HW Australia Pine LVL Scaffolding Plank

Laminated Veneer Lumber (LVL) is a popular engineered wood product that is often used in construction and scaffolding applications. HW Australia Pine LVL Scaffolding Planks are made from layers of thin wood veneers that are bonded together with adhesive to create a strong, durable, and stable product that is resistant to warping, splitting, and twisting. These planks are commonly used in the construction of scaffolding platforms and walkways, as they can support heavy loads and provide a stable surface for workers to stand on. It is important to ensure that any scaffolding planks you use meet safety regulations and standards, and are regularly inspected and maintained to ensure their continued safety and reliability.

Short Description of HW Australia Pine LVL Scaffolding Plank

LVL-engineered wood planks

LVL (Laminated Veneer Lumber) is a new construction material. It can be customized to create high-value products for residential, commercial, formwork, and scaffolding applications.

Construction Grade LVL (laminated veneer lumber)

Parameters of HW Australia Pine LVL Scaffolding Plank

| Raw material | New Zealand radiate pine and Russia Larch |

| Size | T( 38/42) * W( 225/230) *L( 1000/1500/2500/3000/3900/6000-12000)mm |

| Glue | WBP glue with 72 hours of hot water boiling, Melamine glue with 8 hours of hot water boiling |

| Density | 560-660kgs/cbm |

| MC | 8-12% |

| Certificate | CE/ SGS/AS4357/FSC/ISO |

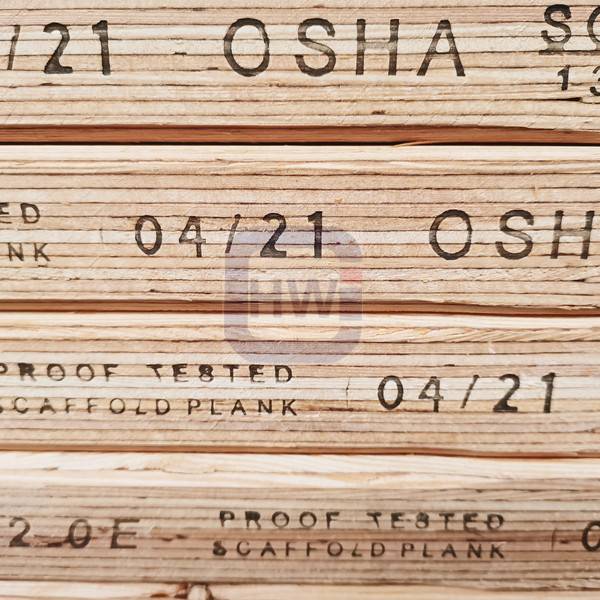

| Standard | OSHA middle duty, AS1577 heavy duty |

| End | Painting, or with metal cab |

Features & Advantages of Australia LVL Scaffold Plank:

1. Strength and durability: LVL is a strong and durable material that can support heavy loads and resist warping, splitting, and twisting.

2. Consistency: LVL is manufactured to precise specifications, ensuring consistent quality and performance.

3. Stability: LVL is less prone to shrinkage and expansion than solid wood, making it a stable material that can maintain its shape and dimensions over time.

4. Lightweight: LVL is lighter than many other types of wood, making it easier to handle and transport on construction sites.

5. Versatility: LVL can be easily cut and shaped to suit a range of construction and scaffolding applications.

Trade Terms of HW Australia Pine LVL Scaffolding Plank

1. OQ:1*40’HQ

2. Payment terms: T/T with a 30% deposit in advance or L/C at sight

3. Delivery time: 15~20 days after getting your deposit

4. Packing: Standard export packing, pallet with metal strips

5. FOB (Free on Board): The seller is responsible for loading the goods onto the shipping vessel at the port of origin, and the buyer is responsible for shipping and unloading the goods at the destination port.

6. CIF (Cost, Insurance, and Freight): The seller is responsible for shipping and insuring the goods to the destination port, while the buyer is responsible for unloading the goods.

7. EXW (Ex Works): The buyer is responsible for picking up the goods from the seller’s warehouse or factory and for all associated transportation and logistics costs.

8. DDP (Delivered Duty Paid): The seller is responsible for shipping the goods to the buyer’s destination, including all associated taxes and duties.

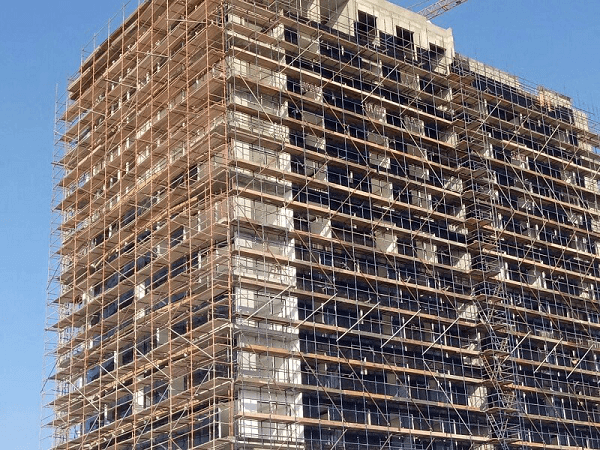

Pine LVL Scaffolding Plank is used for Construction, Formwork Systems, Bridge engineering, oil field engineering, etc.

Properties of LVL Scaffolding plank

1. Enhanced durability and safety (OSHA)

2. Unrivalled structural rigidity, stability, and strength

3. Proven to at least twice as long as solid wood equivalents

4.10% lighter than solid wood equivalents

5.No metal end band required

6.No ongoing maintenance or remedial repairs required

7. Excellent electrical insulation properties

8. Excellent anti-corrosive and chemical properties

Applications & comments of HW Australia Pine LVL Scaffolding Plank:

Used in place of metal scaffold boards or conventional timber. LVL Scaffold planks are affordable, tough, and long-lasting, especially in corrosive environments. Wax emulsion end sealing reduces moisture ingress. The timber is sourced from FSC-certified plantations which means that it is sustainable. LVL Scaffold planks are durable and have extremely long lifespans, they are also light and easy to handle.

Pine LVL Scaffolding Plank is used for Construction, Formwork Systems, Bridge engineering, oil field engineering, etc.

Packaging and Containerization of HW Australia Pine LVL Scaffolding Plank

FAQ

Q: What is the maximum load capacity of HW Australia Pine LVL Scaffolding Planks?

A: The load capacity of LVL planks depends on their dimensions and the specific application they are being used for. It is important to consult the manufacturer’s specifications and guidelines to ensure safe and appropriate use.

Q: Are HW Australia Pine LVL Scaffolding Planks waterproof?

A: While LVL is more resistant to water damage than solid wood, it is not completely waterproof. It is important to protect LVL planks from exposure to water and moisture, as prolonged exposure can cause warping and damage.

Q: Can HW Australia Pine LVL Scaffolding Planks be used in outdoor applications?

A: Yes, LVL planks can be used in outdoor applications, but they should be protected from exposure to moisture and weathering.

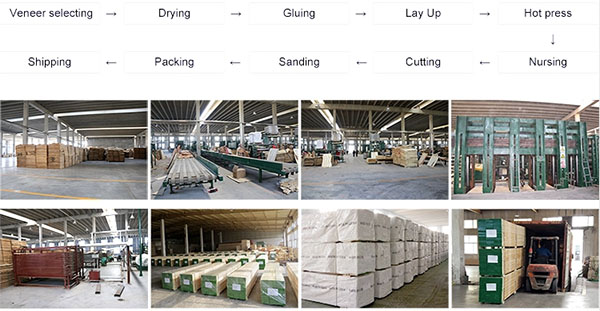

Q: How are HW Australia Pine LVL Scaffolding Planks manufactured?

A: LVL planks are made by layering thin wood veneers and bonding them together with an adhesive under heat and pressure. The resulting product is a strong and stable material that can be cut and shaped to suit a range of applications.

Q: How do I maintain and care for HW Australia Pine LVL Scaffolding Planks?

A: To maintain LVL planks, it is important to protect them from exposure to moisture and weathering and to inspect them regularly for signs of damage or wear. Any damaged or worn planks should be replaced promptly to ensure safety on construction sites.