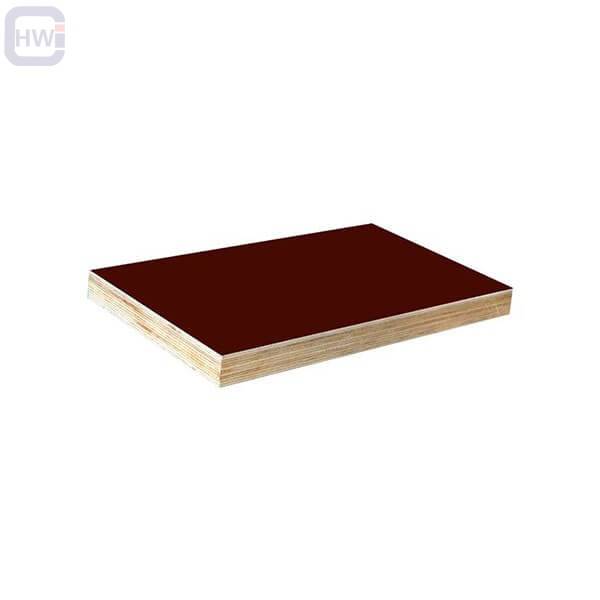

Brown Film Faced Plywood

-

Brown Film Faced Plywood

Film Faced Plywood is also called Formwork Plywood, Shuttering Plywood, or Concrete formwork. Film-faced plywood is a special plywood with two sides coated with a wearable and waterproof film. The film is adhesive-impregnated paper, which is different from melamine paper overlay, PVC, MDO, and HDO. The function of the film is to protect the inside wood from moisture, water, and weather and extend the plywood’s service life. Film Faced Plywood is exterior plywood used in building and construction projects……

Brown Film-Faced Plywood Introduction

Brown film-faced plywood, also known as black film-faced plywood or simply film-faced plywood, is a type of plywood that has a phenolic film layer on its surface. The film layer is usually made of paper impregnated with phenolic resin, which provides excellent water resistance and durability. The film layer can be either brown or black, and it is usually applied to both sides of the plywood. This gives the plywood a smooth and hard surface that can withstand wear and tear, as well as exposure to moisture, weather, and chemicals. This plywood is commonly used in construction and building applications, such as concrete formwork, scaffolding, and flooring. It is also used in the transportation industry for making truck and trailer floors. One of the main advantages of this plywood is its ability to resist water and moisture. This makes it an ideal material for use in damp and humid environments, as well as in areas with high exposure to water, such as swimming pools, docks, and bridges. Overall, brown film faced plywood is a versatile and durable building material that offers a range of benefits for a variety of applications.Brown Film Faced Plywood Feature

- Water Resistance: The phenolic film layer on the surface of the plywood provides excellent water resistance, making it suitable for use in damp and humid environments.

- Durability: The film layer also enhances the strength and durability of the plywood, making it resistant to wear and tear, as well as exposure to weather, chemicals, and abrasion.

- Smooth Surface: The film layer provides a smooth and hard surface, which makes it easier to clean and maintain.

- Versatility: The kind of plywood is suitable for a wide range of applications, such as concrete formwork, scaffolding, and flooring, among others.

- Easy to Work: The plywood can be easily cut, drilled, and shaped, making it easy to work with and customize for specific applications.

- Cost-Effective: It is generally more cost-effective than other types of building materials, making it an affordable option for construction and building projects.