Veneer

-

Customizable natural okoume veneer for plywood

Customizable natural okoume veneer

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-14pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Material: Okoume Veneer/Rotary Cut Veneer/custom

- Size:1270*2500mm,1270*2200mm, 1270*1900mm,970*200mm, 970*1900mm or customize

- Thickness: 0.15mm-1.5mm

- Moisture Content: <12%

-

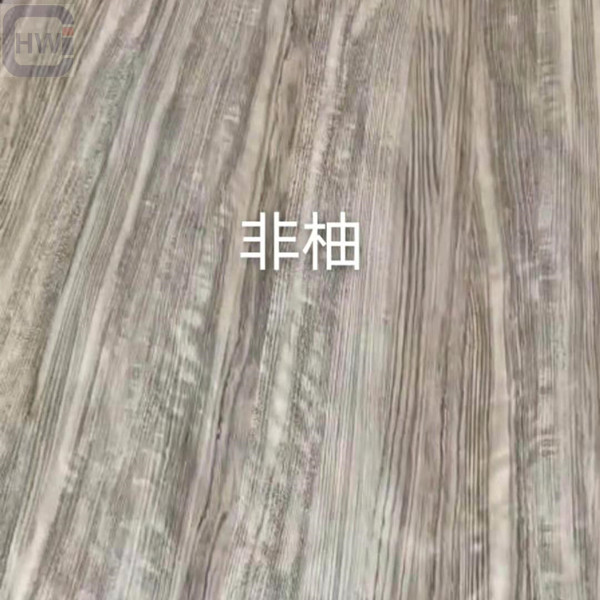

Engineered wood veneer/ reconstituted wood veneer/recon veneer

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-14pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Material: Sliced Veneer/Engineered Veneer/custom

- Size:1270*2500mm,1270*2200mm, 1270*1900mm,970*200mm, 970*1900mm or customize

- Thickness: 0.15mm-1.5mm

- Glue: E0/E1

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Moisture Content: <12%

-

HW Engineered Veneer and Sliced Veneer

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-14pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Material: Rotary Veneer/Engineered Veneer/custom

- Size:1270*2500mm,1270*2200mm, 1270*1900mm,970*200mm, 970*1900mm or customize

- Thickness: 0.15mm-1.5mm

- Moisture Content: <12%

-

HW Engineered Wood Veneer, EV, Sliced Veneer

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-14pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Material: Rotary Veneer/Engineered Veneer/custom

- Size:1270*2500mm,1270*2200mm, 1270*1900mm,970*200mm, 970*1900mm or customize

- Thickness: 0.15mm-1.5mm

- Glue: E0/E1

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Moisture Content: <12%

-

HW Sliced African Teak Veneer

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-14pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Material: Rotary Veneer/Engineered Veneer/custom

- Size:1270*2500mm,1270*2200mm, 1270*1900mm,970*200mm, 970*1900mm or customize

- Thickness: 0.15mm-1.5mm

- Moisture Content: <12%

-

HW Sliced Red Rose Veneer

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-14pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Material: Rotary Veneer/Engineered Veneer/custom

- Size:1270*2500mm,1270*2200mm, 1270*1900mm,970*200mm, 970*1900mm or customize

- Thickness: 0.15mm-1.5mm

- Moisture Content: <12%

-

HW Walnut Veneer

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-14pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Material: Rotary Veneer/Engineered Veneer/custom

- Size:1270*2500mm,1270*2200mm, 1270*1900mm,970*200mm, 970*1900mm or customize

- Thickness: 0.15mm-1.5mm

- Moisture Content: <12%

-

Recon Veneer

- Recon Veneer

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-14pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Material: Sliced Veneer/Engineered Veneer/custom

- Size:1270*2500mm,1270*2200mm, 1270*1900mm,970*200mm, 970*1900mm or customize

- Thickness: 0.15mm-1.5mm

- Glue: E0/E1

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Moisture Content: <20%

-

Red Face Veneer Decorative Natural Wood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-14pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Material: Okoume Veneer/Rotary Cut Veneer/custom

- Size:1270*2500mm,1270*2200mm, 1270*1900mm,970*200mm, 970*1900mm or customize

- Thickness: 0.15mm-1.5mm

- Moisture Content: <12%