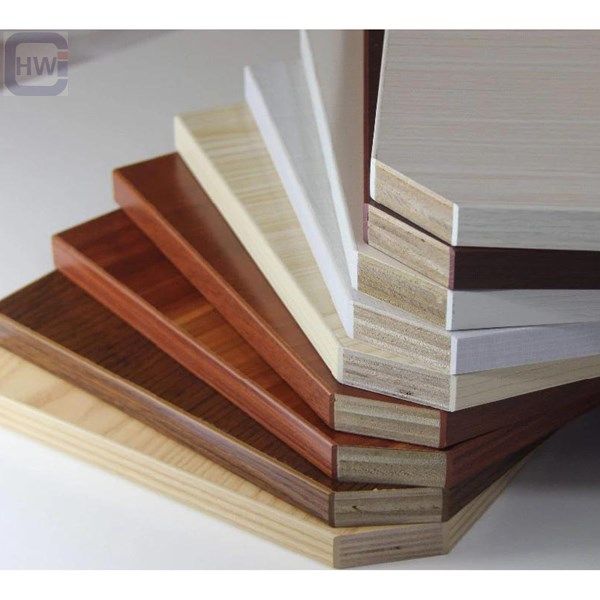

Laminated Board

-

HW High-Grade Melamine Faced Plywood

· Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

· Face/Back: Melamine Paper/custom

· Core: Poplar/Eucalyptus/Combi

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–30mm/custom

· Glue:E0/E1/E2/Custom

-

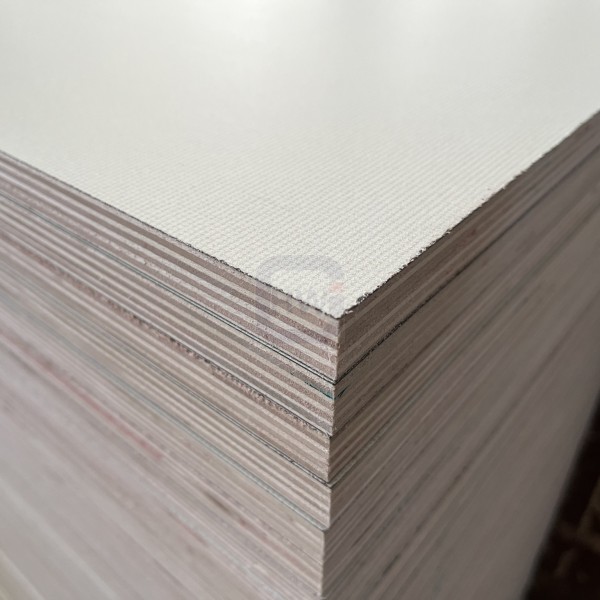

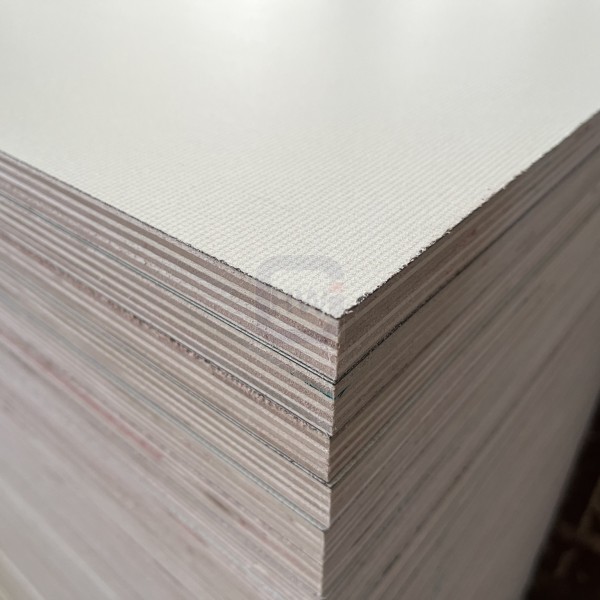

HW Luxury Design White Waterproof HPL Plywood Board

- HPL Surface Coated Plywood Board

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB, EPA, JAS, ISO

- Face/Back: HPL/custom

- Core: Poplar/Eucalyptus/Combi

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:3–18mm/custom

- Glue:E0/E1/E2/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 520-700KGS/CBM

- Moisture Content: <12%

-

HW Melamine Paper Commercial Plywood

· Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

· Face/Back: Melamine Paper/custom

· Core: Poplar/Eucalyptus/Combi

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–30mm/custom

· Glue:E0/E1/E2/Custom

-

Kitchen Cabinet HPL Plywood

Kitchen Cabinet HPL Plywood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB, EPA, JAS, ISO

- Face/Back: HPL/custom

- Core: Poplar/Eucalyptus/Birch/Combi

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:3–30mm/custom

- Glue:E0/E1/E2/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 520-700KGS/CBM

- Moisture Content: <12%

-

Kitchen Cabinet HPL Plywood For Sale

Kitchen Cabinet HPL Plywood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB, EPA, JAS, ISO

- Face/Back: HPL/custom

- Core: Poplar/Eucalyptus/Birch/Combi

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:3–30mm/custom

- Glue:E0/E1/E2/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 520-700KGS/CBM

- Moisture Content: <12%

-

Lightweight Furniture Plywood Panels For Sale

Lightweight Furniture Plywood Panels – Lightweight HPL Laminated Plywood

We produces lightweight furniture boards based on a plywood core. The panels look good, cut and machine cleanly with no break-out, are impact resistant, and do not add excess weight.

Morland can offer over two thousand different laminate surfaces applied to poplar plywood to create a lightweight furniture board. Any of these can be bonded to one side or both.

-

Melamine Paper Plywood

Melamine Paper Plywood

· Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

· Face/Back: Melamine Paper/custom

· Core: Poplar/Eucalyptus/Combi

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–30mm/custom

· Glue:E0/E1/E2/Custom

-

Natural Wood Veneered Fancy Plywood

Natural Wood Veneered Fancy Plywood

Fancy plywood, also called decorative plywood, is usually veneered with good-looking hardwood veneers, such as red oak, ash, white oak, birch, maple, teak, sapele, cherry, beech, walnut and so on.

Red oak ( grade: AAA/AAA, BB/BB, A/B, B/C, c/c) fancy plywood, natural ash, red beech, white oak (Q/C), red beech, bubinga, sapele (C/C), natural teak(C/C), ect.

Red oak (c/c) fancy plywood, natural ash, red beech, white oak (Q/C), red beech, bubinga, sapele (C/C), natural teak(C/C), ect.

-

Natural Wood Veneered Fancy Plywood For Sale

Natural Wood Veneered Fancy Plywood

Fancy plywood, also called decorative plywood, is usually veneered with good-looking hardwood veneers, such as red oak, ash, white oak, birch, maple, teak, sapele, cherry, beech, walnut and so on.

Red oak ( grade: AAA/AAA, BB/BB, A/B, B/C, c/c) fancy plywood, natural ash, red beech, white oak (Q/C), red beech, bubinga, sapele (C/C), natural teak(C/C), ect.

Red oak (c/c) fancy plywood, natural ash, red beech, white oak (Q/C), red beech, bubinga, sapele (C/C), natural teak(C/C), ect.

-

Red Oak Plywood

- Red Oak Plywood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Surface: red oak, ash, white oak, birch, maple, teak, sapele , cherry, beech, walnut and so on

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:3–30mm/custom

- Glue:E0/E1/E2/Custom

-

Red Oak Plywood For Sale

- Red Oak Plywood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Surface: red oak, ash, white oak, birch, maple, teak, sapele , cherry, beech, walnut and so on

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:3–30mm/custom

- Glue:E0/E1/E2/Custom

-

Veneer Fancy Plywood– Decorative Veneer Plywood

Veneer Fancy Plywood – Decorative Veneer Plywood

Fancy plywood, also called decorative plywood, is usually veneered with good-looking hardwood veneers, such as red oak, ash, white oak, birch, maple, teak, sapele, cherry, beech, walnut and so on.

Red oak ( grade: AAA/AAA, BB/BB, A/B, B/C, c/c) fancy plywood, natural ash, red beech, white oak (Q/C), red beech, bubinga, sapele (C/C), natural teak(C/C), ect.

Red oak (c/c) fancy plywood, natural ash, red beech, white oak (Q/C), red beech, bubinga, sapele (C/C), natural teak(C/C), ect.

Laminated Board Introduction

A laminated board, also known as laminated wood, is a type of engineered wood that is made by layering thin sheets of wood veneer or other materials together using adhesive. The resulting board is stronger and more durable than natural wood and can be used for a wide range of applications. Including furniture, cabinetry, flooring, and decorative panels. The process of making this type of board involves bonding layers of wood veneer or other materials. Such as particleboard or MDF (medium-density fiberboard), together with the help of an adhesive. The adhesive used can be made from a variety of materials. Such as phenol-formaldehyde, urea formaldehyde, or melamine. The laminated board comes in a variety of thicknesses, sizes, and grades, and can be made from different types of wood. Such as pine, birch, or oak. It is also available in different finishes. Such as smooth, textured, or glossy. One of the main benefits of this board is its strength and durability, which make it ideal for use in high-traffic areas or where moisture and humidity are a concern. It is also resistant to warping, cracking, and splitting. Which makes it a popular choice for outdoor furniture and construction applications. Overall, the board is a versatile and reliable material that offers many benefits over natural wood and is widely used in a variety of industries and applications.Laminated Board Feature

- Strength and Durability: It is stronger and more durable than natural wood, making it ideal for use in high-traffic areas and where moisture or humidity is concerned. It is also resistant to warping, cracking, and splitting. Which makes it a popular choice for outdoor furniture and construction applications.

- Versatility: This board comes in a variety of thicknesses, sizes, and grades, and can be made from different types of wood or other materials. It is also available in different finishes. Such as smooth, textured, or glossy.

- Consistency: Because the laminated board is manufactured. It has a consistent quality and appearance. Making it easier to work with and ensuring that the final product looks and performs as intended.

- Cost-Effective: The board is typically less expensive than solid wood. Making it a cost-effective alternative for many applications.

- Sustainability: This type of board is made from renewable materials and can be recycled or reused. making it a sustainable choice for environmentally conscious consumers.