Red Oak Plywood

Product Details of Red Oak Plywood:

The leading supplier of hardwood veneer faced panels in China

a fancy veneer is defined as “a thin sheet of wood, rotary cut, sliced, or sawed from a log, bolt or flitch.”

Kinds of fancy veneer like Birch, red oak, maple, ash, poplar, cherry, and other species are supplied throughout the decorative plywood, furniture, cabinetry, door, and profile-wrap industries.

Raw Material – Veneer

Veneer Grades

Select Veneer is composed entirely of heartwood or sapwood and is matched for both grain, pattern, and color.

Uniform Veneer is also composed of entirely heartwood or sapwood but is matched for color only.

Natural Veneer is composed of both heartwood and sapwood and is generally less expensive than select or uniform veneers.

Paint Grade Veneer has a smooth enough finish so none of the wood grain characteristics show through the paint.

Stain Grade Veneer is meant to take a clear or tinted stain and still show the natural characteristics of the wood.

Natural Veneer – Red Oak / White Oak / Sapele / Beech / Okoume / Burma Teak / Recon

Substrate – Particle Board / MDF / Plywood/Blockboard

Red Oak Plywood Feature

1. Durability: Red Oak Plywood is a strong and durable material that can withstand wear and tear. It is less prone to warping, splitting, or cracking compared to solid wood.

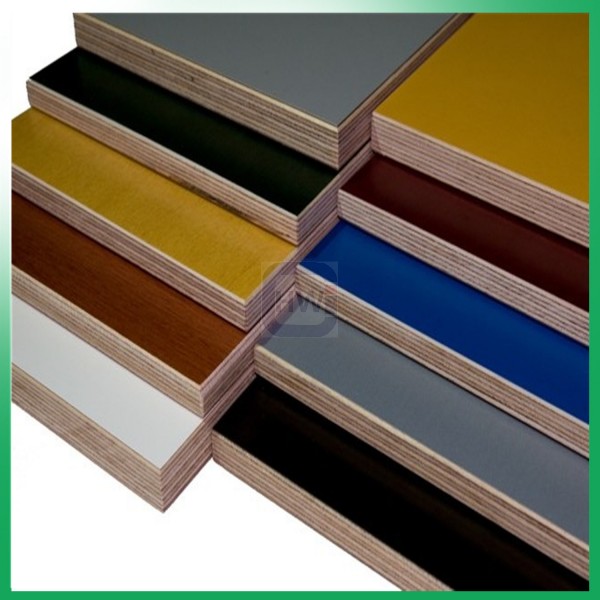

2. Aesthetic appeal: Red Oak Plywood has a beautiful, distinct grain pattern that adds an elegant look to any project. It is also available in different finishes, such as clear, stain, or paint, which makes it versatile and adaptable to different design styles.

3. Workability: Red Oak Plywood is relatively easy to work with using common woodworking tools, such as saws, routers, and sanders. It also holds nails and screws well, making it a good choice for furniture, cabinetry, and other woodworking projects.

4. Availability: Red Oak Plywood is widely available in different grades and thicknesses, making it a convenient material to source for woodworking projects. It can be found at most lumberyards, home improvement stores, and online retailers.

Surface Species of Plywood:

Delivery Instructions of Red Oak Plywood:

| Packing | Standard Export Pallet Packing | Inner Packing | The pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | The pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/50cbm | |||

Packaging and Containerization

Application of Red Oak Plywood:

Fancy veneer-coated Plywood MDF board for Furniture, laminations, kitchens, and other interior work, as well as for other usages.

FAQ

Q: What is Red Oak Plywood used for?

A: Red Oak Plywood is used for a variety of woodworking projects, including furniture, cabinetry, paneling, and flooring. It is also commonly used for sheathing, subflooring, and other structural applications.

Q: Is Red Oak Plywood waterproof?

A: No, Red Oak Plywood is not waterproof. While it is a durable and strong material, it can still be damaged by prolonged exposure to water or moisture. It is important to use a sealant or finish to protect Red Oak Plywood from water damage.

Q: How is Red Oak Plywood made?

A: Red Oak Plywood is made by gluing thin layers of red oak wood veneer together, with the grain direction alternating between each layer. The layers are stacked and pressed together under heat and pressure to create a strong, stable sheet of plywood.

Q: What are the different grades of Red Oak Plywood?

A: Red Oak Plywood is available in different grades, ranging from cabinet grade to utility grade. Cabinet grade Red Oak Plywood has a smooth surface and is used for high-end furniture and cabinetry. Utility-grade Red Oak Plywood has a rough surface and is often used for sheathing, subflooring, and other structural applications.

Q: Can Red Oak Plywood be stained or painted?

A: Yes, Red Oak Plywood can be stained or painted to match different design styles. It is important to prepare the surface of the plywood properly before applying a stain or paint to ensure good adhesion and a smooth finish.