HW Tongue and Groove – 3/4 – Plywood

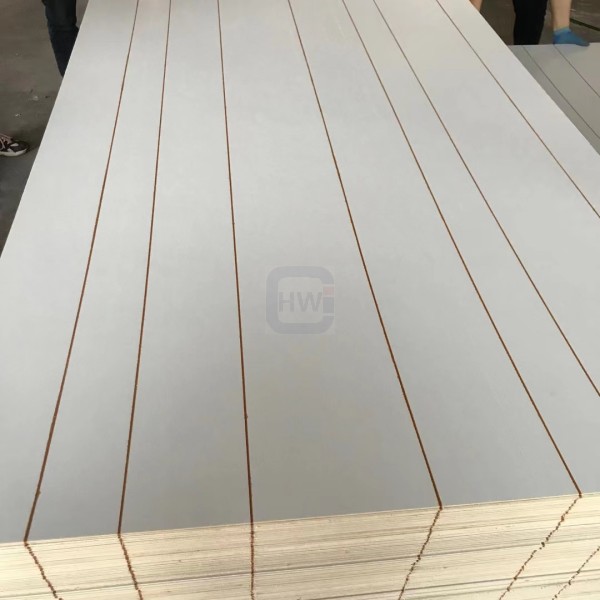

Tongue and groove plywood is a type of engineered wood paneling that features a unique interlocking system. The tongue is a ridge or protrusion on one edge of the board that fits into a corresponding groove or slot on the edge of another board. When the boards are joined together, they create a tight, seamless surface with no gaps or spaces between them.

The term “3/4” refers to the thickness of the plywood. In this case, the plywood is three-quarters of an inch thick. This is a standard thickness for many types of plywood, including tongue and groove panels.

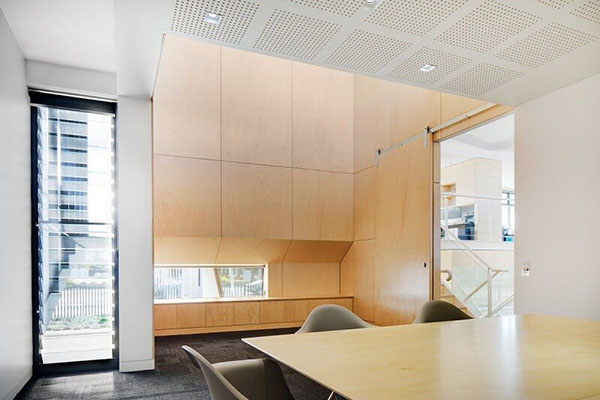

Tongue and groove plywood are often used in construction and home improvement projects where a strong, stable, and attractive surface is needed. It can be used for subflooring, roofing, wall paneling, and more. The interlocking design of the boards makes them particularly useful in areas where moisture or temperature changes may cause other types of wood paneling to warp or buckle.

HW Tongue and Groove—3/4-inch Plywood Feature

1. Interlocking Design: The tongue and groove design of the plywood provides a tight and seamless fit between the boards, creating a stable and secure surface.

2. Easy Installation: The interlocking design also makes installation easier and quicker, as there is no need for additional fasteners or adhesives.

3. Strength and Durability: The plywood’s multi-layered construction and interlocking design make it strong and resistant to warping or splitting.

4. Moisture Resistance: Tongue and groove plywood is often treated with moisture-resistant chemicals or coatings, making it ideal for use in damp or humid environments.

5. Versatility: The plywood can be used for a variety of applications, such as subflooring, roof decking, wall paneling, and more.

6. Aesthetics: The interlocking design of the plywood provides a clean and attractive surface that can be left natural or finished with paint, stain, or other coatings to match the desired look of the project.

Product Details

Brace Ply

different sheet sizes in 4mm/4.5 thick.

Brace ply is regularly used in applications such as the backing of cabinets, linings of a garage, and bracing in construction for

both load-bearing walls and roofs.

The plywood is sourced from resources that have been legally harvested and comply with AS2269 for the A-Bond Phenolic glue bond.

Specifications

Veneer Grades: “D” grade face “D” grade back

Stress Grades: F22

Dimensions: 2440mm x 900mm, 2745mm x 900mm, 3050mm x 900mm ,2440mm x 1200mm, 2745mm x 1200mm,3050mm x 1200mm

Thicknesses: 4mm/4.5mm

Glue Bond: A-Bond phenolic – 72-hour boil

Species: Selected Hardwoods

Density: 725 kg/m3 approx

Emissions: E0

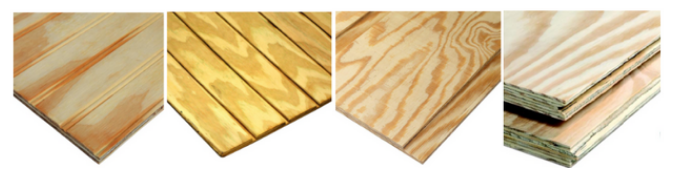

CD Structural Plywood

Pine structural plywood and Hardwood structural plywood are both manufactured to AS/NZ2269 using a phenolic “A” bond resin bonding

the individual timber veneers.

This exterior grade plywood has known and consistent structural performance and the design properties are published in the Timber

Structures Code AS1720.1 & are certified by the Engineered Wood Products Association of Australasia (EWPAA) as compliant for Structural Plywood.

Specifications – Hardwood

Veneer Grades: “C” grade face “D” grade back

Stress Grades: F11/ F14 / F17/ F22

Dimensions: 2400mm x 1200mm

Thicknesses: 7mm, 9, 12, 15, 17, 19, 21 & 25mm

Glue Bond: A-Bond Phenolic – 72-hour boil.

Species: Selected Hardwoods

Density: 725 kg/m3 approx

Preservative Treatment: H2 Glue Line Treated

Emissions: E0

Product Parameters

| Product Name | HW Tongue And Groove Plywood | ||

| Size | 1220x2440mm/1250x2500mm/ or as the client’s requirement | ||

| Thickness | 5-30mm | ||

| Thickness Tolerance | +/-0.2mm (thickness<6mm), +/-0.3~0.5mm (thickness≥6mm) | ||

| Face/Back | E-Wood, Okoume, Ilomba, Poplar, Birch, Bintangor, Hardwood, Pine, Pencil Cedar, Keruing, Agathis, Meranti, etc. | ||

| Core | Poplar, hardwood, eucalyptus, Okoume, birch, pine, combi, etc. | ||

| Joint Way of The Core | Overlap joint, end joint, scarf joint, or finger joint | ||

| Glue | E0, E1, E2, MR, Melamine or WBP | ||

| Grade | B/BB,BB/BB,BB/CC,DBB/CC; ect | ||

| Density | 520~700kg/m3 | ||

| Technical Parameters | Moisture Content | <12% | |

| Water Absorption | ≤10% | ||

| Modulus of Elasticity | ≥5000Mpa | ||

| Static Bending Strength | ≥30Mpa | ||

| Surface Bonding Strength | ≥1.60Mpa | ||

| Internal Bonding Strength | ≥0.90Mpa | ||

| Screw Holding Ability | Face | ≥1900N | |

| Edge | ≥1200N | ||

| Usage & Performance | Plywood is widely used for Automotive Interiors, furniture, decoration, construction, and packing. With good properties, such as easy fabricability, high bending strength, strong screw-holding ability, heat resistance, anti-static, long-lasting, and no seasonal effect. | ||

| MOQ | 1×20’FCL | ||

| Supply Ability | 5000cbm/month | ||

| Payment Terms | T/T or L/C at sight | ||

| Delivery Time | Within 20 days after receiving the deposit or original L/C at sight | ||

| Certification | CE, FSC, EUTR, CARB,EPA, JAS, ISO | ||

Details Images

Delivery Instructions

| Packing | Standard Export Pallet Packing | Inner Packing | The pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | The pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/50cbm | |||

Packaging and Containerization

Application

Commercial Plywood for Furniture, countertops, laminations, kitchens, and other interior work, as well as for other usages.

FAQ

Q: What is the difference between tongue and groove plywood and regular plywood?

A: Tongue and groove plywood has a unique interlocking design that allows the boards to fit tightly together, creating a seamless surface with no gaps or spaces. Regular plywood does not have this interlocking design.

Q: Can tongue and groove plywood be used for exterior applications?

A: Yes, tongue and groove plywood can be used for exterior applications if it is properly treated or coated to resist moisture and weathering.

Q: How is tongue and groove plywood installed?

A: Tongue and groove plywood is typically installed by fitting the boards together and then nailing or screwing them into place. Adhesive can also be used to secure the boards in place.

Q: Are tongue and groove plywood more expensive than regular plywood?

A: Tongue and groove plywood may be slightly more expensive than regular plywood due to its unique interlocking design, but it also offers additional benefits and advantages that may justify the added cost.

Q: Can tongue and groove plywood be used as a subfloor?

A: Yes, tongue and groove plywood is often used as a subfloor because of its strength and stability. It provides a reliable and level surface for flooring materials to be installed over.