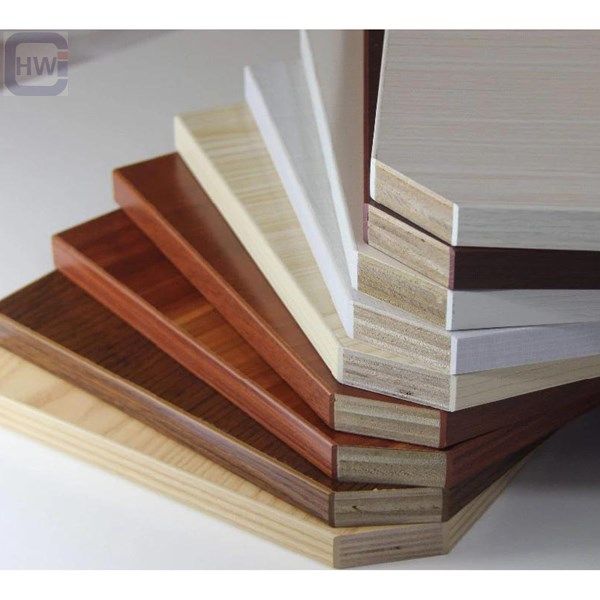

Melamine Faced Plywood

-

HW Furniture Grade Melamine Faced Plywood

· Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

· Face/Back: Melamine Paper/custom

· Core: Poplar/Eucalyptus/Combi

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–30mm/custom

· Glue:E0/E1/E2/Custom

-

HW High-Grade Melamine Faced Plywood

· Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

· Face/Back: Melamine Paper/custom

· Core: Poplar/Eucalyptus/Combi

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–30mm/custom

· Glue:E0/E1/E2/Custom

-

HW Melamine Paper Commercial Plywood

· Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

· Face/Back: Melamine Paper/custom

· Core: Poplar/Eucalyptus/Combi

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–30mm/custom

· Glue:E0/E1/E2/Custom

-

Melamine Paper Plywood

Melamine Paper Plywood

· Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

· Face/Back: Melamine Paper/custom

· Core: Poplar/Eucalyptus/Combi

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–30mm/custom

· Glue:E0/E1/E2/Custom

Melamine-Faced Plywood Introduction

Melamine-faced plywood (MFP) is a type of engineered wood panel that has a laminated surface made from melamine resin-impregnated decorative paper. It is commonly used in furniture, cabinetry, and interior wall paneling. And other decorative applications. MFP is made by bonding decorative paper with melamine resin to a plywood substrate under heat and pressure. The result is a durable, scratch-resistant surface that is easy to clean and maintain. The substrate can be made of different types of wood. Such as birch, poplar, or pine, depending on the desired properties and appearance of the final product. MFP is available in a wide range of colors, patterns, and textures. Which makes it a popular choice for designers and architects who want to achieve a specific look or style. It is also a cost-effective alternative to solid wood, veneer, or other decorative materials. Making it an attractive option for budget-conscious projects. Overall, MFP is a versatile and durable material that offers a practical and stylish solution for a variety of applications.Melamine Faced Plywood Feature

- Durable: Melamine-faced plywood has a strong and durable surface that is resistant to scratches, abrasions, and impacts. Making it ideal for high-traffic areas.

- Easy to clean: The surface of MFP is non-porous and easy to clean, which makes it a practical choice for applications where hygiene is a concern. Such as in kitchens or hospitals.

- Decorative: MFP is available in a wide range of colors, patterns, and textures. Which allows designers and architects to achieve a specific aesthetic or style.

- Cost-effective: Compared to solid wood or other decorative materials. MFP is a cost-effective alternative that can save money without sacrificing quality or appearance.

- Versatile: MFP can be used in a variety of applications. Including furniture, cabinetry, interior wall paneling, and more.

- Environmentally friendly: Many MFP manufacturers use sustainable wood sources and eco-friendly production methods. Making it a greener choice compared to other decorative materials.