Tongue and Groove Plywood

-

HW T&G Tongue And Groove CD Pine Plywood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-14pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Face/Back: CD Pine/custom

- Core: Poplar/Eucalyptus/Combi

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:5–30mm/custom

- Glue:Phenolic/Melamine/E0/E1/E2/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 520-700KGS/CBM

- Moisture Content: <12%

-

HW Tongue and Groove – 3/4 – Plywood

HW Tongue and Groove—3/4-inch Plywood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-14pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Face/Back: CD Pine/custom

- Core: Poplar/Eucalyptus/Combi

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:5–30mm/custom

- Glue:Phenolic/Melamine/E0/E1/E2/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 520-700KGS/CBM

- Moisture Content: <12%

-

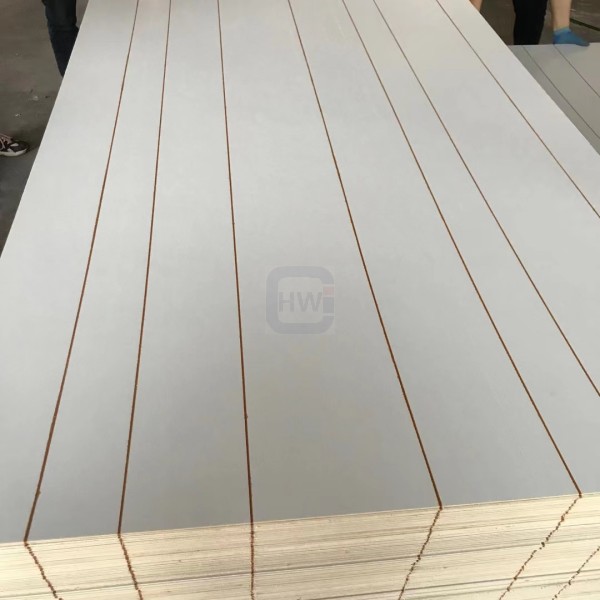

Melamine Paper Faced Slotted/Grooved Plywood

- Melamine Paper Faced Slotted/Grooved Plywood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Face/Back: Melamine Paper/custom

- Surface: Tongue and Groove

- Core: Poplar/Eucalyptus/Combi

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:3–30mm/custom

- Glue:E0/E1/E2/Custom

Tongue and Groove Plywood Introduction

Tongue and Groove Plywood is a type of plywood that is designed to interlock at the edges to create a tight, secure fit. The tongue and groove joint is made by pressing a tongue into a groove. The tongue fits into the groove to create a tight, snug fit between the two panels.

This type of plywood is commonly used in construction for flooring, subfloors, and roofing. The tongue and groove design helps to create a more stable and level surface. As the interlocking joints help to distribute weight evenly and prevent shifting.

The plywood is available in various thicknesses and grades. With different types of wood veneers and core materials, such as MDF or particleboard. It is important to select the appropriate grade and thickness for the intended use. As well as to properly install and fasten the panels to ensure a strong and durable finished product.

Feature

-

Interlocking joints: This plywood design allows the panels to interlock and create a tight fit. Which helps to prevent shifting and movement. This makes it ideal for flooring and subflooring applications.

-

Sturdy and stable: The interlocking joints also make the plywood more sturdy and stable. Which can help to reduce squeaks and creaks in floors.

-

Uniformity: This plywood has a uniform appearance. Which can help to create a more seamless and polished look in finished projects?

-

Versatility: It can be used for a variety of applications. Such as flooring, subfloors, roofing, and walls.

-

Strength: The plywood is strong and durable. Making it a reliable choice for construction projects.

-

Ease of installation: The tongue and groove design makes installation easier and quicker. As it allows the panels to fit together without the need for additional adhesives or fasteners.

-

Resistance to moisture: When properly sealed and finished, tongue and groove plywood can be resistant to moisture. Making it ideal for use in damp or humid environments.

FAQ

Q: What is the difference between tongue and groove plywood and regular plywood?

A: Plywood has interlocking joints, while regular plywood does not. The tongue and groove design helps to create a more stable and level surface. Which makes it ideal for flooring and subflooring applications.

Q: What types of wood veneers are used in tongue and groove plywood?

A: Plywood can be made with various types of wood veneers. Such as oak, pine, birch, and maple, among others. The choice of veneer depends on the intended use of the plywood.

Q: How thick should tongue and groove plywood be for flooring?

A: The thickness of tongue and groove plywood for flooring depends on the joist spacing and the expected load. For standard residential construction, 3/4-inch thick groove plywood are typically used.

Q: How is tongue and groove plywood installed?

A: Plywood is typically installed with a pneumatic flooring stapler or nailer. Which drives fasteners through the tongues and into the subfloor. The panels should be installed perpendicular to the floor joists for maximum stability.

Q: Can tongue and groove plywood be used for roofing?

A: Yes, plywood can be used for roofing applications. But it should be treated with a weather-resistant coating or finish to protect it from moisture and UV rays.