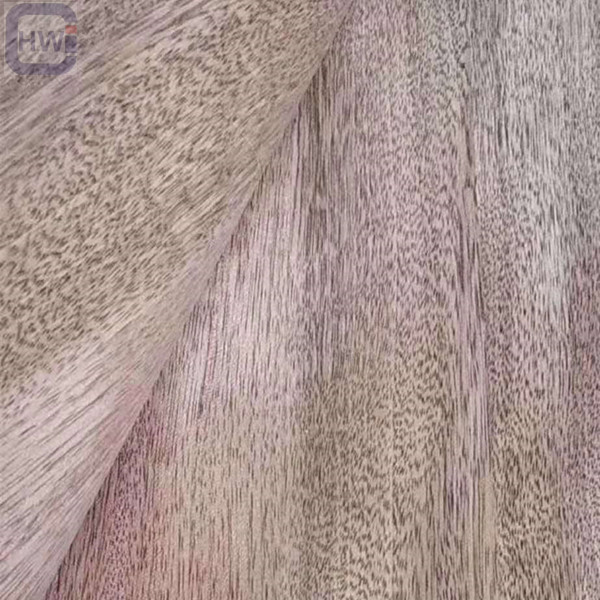

Red Face Veneer Decorative Natural Wood

The red face veneer is a type of decorative natural wood veneer that has a reddish hue. It is created by slicing a thin layer of wood from the surface of a tree trunk or branch and then applying it to a substrate material such as plywood or particleboard. The red color in red face veneer can be found in a variety of tree species, including cherry, mahogany, and maple.

The red face veneer is often used in furniture making, cabinetry, and interior design projects to add warmth and texture to a space. It can be used as a decorative accent or as a primary material for a larger surface area. The natural variation in color and grain pattern in red face veneer can make each piece unique and add character to a project.

It is important to note that, like all wood veneers, a red-face veneer is susceptible to changes in moisture and temperature, and proper care and maintenance are necessary to ensure its longevity.

Red Face Veneer Decorative Natural Wood Feature

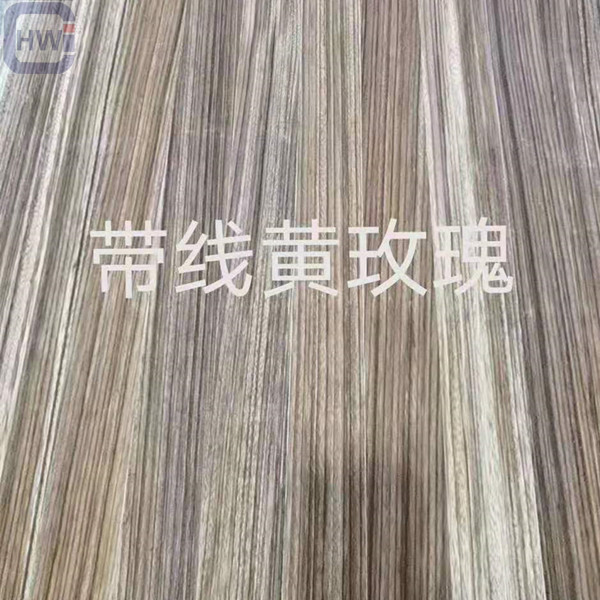

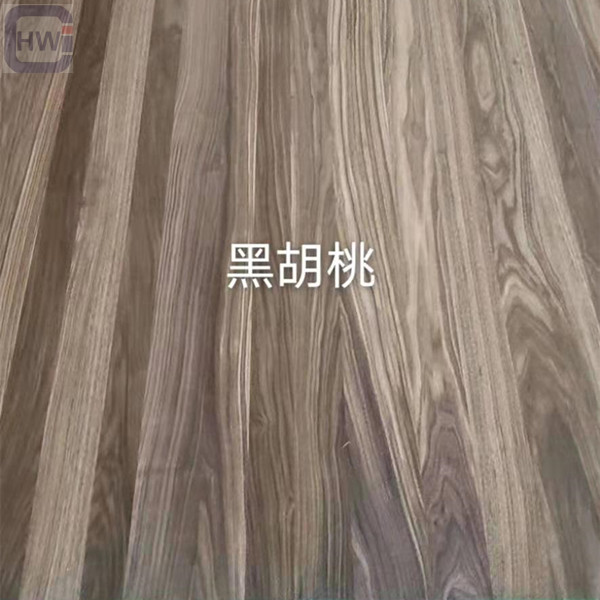

1. Color: Red face veneer has a distinct reddish color that adds warmth and richness to any space. The shade of red can vary depending on the type of wood species used, which can include cherry, mahogany, and maple.

2. Grain pattern: Each piece of red face veneer has a unique grain pattern, giving it a natural and organic look. This variation in grain pattern can add visual interest to furniture and interior surfaces.

3. Texture: The natural texture of the wood can be felt and seen in red face veneer, which can add depth and dimension to furniture and interior surfaces.

4. Durability: When properly cared for, a red-face veneer can last for many years. It is important to note that, like all wood veneers, it is susceptible to changes in moisture and temperature, so proper care and maintenance are necessary to ensure its longevity.

5. Versatility: Red face veneer can be used in a variety of interior design and furniture-making projects. It can be applied to surfaces such as cabinetry, furniture, and walls to add warmth and character to a space. It can also be used as an accent to add texture and interest to a room.

Parameters

| VENEER TYPE | THICKNESS | SIZE | LOADING | DELIVERY | |||

| OKOUME | 0.2/0.25/0.3/0.4/0.55/0.6/0.7MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| PENCIL CEDAR | 0.2/0.25/0.3/0.4/0.45MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| PLB | 0.25/0.3MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| BINTANGOR | 0.2/0.25/0.3/0.4/0.45/0.5MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| PINE | 0.5/0.6/0.7/0.8MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| EV | 0.2-1.5MM | 4X8(1280X2560MM) | 40HC | 15-25DAYS | |||

| Grade | A, B, C, D | ||||||

| Specification | Grade A: No discolor, No fiber, No hole, No splits Grade B: Slight discolor, small crack, No hole, No fiber Grade C: Medium discolor, Slight pin, bean hole, Light fiber Grade D: Discolor, splits, egg-size holes no more than 3 |

||||||

|

Moisture |

8-12% | ||||||

| Lead time | 10-25days after the deposit received | ||||||

| Shipping terms: | FOB, CNF, CIF | ||||||

| Package: | Standard Seaworthy packing | ||||||

| Inner Packing: The pallet is wrapped with a 0.20mm plastic paper | |||||||

| Outer Packing: The pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||||||

| Also, 6*3 metal belt | |||||||

| products samples | For free samples, need to pay the delivery fees by 1-2 days for ready samples, customized for 15 days. |

| After-sales services | After receiving goods, if any quality problem, take photos and send them to us. Then provide you free boards to replace in the next order after checking. |

| Product customization | no strict requirement about the size, but the tailored way should be basic on the basic material’ size. |

Product Show

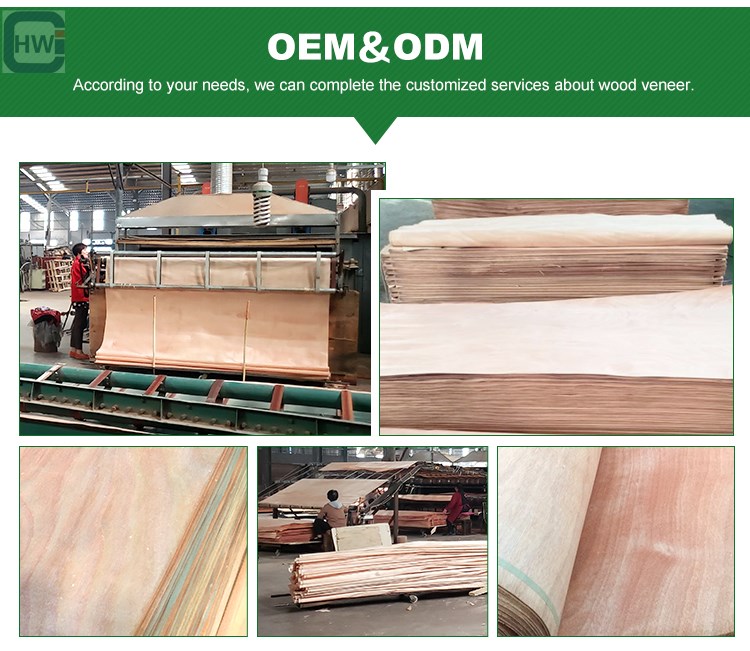

About the company

1. HW Group is your plywood manufacturer in China which can produce customized products with professional technology.

2. OUR MISSION is endless innovation, providing customers with high-quality products and services.

3. CERTIFICATION: CE, ISO, FSC, ASNZS, CARB/EPA

4. MAIN PRODUCTS: Thin Plywood, Furniture Grade plywood, Commercial Plywood, Film faced plywood, Fancy Plywood, LVL, and so on

5. CAPACITY Factory was established in 2002, located in Pizhou City, Jiangsu Province, covering

30,000 square meters, has 200 workers with 50.000CBM/year capacity, exports 1000 containers per year

6. ADVANTAGE 1)Professionalmanufacture technology and strong global resource meet your variety of demands. 2)Perfect and independent inspection system 3)Owner equips very fluent spoken English will further promote strategic partnership building between the two sides. 4)Honest and trustworthy. Responsible until after-sales.

7. MAIN MARKET Europe, America, Australia, Middle East, Asia, and Africa.

8. SERVICE HW has a sales team, docs team, quality inspection team, and logistics team

Mark:

Application

Wood veneer would be widely used as door inserts, floor, wall panels, ceiling panels, privacy screens, architectural millwork, and

furniture inlays, hotels, shopping malls, restaurants, lounges, commercial spaces, chains, offices, expos, columns, furniture, slide door,

interior door, house, bar, etc.

FAQ

Q: What is the difference between natural wood and wood veneer?

A: Natural wood is solid wood cut from the trunk of a tree, whereas wood veneer is a thin layer of wood that is sliced from the surface of a log and then applied to a substrate material such as plywood or particleboard.

Q: How is red face veneer made?

A: Red face veneer is made by slicing a thin layer of wood from the surface of a tree trunk or branch and then applying it to a substrate material using adhesive.

Q: What types of wood species are used for red-face veneer?

A: Cherry, mahogany, and maple are common wood species used for red face veneer.

Q: Can red face veneer be stained or painted?

A: Yes, red face veneer can be stained or painted to achieve a desired color or finish.

Q: How is red face veneer maintained?

A: Red face veneer should be cleaned regularly with a soft, dry cloth to remove dust and debris. Avoid using harsh chemicals or abrasive cleaners that could damage the wood. It is also important to protect red face veneer from moisture and extreme temperatures to prevent warping or cracking.