Black Film Faced Plywood

-

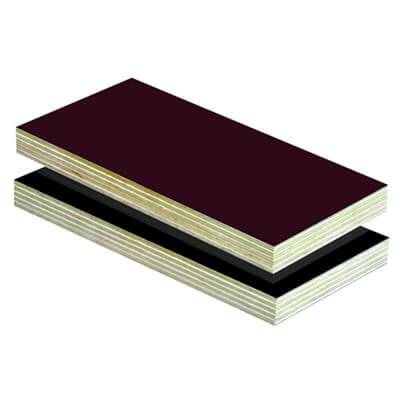

Black Film-Faced Plywood

Film Faced Plywood is also called Formwork Plywood, Shuttering Plywood, Concrete formwork. Film faced plywood is the special plywood with two sides coated with wearable and water proof film. The film is adhesive impregnated paper, which are different from melamine paper overlay, PVC, MDO and HDO. The function of the film is to protect the inside wood from moisture, water, weather and extend the plywood’s service life. Film Faced Plywood is an exterior plywood used in building and construction projects……

-

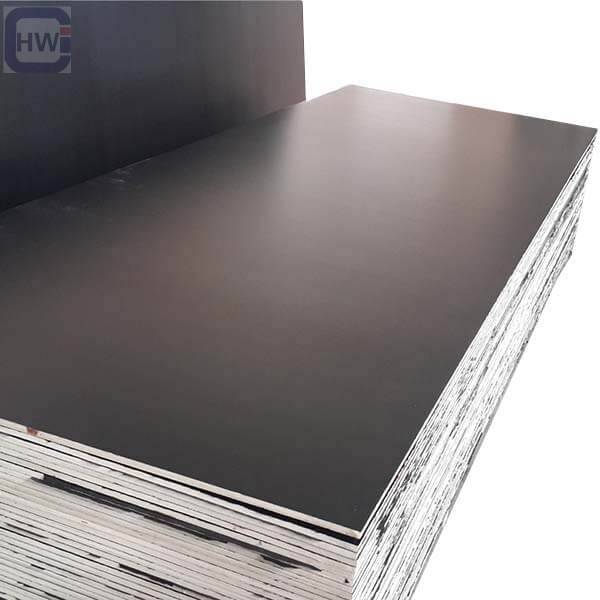

HW Black Oversize Film-Faced Plywood

Film Faced Plywood is also called Formwork Plywood, Shuttering Plywood, or Concrete formwork. Film-faced plywood is a special plywood with two sides coated with a wearable and waterproof film. The film is adhesive-impregnated paper, which is different from melamine paper overlay, PVC, MDO, and HDO. The function of the film is to protect the inside wood from moisture, water, and weather and extend the plywood’s service life. Film Faced Plywood is exterior plywood used in building and construction projects……

Black Film-Faced Plywood Introduction

Black Film Faced Plywood is a type of plywood that is commonly used in construction, particularly in concrete formwork. It is also known as phenolic film-faced plywood or simply film-faced plywood. The plywood is made by bonding layers of wood veneer together with a waterproof adhesive, and then coat both sides of the panel with a black phenolic resin film. The black film provides a smooth and durable surface that is resistant to moisture, abrasion, and chemicals. This kind of Plywood is designed to withstand the harsh conditions of concrete formwork and is commonly used in walls, columns, beams, and slabs. It can also be used in other applications where a durable and waterproof surface is required, such as truck and trailer flooring, scaffolding, and industrial shelving. The thickness of Black Film Faced Plywood ranges from 6mm to 25mm, and the standard size is 1220mm x 2440mm. It is also available in larger sizes, such as 1250mm x 2500mm and 1500mm x 3000mm. The plywood is typically graded based on the number of defects in the surface, with higher grades indicating fewer defects.Black Film-Faced Plywood Feature

- Durability: The phenolic film on both sides of the plywood makes it highly resistant to moisture, abrasion, and chemicals. This makes it ideal for use in harsh environments and conditions.

- Strength: The layers of wood veneer used to create the plywood provide high strength and stability, making it suitable for use in structural applications.

- Easy to use: The smooth and even surface of the plywood allows for easy and efficient application of formwork and other materials.

- Cost-effective: It is a cost-effective option for concrete formwork and other applications, providing high-quality performance at a reasonable price.

- Reusability: The plywood can be reused multiple times, reducing the need for frequent replacements and resulting in cost savings over time.

- Versatility: This Plywood can be used in a variety of applications beyond concrete formwork, including truck and trailer flooring, scaffolding, and industrial shelving.