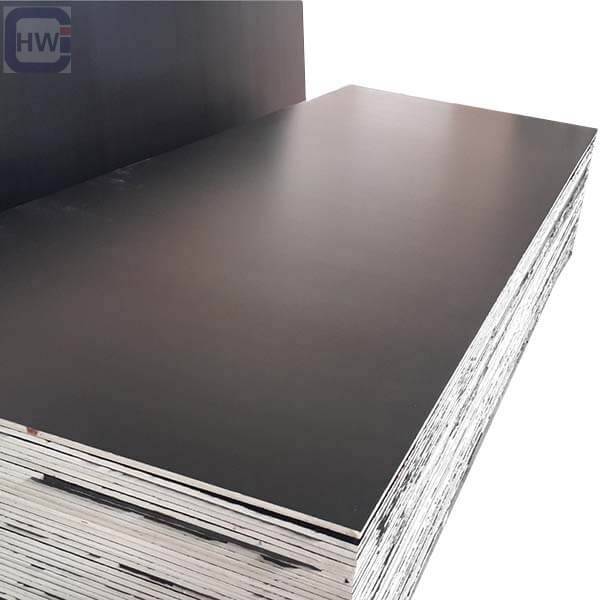

Finger Joint Strip Core Film Faced Plywood Board

Finger Joint Strip Core Film Faced Plywood Board is a type of engineered wood product used in construction and furniture making. It is made by gluing together thin layers of wood veneers, which are then pressed and bonded with an adhesive to create a strong and durable sheet of plywood.

The term “oversized finger joint” refers to the technique used to join together the shorter lengths of wood strips, which are then formed into a larger board. This jointing technique increases the strength and stability of the board.

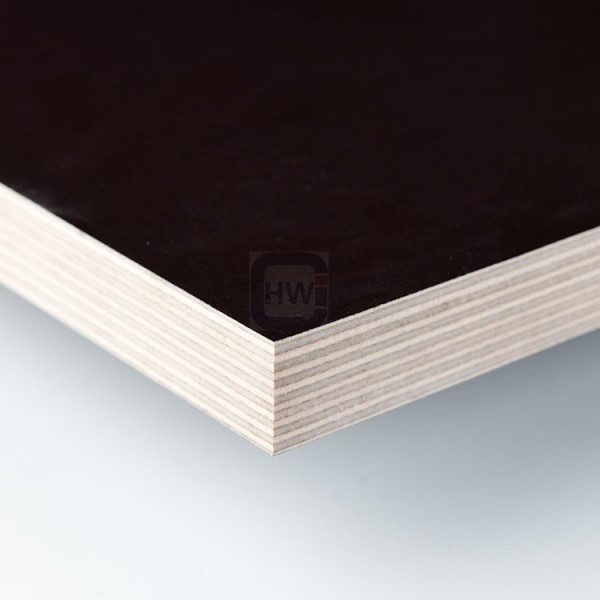

The core of the plywood board is made up of finger-jointed strips of wood, which are arranged in a cross-grain pattern to increase strength and stability. The face and back of the board are covered with a film or veneer, which provides a smooth and durable surface that can withstand heavy use and exposure to the elements.

Oversized finger joint strip core film-faced plywood board is commonly used in applications where strength, durability, and resistance to moisture are important. It is often used in concrete formwork, flooring, and exterior cladding, as well as in the manufacture of furniture and cabinetry.

Oversized Finger Joint Strip Core Film Faced Plywood Board Feature

1. Strength and durability: The finger-jointed core and cross-grain pattern of the board provides superior strength and durability compared to solid wood or other engineered wood products.

2. Moisture resistance: The film face and back veneers provide a waterproof surface that can withstand exposure to moisture, making it ideal for use in outdoor applications or in areas where moisture is present.

3. Easy to work with: Plywood boards are easy to cut, shape, and install, making them a popular choice for construction and furniture-making projects.

4. Versatility: The board can be used in a variety of applications, including concrete formwork, flooring, exterior cladding, and furniture and cabinetry making.

5. Sustainability: Plywood is an eco-friendly building material as it is made from renewable resources and is often manufactured using sustainable production methods.

6. Uniformity: The finger jointing technique used to join the wood strips creates a uniform appearance in the board, which can be desirable for certain applications.

7. Cost-effective: Plywood boards are generally less expensive than solid wood boards, making them a cost-effective option for many construction and furniture-making projects.

Plywood, film-faced plywood, Oversized Film Faced Plywood Board also known as clean water template, is produced according to GB 17656-2008. It is made of rotary cut veneers from Chinese poplars and high-quality waterproof glue and is processed by high temperature and high pressure. It can be used repeatedly for more than 10 times, without warping and deformation for its good water resistance character. It can be widely used in various concrete engineering such as high-speed railways, subways, and airport ports, as well as in infrastructure projects such as shear walls, vertical wall panels, bridges, dams and tunnel construction, civil construction, and commercial engineering. It could shorten the construction period: firstly, it is easy to de-mold, only one-seventh time of the steel mold de-molding; secondly, the surface is flat avoiding the secondary plastering process; thirdly, good insulation performance makes winter construction favorable.

Film-faced plywood, shuttering plywood, construction plywood, and concrete plywood, 18mm thickness is very popular, plywood can be made by full poplar core and finger joint core. We use good veneers, so their density is high with strong bearing capacity and long service life.

Parameters of Oversized Film-Faced Plywood Board

| Name | HW Oversize Film Faced Plywood | |

| Brand | HW | |

| Size | 2000x5400mm or upon request | |

| Thickness Tolerance | 18–30mm or upon request | ±0.5mm |

| Core | 100% Poplar or combi | |

| Film options: | Domestic Black or Brown film Dynea film | |

| Edge | Sealed with waterproof paint, paint color can be upon request | |

| Glue | Mr, Melamine, Phenolic WBP | |

| Hot press time | 2 times or 3 times for the whole panel | |

| Formaldehyde Emission level | Carb,E0,E1,E2 | |

| Moisture content | 6%-10% at the time of shipment | |

| Usage | Real estate construction /formwork panel | |

| Package | Outer packing: pallets are covered with plywood or carton boxes and strong steel belts | |

| Certification | CE, ISO, FSC Certified, CARB | |

| Delivery time | Within 2-3 weeks upon down payment or upon the opening of L/C | |

| Min Order | 1*20’ft | |

| PAYMENT TERM | TT or L/C | |

| Supply Ability | 5000 M3/per month | |

| MARK | HW is HW oversize/jumbo film-faced plywood for large sheet size demand. | |

Packaging and Containerization of Oversized Film Faced Plywood Board

Application:

Over-sized Film Faced Plywood used for RV/Truck Floor, Construction, Formwork system, etc.

FAQ

Q: What is the difference between oversized finger joint strip core plywood and regular plywood?

A: Oversized finger joint strip core plywood has a core made up of finger-jointed strips of wood, which are arranged in a cross-grain pattern to increase strength and stability. Regular plywood can have a core made up of either solid wood or other engineered wood products.

Q: What is the film face on the plywood board?

A: The film face is a waterproof veneer that covers the face and back of the board, providing a smooth and durable surface that can withstand exposure to moisture and heavy use.

Q: What are the applications of oversized finger joint strip core film-faced plywood board?

A: It is commonly used in concrete formwork, flooring, exterior cladding, and furniture and cabinetry making.

Q: Is oversized finger joint strip core film-faced plywood board environmentally friendly?

A: Yes, plywood is an eco-friendly building material as it is made from renewable resources and is often manufactured using sustainable production methods.

Q: Can oversized finger joint strip core film-faced plywood board be used for outdoor applications?

A: Yes, the waterproof film face and back veneers make it ideal for use in outdoor applications or in areas where moisture is present.