High Quality OSB for construction grade

Oriented Strand Board (OSB) is a type of engineered wood product that is commonly used in construction applications. It is made by compressing and bonding small strands of wood together with adhesive, which creates a strong and durable panel.

High-quality OSB for construction grade is specifically designed for use in structural applications that require a strong and stable panel. This type of OSB is manufactured using high-quality wood strands and advanced adhesive technology, which creates a panel that is resistant to warping, twisting, and delamination.

The panels are typically manufactured in large sizes, up to 8 feet wide and 24 feet long, which makes them ideal for use in applications such as roofing, flooring, and wall sheathing. The thickness of the panels can range from 7/16 inches to 1 1/8 inches, depending on the specific requirements of the application.

One of the main advantages of high-quality OSB for construction grade is its strength. The compressive strength of OSB is typically higher than that of plywood, which makes it an attractive option for use in applications that require a strong and stable panel. Additionally, OSB is more affordable than many other types of engineered wood products, which makes it a popular choice for use in cost-sensitive construction projects.

OSB Types

OSB/1 – General purpose boards and boards for interior fitments (including furniture) for use in dry conditions

OSB/2 – Load-bearing boards for use in dry conditions

OSB/3 – Load-bearing boards for use in humid conditions

OSB/4 – Heavy-duty load-bearing boards for use in humid conditions

High-Quality OSB for construction grade Advantages:

1. Strength and Durability: High-quality OSB is engineered to be strong and durable, with high compressive strength and resistance to warping, twisting, and delamination.

2. Versatility: OSB can be used for a wide range of construction applications, including roofing, flooring, and wall sheathing.

3. Large sizes: OSB panels can be manufactured in large sizes, up to 8 feet wide and 24 feet long, which makes them suitable for use in large-scale construction projects.

4. Affordability: OSB is typically more affordable than many other types of engineered wood products, which makes it a popular choice for use in cost-sensitive construction projects.

5. Sustainability: OSB is made from small wood strands that are typically sourced from sustainably managed forests, which makes it an environmentally friendly option.

6. Consistent quality: High-quality OSB is manufactured using advanced adhesive technology and rigorous quality control processes, which ensures that the panels have consistent strength and performance characteristics.

7. Easy to install: OSB is lightweight and easy to handle, which makes it easy to install in a variety of construction applications.

OSB technical data

|

Product Name

|

OSB

(Oriented Strand Board)

|

Glue

|

MDI glue, waterproof,

No formaldehyde

|

|

Factory

|

HW

|

Wood Material

|

Pine

|

|

Tolerance

|

±0.2mm in thickness,

|

Density

|

620kgs/CBM

|

|

Density tolerance |

±10% |

Moisture content |

≤10% |

|

elasticity modulus(parallel)

|

Average value (Mpa):≥3500

The minimum value (Mpa):≥2800

|

elasticity modulus (vertical)

|

Average value (Mpa):≥1400

The minimum value (Mpa):≥1120

|

|

Internal bond strength

|

Average value (Mpa):≥0.32

The minimum value (Mpa):≥0.256

|

Formaldehyde emission (mg/100g)

|

E0

|

Product Description

Product Advantages

1. High-quality raw material-Australian pine

(2) The pine wood structure is uniform, the density, thickness, and strength in the board are uniform, without voids, warpage, and deformation;

(3) Pine Wood has good nail-holding power and strong permeability.

(1) Adopting a new generation of technology materials without formaldehyde and adding MDI glue, the glue does not contain formaldehyde

(2) MDI glue is insoluble in water, and when it meets the moisture layer, it effectively prevents moisture from entering the core material;

(3) After reacting with wood molecules, new chemical bonds are formed to effectively bond the board body. The board produced has excellent nail-holding power and resistance to deformation.

stringent certifications such as CARB in the United States, F☆☆☆☆ in Japan, EPA, the U.S. Environmental Protection

Manufacturing Technique

Advanced OSB equipment

Packing&Shipping

|

Thickness

|

Pcs/Pallet

|

Pallets/40 HQ

|

Pcs/40HQ

|

Remarks

|

|

6mm

|

150

|

16

|

2400

|

For reference, the packing quantity can be changed according to the client’s requirement

|

|

8mm

|

100

|

18

|

1800

|

|

|

9mm

|

100

|

16

|

1600

|

|

|

11mm

|

82

|

16

|

1312

|

|

|

15mm

|

60

|

16

|

960

|

|

|

18mm

|

50

|

16

|

800

|

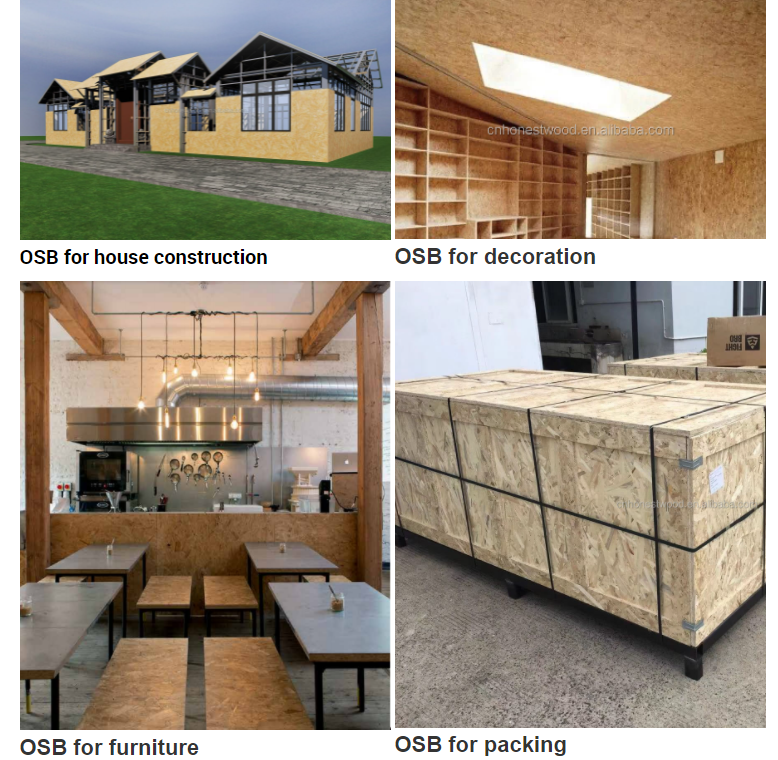

Product Application

* Roof/wall and floor sheathing for wooden frame houses

* Interior finishing, decoration

* Application in furniture and packaging industries

* Formwork, fences

FAQ

Q: What is high-quality OSB for construction grade?

A: High-quality OSB for construction grade is a type of engineered wood product that is specifically designed for use in structural applications that require a strong and stable panel.

Q: How is high-quality OSB made?

A: High-quality OSB is made by compressing and bonding small strands of wood together with adhesive. The panels are manufactured in large sizes and thicknesses, depending on the specific requirements of the application.

Q: What are the advantages of using high-quality OSB for construction grade?

A: The advantages of using high-quality OSB for construction grade include its strength, durability, affordability, versatility, and sustainability.

Q: What types of construction applications is high-quality OSB suitable for?

A: High-quality OSB is suitable for a wide range of construction applications, including roofing, flooring, and wall sheathing.

Q: How does high-quality OSB compare to other types of engineered wood products?

A: High-quality OSB is typically more affordable than many other types of engineered wood products, such as plywood. Additionally, OSB is more environmentally friendly than some other types of engineered wood products, such as particleboard.