Pp Plastic Plywood Introduction

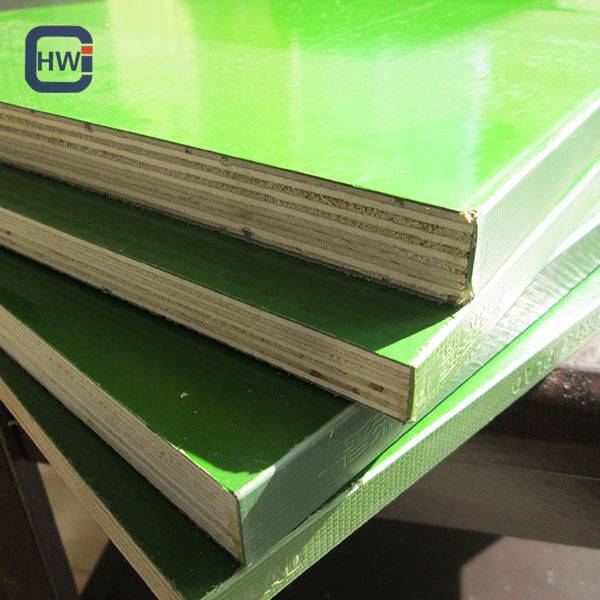

PP Plastic Plywood, also known as polypropylene plastic plywood, is a type of plywood that is made by combining a polypropylene plastic sheet with a wood-based core.

Plywood is made by sandwiching layers of wood veneer and gluing between two sheets of plastic.

Plywood is used in a variety of industries, including construction, transportation, and packaging. It is used in applications where moisture and chemical resistance are important factors. Such as in the construction of concrete formwork, truck bed liners, and shipping containers.

Plywood's ability to withstand exposure to water makes it popular in wet environments. Additionally, its resistance to many chemicals makes it ideal for use in industries where chemicals are present. It is also lightweight, making it easy to handle and transport.

Plywood, however, offers a wide range of benefits. It is strong, durable, and resistant to environmental factors such as moisture and heat/cold.

Feature

- Water resistance: This kind of plywood is resistant to water and moisture, making it ideal for use in wet environments. Such as bathrooms and kitchens, as well as outdoor applications.

- Chemical resistance: It is resistant to a wide range of chemicals, including those used in many industries.

- Lightweight: This Plywood is lightweight, making it easy to handle and transport.

- High strength: The PP Plastic Plywood has a wood core, which provides structural strength and stiffness. The plastic sheet provides additional durability.

- Weather resistance: This kind of Plywood can withstand exposure to various weather conditions, including extreme temperatures and sunlight.

- Easy to clean: It is easy to clean and maintain, making it a popular choice for applications where cleanliness is important.

FAQ

Q: What is PP Plastic Plywood?

A: Plywood is a type of plywood that is made by combining a polypropylene plastic sheet with a wood-based core. It offers strength, durability, and resistance to environmental factors that make it a versatile and reliable material for a wide range of applications.

Q: What are the advantages of PP Plastic Plywood?

A: Plywood has several advantages, including water resistance, chemical resistance, lightweight, high strength, weather resistance, and ease to clean. It is suitable for a variety of applications where moisture and chemical resistance are important factors, such as in the construction of concrete formwork, truck bed liners, and shipping containers.

Q: What are the common uses of PP Plastic Plywood?

A: Plywood is commonly used in building and construction, transportation, packaging, and furniture manufacturing. It is particularly popular in applications where moisture and chemical resistance are important factors, such as in the construction of concrete formwork, truck bed liners, and shipping containers.

Q: How is PP Plastic Plywood made?

A: Plywood is made by combining a polypropylene plastic sheet with a wood-based core using an adhesive. The wood core provides the structural strength and stiffness of the plywood, while the plastic sheet provides additional durability, water resistance, and chemical resistance.

Q: Is PP Plastic Plywood environmentally friendly?

A: PP Plastic Plywood is considered to be environmentally friendly because it is made from sustainable and renewable resources. Additionally, it can be recycled and reused, reducing waste and conserving resources.