HW Structural Plywood 4MM-30MM

Structural Plywood has been manufactured at our plant in China, for in excess of 15 years and has been used successfully in Asia, Australia, and New Zealand.

Structual plywood for strong, stable. Structural Plywood has been manufactured at our plant in China, for in excess of 15 years and has been used successfully in Asia, Australia, and New Zealand.

For domestic and light commercial structural and decorative applications manufactures structural plywood in a range of widths, lengths, thicknesses, and grades to AS/NZS2269 from Newzealand and Russia-sourced plantation Radiata Pine and Larch. Products are certified by Certmark.

Structural plywood is for use in all permanent structural and engineered applications.

A Bond is durable and permanent under conditions of full weather exposure and long-term stress.

Structural plywood should be preservative-treated to ensure it lasts its full-service life as it is manufactured from a range of hardwood and softwood timber species.

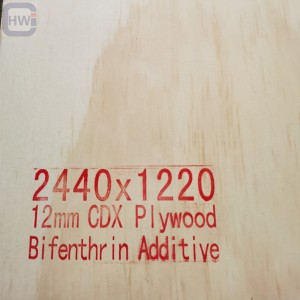

For termite and rot resistance, plywood can be treated to H2, H3, or H4 standards. Or for a lower-cost alternative can be manufactured with a bifenthrin glue line additive which provides termite resistance but is only suitable for use south of the tropic of Capricorn.

Testing and certification are carried out by Certemark International (CMI) and DNV.

Formply provides assurance of quality and consistency.

Introduction

HW Structural Plywood is a type of plywood that is designed and manufactured for use in load-bearing applications in the construction industry. It is made from high-quality hardwood species and is constructed with each layer’s grain running perpendicular to the previous layer, providing strength and stability.

HW Structural Plywood Feature

1. Strength: HW Structural Plywood is designed to be strong and durable, making it suitable for use in load-bearing applications in the construction industry. Its construction with each layer’s grain running perpendicular to the previous layer provides strength and stability.

2. Versatility: HW Structural Plywood is a versatile building material that can be used in a wide range of applications, including walls, floors, roofs, and structural framing. It is available in various thicknesses and sizes, making it suitable for both small and large construction projects.

3. Durability: HW Structural Plywood is manufactured to meet strict quality standards and is designed to withstand harsh weather conditions. It is resistant to moisture, rot, and pests, making it ideal for use in outdoor construction projects.

4. Compliance with standards: HW Structural Plywood is manufactured to meet strict quality standards, including the AS/NZS 2269 Plywood Structural standard. This means that builders and contractors can trust that the plywood will meet the necessary performance requirements for load-bearing applications in the construction industry.

| Normal Thickness | Sheet Size (mm) | Grade | Density (kg/cm) | Face and back | Core Materials | Moisture | Glue | Thickness Tolerance | Packing Unit ( sheets ) |

| 1/8inch (2.7-4.0mm) | 1200×2400 | A/B | 580 | Larch/ Pine | Larch/hardwood/ pine | 8-14 % | Waterproof Super E0 | +/-0.2mm | 150 / 400 |

| 1/2inch (12-12.7mm) | 1200×2400 | B/C | 550 | Larch/ Pine | Larch/hardwood/ pine | 8-14 % | +/-0.5mm | 70 / 90 | |

| 5/8inch (15-16mm) | 1200×2400 | C/C | 530 | Larch/ Pine | Larch/hardwood/ pine | 8-14 % | +/-0.5mm | 60 / 70 | |

| 3/4inch (18-19mm) | 1200×2400 | C/D | 520 | Larch/ Pine | Larch/hardwood/ pine | 8-14 % | +/-0.5mm | 50 / 60 |

Advantages of HW Structural Plywood

Manufactured from sustainably-grown plantation pine and Larch

Available in B, C, and D surface appearance grades

Sheet thicknesses: 3 to 40mm

Sheet dimensions: 2400/1800 × 1200mm

Supplied in F8/F27 stress grade

Uncoated high-appearance surface suitable for clear, stain, and paint finishes

Contains a second void-free layer under the surface veneer increasing protection

from moisture bubbles and high-point loads

Low formaldehyde emission (E0)

Application of HW Structural Plywood

Packaging and Containerization

FAQ

Q: What is HW Structural Plywood used for?

A: HW Structural Plywood is designed and manufactured for use in load-bearing applications in the construction industry. It can be used for walls, floors, roofs, and structural framing.

Q: What sizes are available for HW Structural Plywood?

A: HW Structural Plywood is available in various thicknesses, ranging from 4mm to 30mm. It is also available in standard sheet sizes of 2400mm x 1200mm or 2700mm x 1200mm. Other sizes may be available upon request.

Q: What is the difference between HW Structural Plywood and non-structural plywood?

A: HW Structural Plywood is designed and manufactured for use in load-bearing applications in the construction industry, while non-structural plywood is designed for use in non-load-bearing applications such as wall paneling, furniture, and decorative purposes.

Q: What are the benefits of HW Structural Plywood?

A: HW Structural Plywood is strong, durable, and versatile. Its construction with each layer’s grain running perpendicular to the previous layer provides strength and stability. It is also resistant to moisture, rot, and pests, making it suitable for outdoor construction projects.

Q: Is HW Structural Plywood environmentally friendly?

A: HW Structural Plywood is made from high-quality hardwood species that are a renewable resource. The plywood manufacturing process also uses advanced technologies and techniques to minimize waste and reduce environmental impact.