Sliced Veneer Introduction

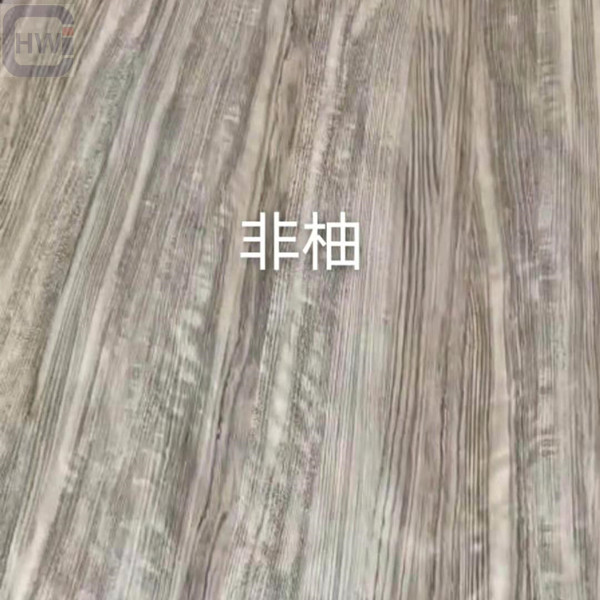

A sliced veneer is a type of thin wood sheet that is created by slicing a log or timber into very thin layers using a specialized machine called a veneer slicer. These thin layers or slices of wood are then dried and glued together to form larger panels or sheets.

The veneer is commonly used in the furniture, cabinetry, and interior design industries as a decorative surface material. It is also used in construction for paneling, flooring, and ceiling tiles. This kind of veneer offers many advantages over solid wood, including flexibility, stability, and uniformity in grain and color.

The thickness of the veneer can vary depending on the application and the desired effect. Generally, it ranges from 0.2 to 6 millimeters. The type of wood used for the veneer can also vary, including both hardwoods and softwoods. Popular hardwoods used for the veneers include oak, maple, cherry, and walnut, while popular softwoods include pine, spruce, and fir.

Overall, this veneer is a versatile and cost-effective material that offers many benefits and applications.

Sliced Veneer Feature

- Thickness: The veneer is a very thin layer of wood, typically ranging from 0.2 to 6 millimeters in thickness.

- Uniformity: It has a uniform grain and color, which makes it ideal for applications where consistency is important, such as furniture and cabinetry.

- Flexibility: The veneer is more flexible than solid wood, which makes it easier to work with and shapes into various forms.

- Stability: This kind of veneer is more stable than solid wood, meaning it is less prone to warping, shrinking, or expanding due to changes in temperature and humidity.

- Cost-effective: It is often more affordable than solid wood, especially for exotic or rare woods, as it allows for more efficient use of the raw material.

- Aesthetics: Veneer is a popular decorative surface material due to its natural wood grain and unique patterns, which can be enhanced through staining, painting, or other finishing techniques.

- Environmentally friendly: It is an eco-friendly option as it uses less wood than solid wood and can be produced from sustainably harvested forests.

FAQ

Q: What is the difference between a sliced veneer and a rotary cut veneer?

A: Veneer is produced by slicing a log into thin layers with a veneer slicer, while the rotary-cut veneer is produced by peeling a log into a continuous sheet using a lathe. Sliced veneer has a more uniform grain pattern, while rotary-cut veneer has a wilder and more irregular grain pattern.

Q: Can sliced veneer be stained or painted?

A: Yes, veneer can be stained or painted just like solid wood. The natural grain patterns of the veneer can be enhanced or altered through various finishing techniques.

Q: Is sliced veneer as strong as solid wood?

A: While the veneer is thinner than solid wood, it is still strong and durable when properly glued and laminated. In fact, a sliced veneer can be even stronger than solid wood due to its stability and uniformity.

Q: Can sliced veneer be used for outdoor applications?

A: Sliced veneer is not recommended for outdoor applications as it is not as weather-resistant as solid wood or other outdoor-grade materials. It is best suited for indoor applications where it can be protected from moisture and direct sunlight.

Q: How is sliced veneer produced?

A: Sliced veneer is produced by feeding a log or timber through a veneer slicer, which cuts the log into thin layers or slices. These slices are then dried, sorted, and glued together to form larger sheets or panels. The veneer can then be sanded, finished, and cut to size for use in various applications.