible Plywood?

A: Flexible Plywood is a type of plywood that is highly flexible and can be bent and curved to fit various shapes and contours. It is typically used for applications where a rigid material cannot be used, such as in the construction of curved walls, ceilings, and furniture.

Q: What are the advantages of HW Paulownia Core Plywood?

A: The advantages of HW Paulownia Core Plywood include its lightweight nature, high strength-to-weight ratio, low moisture content, and excellent insulation properties. It is also durable and resistant to warping, cracking, and splitting.

Q: What are the advantages of Flexible Plywood?

A: The advantages of Flexible Plywood include its high flexibility, durability, versatility, and ease of use. It can be easily cut, shaped, and sanded, and is suitable for a range of applications, including the construction of curved walls, ceilings, and furniture.

Q: What applications are HW Paulownia Core Plywood suitable for?

A: HW Paulownia Core Plywood is suitable for a range of applications, including furniture, cabinetry, interior decoration, and any other applications where a lightweight, strong, and durable material is required.