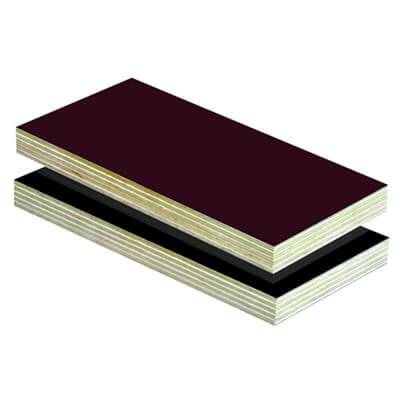

Film Faced Plywood

-

Black Film-Faced Plywood

Film Faced Plywood is also called Formwork Plywood, Shuttering Plywood, Concrete formwork. Film faced plywood is the special plywood with two sides coated with wearable and water proof film. The film is adhesive impregnated paper, which are different from melamine paper overlay, PVC, MDO and HDO. The function of the film is to protect the inside wood from moisture, water, weather and extend the plywood’s service life. Film Faced Plywood is an exterior plywood used in building and construction projects……

-

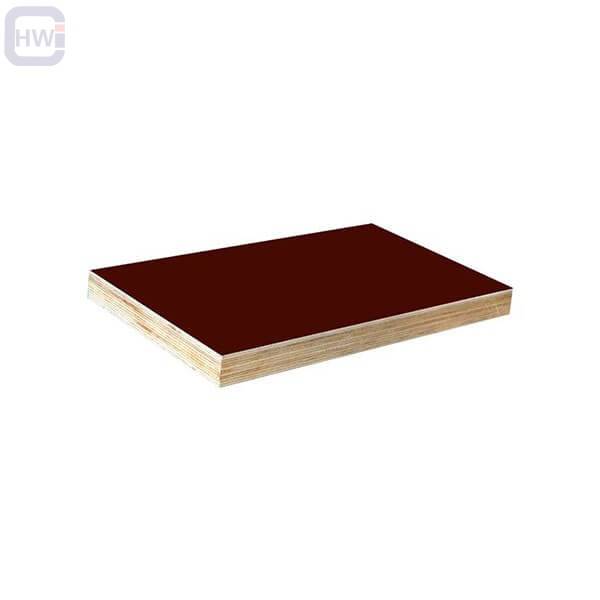

Brown Film Faced Plywood

Film Faced Plywood is also called Formwork Plywood, Shuttering Plywood, or Concrete formwork. Film-faced plywood is a special plywood with two sides coated with a wearable and waterproof film. The film is adhesive-impregnated paper, which is different from melamine paper overlay, PVC, MDO, and HDO. The function of the film is to protect the inside wood from moisture, water, and weather and extend the plywood’s service life. Film Faced Plywood is exterior plywood used in building and construction projects……

-

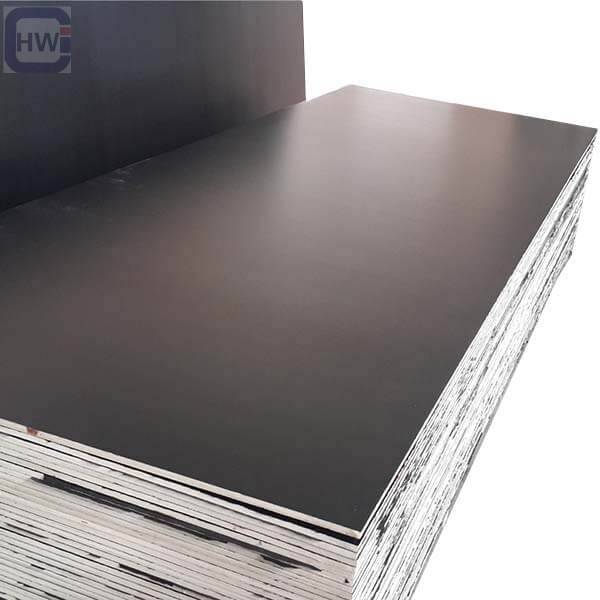

HW Black Oversize Film-Faced Plywood

Film Faced Plywood is also called Formwork Plywood, Shuttering Plywood, or Concrete formwork. Film-faced plywood is a special plywood with two sides coated with a wearable and waterproof film. The film is adhesive-impregnated paper, which is different from melamine paper overlay, PVC, MDO, and HDO. The function of the film is to protect the inside wood from moisture, water, and weather and extend the plywood’s service life. Film Faced Plywood is exterior plywood used in building and construction projects……

-

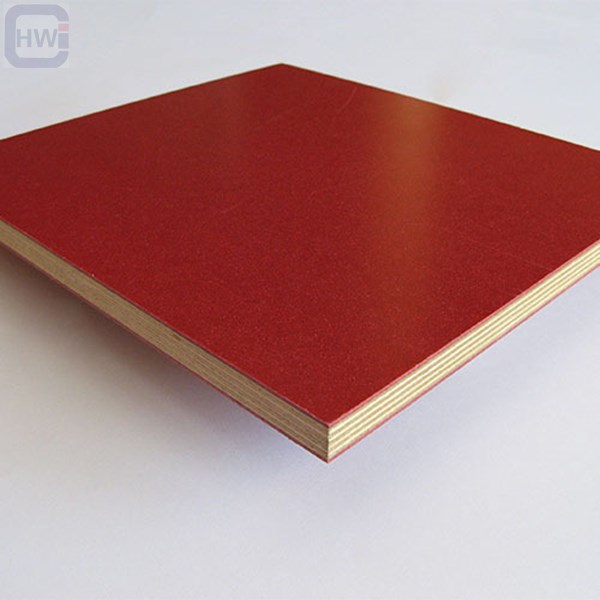

Red Film Faced Plywood

Material and Composition: Red Film Faced Plywood is made from layers of wood veneers bonded together with a strong adhesive. The distinctive feature of this plywood is its red-colored film coating on one or both sides. This film is typically made from a phenolic resin, which imparts strength and durability to the plywood.- Durability and Moisture Resistance: This type of plywood is highly durable and resistant to moisture, thanks to its resin-coated surface. The film facing acts as a barrier against water and humidity, making it an ideal choice for outdoor and construction applications where exposure to the elements is a concern.

- Appearance and Finish: The red film coating not only provides protection but also gives the plywood a smooth and uniform surface. This makes it ideal for applications where a consistent and aesthetic appearance is desired. The red color also makes it easily identifiable on construction sites.

- Strength and Stability: Red Film Faced Plywood is known for its high strength and stability. The cross-grained structure of the plywood distributes the load evenly, enhancing its load-bearing capacity. This makes it suitable for use in demanding applications such as formwork in concrete construction.

- Applications: This plywood is commonly used in the construction industry, especially for making concrete formwork, scaffolding, hoardings, and outdoor furniture. Its ability to withstand harsh conditions and repeated use makes it a cost-effective and reliable choice for builders and contractors.

Film-Faced Plywood Introduction

Film-faced plywood is a type of plywood that has a film or a paper coating applied to both sides of the plywood sheet. The film or paper coating is typically made of phenolic resin, which makes the plywood resistant to water, wear, and tear. The film or paper coating also gives the plywood a smooth and consistent surface that is ideal for various applications. Plywood is commonly used in construction and building projects, especially for concrete formwork. The smooth and durable surface of the plywood allows for easy removal of the concrete after it has been set. The phenolic resin coating also makes the plywood resistant to moisture, which is important in construction applications where water exposure is a concern. Other applications of film-faced plywood include its use in the transportation industry. Such as for truck and trailer flooring, and in the manufacturing of furniture and packaging materials. The thickness of film-faced plywood can vary depending on the intended use, with thinner sheets used for decorative purposes and thicker sheets used for heavy-duty applications.Film-Faced Plywood Feature

- Water Resistance: The phenolic resin coating on the plywood makes it highly resistant to water and moisture. This makes it ideal for use in applications where water exposure is a concern.

- Durability: It is known for its durability and resistance to wear and tear. The smooth and consistent surface of the plywood makes it ideal for use in construction projects, especially for concrete formwork.

- Strength: The plywood is made from multiple layers of wood, which gives it high strength and stability. This makes it a reliable choice for applications where strength is a priority.

- Easy to Clean: The smooth surface of the plywood makes it easy to clean and maintain. This is particularly useful in applications where cleanliness is a priority, such as in the food industry.

- Versatility: This kind of plywood can be used in a wide range of applications, from construction to furniture manufacturing to packaging. This makes it a versatile and cost-effective choice for many different industries.