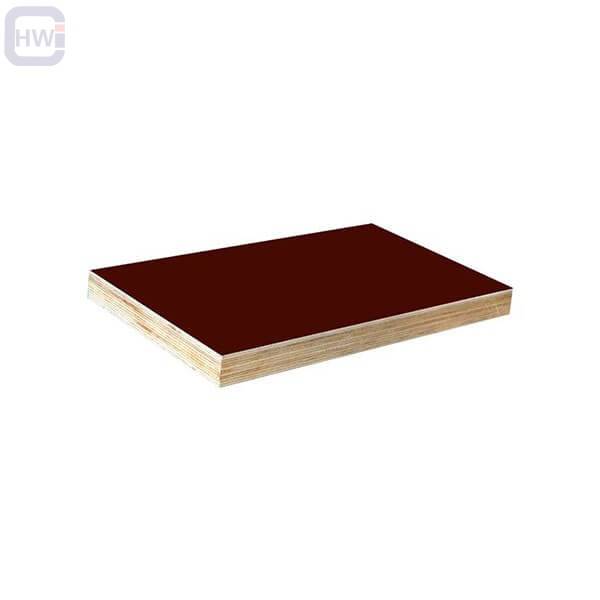

Brown Film Faced Plywood

Film-faced plywood is lightweight, resistant to corrosion attack and water, easily combined with other materials, and easy to clean and cut. Treating the film-faced plywood’s edges with waterproof paint makes it highly water-and wear-resistant. Due to its durability and easily handled surface, it can be used in an open environment in construction and building.

Coating the film-faced plywood with high-quality imported films ensures hardness and damage resistance.

The surface of the film-faced plywood is hygienic and resistant to strong detergents.

It can be used in conditions of high-temperature drop, the influence of moisture, detergent cleaning, and provides protection against termites.

We offer two types of film-faced plywood. The first is birch film-faced plywood which is very resistant to water, easy to clean and cut, and one of the world’s best quality plywood. The second is poplar film-faced plywood. This plywood type is also easy to clean and cut and is a softer and lighter material than birch film-faced plywood.

Brown Film Faced Plywood Feature

1. Water resistance: The phenolic film coating on both sides of the plywood provides excellent water resistance, making it suitable for use in wet and humid environments.

2. Durability: The film-faced plywood is highly durable and resistant to wear and tear, making it ideal for use in construction and building projects.

3. Strength: The plywood is made from high-quality hardwood or softwood veneers that are bonded together with an adhesive, making it strong and stable.

4. Chemical resistance: The phenolic film coating is highly resistant to chemicals, making it suitable for use in industrial and chemical environments.

5. Easy to work with: The film-faced plywood is easy to cut, drill, and shape, making it convenient for use in various construction applications.

6. Cost-effective: Brown film-faced plywood is relatively affordable compared to other building materials, making it a cost-effective option for construction projects.

7. Versatility: The plywood can be used for a wide range of applications, including concrete formwork, flooring, walls, and roofs.

Specification of Film-Faced Plywood:

1). Film color:

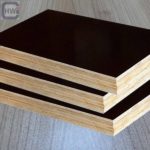

Red, Brown, Black, or others

The most common film is a brown film or a black film. In China, brown film-faced plywood usually has better quality than black film-faced plywood. However, it’s not true all the time. Some black film-faced plywood has the same high quality as brown film-faced plywood. When you make an inquiry, an experienced salesman will know what the real quality you need is.

2). Quality of Film :

In China, there are 2 classifications of film: Local film and imported film. The local film means films made by Chinese companies. An imported film means a film made by foreign companies, like Dynea. Dynea Film is the best film brand in China. So if you require the best film for your plywood, we will use Dynea film.

3). Core:

Poplar, Hardwood, Eucalyptus, Birch

70% of the film-faced plywood we are selling is poplar film-faced plywood, which is high quality and price competitive. If you need hardwood film-faced plywood, we will use hardwood or eucalyptus veneers. If you want film-faced plywood for building bridges or high buildings, you can choose hardwood film-faced plywood, as its name says, it’s very hard. We also supply birch film-faced plywood, which is hard and durable, too.

4). Glue:

Phenolic-WBP; Melamine-WBP; MR

5). Size:

1220X2440mm, 1250X2500mm, or 4′ x 8′, standard size, large size, big size, special size

We produce sizes according to customers’ requirements. The widest size can be 2000mm, max length is 6000mm.

6). Thickness:

4mm-30mm (4mm / 6mm / 9mm / 12mm / 15mm / 18mm / 21mm-50mm )

We supply very thin film-faced plywood of 4mm and the thickest plywood of up to 50mm. This is our advantage.

7) Edge:

Sealed by water-proof paint

8) Usage :

Construction formwork panel/ Stairs/car trailers/ Container floor and wall/automotive engineering floor and side walls and

other special applications etc.

9 ) Mark:

It also enjoys the same properties as film-faced plywood in regards to moisture resistance/proof (depending on the bonding glue type).

Contact us if you need more info.

Delivery Instructions of Film-Faced Plywood:

| Packing | Standard Export Pallet Packing | Inner Packing | The pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | The pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/50cbm | |||

Packaging and Containerization of Film-Faced Plywood:

Application of Film-Faced Plywood:

Film-faced plywood can also be used to build sliding doors, advertising boards, playground equipment, floors for sports arenas, smooth concrete casts, scaffolding, hoardings and fencings, packing, and in internal & external design and paneling.

- Construction industry: Shuttering Film Faced Plywood, Concrete Formwork, Shuttering Concrete Formwork, Formwork Plywood

Film-faced plywood is mainly used for construction. So film-faced plywood is also called shuttering film-faced plywood, concrete form, or shuttering concrete form. Because of this end use, customers usually want WBP film-faced plywood, which is more suitable to be used as shuttering for big projects. However, some customers require MR film-faced plywood, which is to be used as shuttering for ordinary projects.

- Anti-Slip Film Faced Plywood: flooring materials for building vehicles, and work platforms.

According to the types of face/back, film-faced plywood can be divided into smooth film-faced plywood and anti-slip film-faced plywood. Anti-slip film-faced plywood is usually used as the flooring material for vehicles, trucks, and platforms.

- Film-faced plywood can be used for shelves and furniture, too.

Compared with wood veneer-faced plywood, film-faced plywood is more durable and has more wear-resistant surfaces. So it can be used for making durable furniture and shelves.

FAQ

Q: What is brown film-faced plywood used for?

A: Brown film-faced plywood is mainly used in construction and building projects for concrete formwork, flooring, walls, and roofs. It can also be used in industrial and chemical environments due to its chemical resistance.

Q: What are the standard sizes and thicknesses of brown film-faced plywood?

A: The standard size of brown film-faced plywood is 1220mm x 2440mm, and the thickness ranges from 9mm to 18mm. However, the thickness and size can be customized to suit specific requirements.

Q: What is the difference between brown film-faced plywood and black film-faced plywood?

A: The only difference is the color of the phenolic film coating. Brown film-faced plywood has a brown film coating, while black film-faced plywood has a black film coating. Both types of film-faced plywood offer similar features and are suitable for use in construction and building projects.

Q: Is brown film-faced plywood waterproof?

A: The phenolic film coating on both sides of the plywood provides excellent water resistance, making it suitable for use in wet and humid environments. However, it is important to note that the edges of the plywood are not water-resistant, and therefore, they need to be sealed with a waterproof sealant.

Q: How is brown film-faced plywood installed?

A: Brown film-faced plywood can be installed using screws, nails, or adhesive. The method of installation will depend on the specific application and the type of surface to which the plywood will be attached.