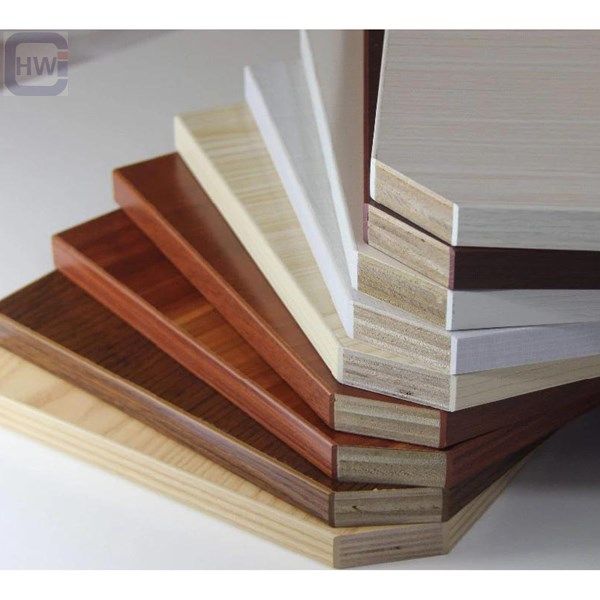

Melamine Board

-

HW Furniture Grade Melamine Faced Plywood

· Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

· Face/Back: Melamine Paper/custom

· Core: Poplar/Eucalyptus/Combi

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–30mm/custom

· Glue:E0/E1/E2/Custom

-

HW High-Grade Melamine Faced Plywood

· Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

· Face/Back: Melamine Paper/custom

· Core: Poplar/Eucalyptus/Combi

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–30mm/custom

· Glue:E0/E1/E2/Custom

-

HW Melamine Paper Commercial Plywood

· Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

· Face/Back: Melamine Paper/custom

· Core: Poplar/Eucalyptus/Combi

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–30mm/custom

· Glue:E0/E1/E2/Custom

-

Melamine Paper Plywood

Melamine Paper Plywood

· Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

· MOQ: 1X20’FCL

· Supply Ability: 5000CBM/Month

· Payment Terms: T/T or L/C

· Delivery Time: Within 20 days after deposit confirmation

· Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

· Face/Back: Melamine Paper/custom

· Core: Poplar/Eucalyptus/Combi

· Size: 1220x2440mm/1250x2500mm/custom

· Thickness:3–30mm/custom

· Glue:E0/E1/E2/Custom

Melamine Board Introduction

Melamine board is a type of engineered wood product that is made by compressing wood particles or fibers with a melamine resin. The resulting board is then covered with a decorative layer of paper or vinyl that has been impregnated with melamine resin, which provides a hard and durable surface. Melamine boards are widely used in the furniture industry for making cabinets, shelves, wardrobes, and other types of furniture. They are also used in the construction industry for interior wall cladding, ceiling tiles, and flooring. One of the main advantages of melamine boards is that they are highly resistant to scratches, stains, and moisture, making them a popular choice for areas that are prone to wear and tear. They are also available in a wide range of colors, patterns, and textures, making them suitable for a variety of decorative applications. Overall, melamine boards are a cost-effective and versatile option for a range of construction and furniture projects.Melamine Board Feature

- Durability: Melamine boards are highly resistant to scratches, stains, and moisture, making them ideal for areas that are prone to wear and tear.

- Versatility: They come in a wide range of colors, patterns, and textures, making them suitable for a variety of decorative applications.

- Affordability: Melamine boards are a cost-effective alternative to solid wood and other types of engineered wood products.

- Easy maintenance: They are easy to clean and maintain, requiring only a damp cloth or mild detergent to keep them looking new.

- Environmentally friendly: Many melamine boards are made from recycled wood fibers and use low-VOC adhesives, making them an eco-friendly option.

- Resistance to warping and shrinking: Melamine boards are less prone to warping and shrinking compared to solid wood, making them a reliable choice for furniture and construction projects.