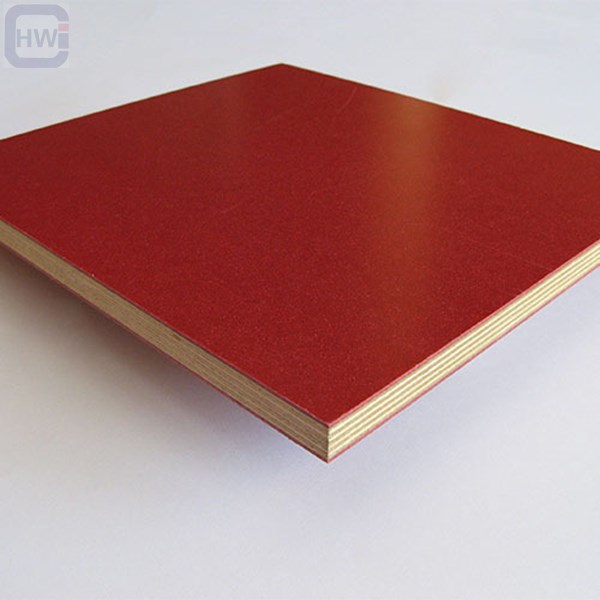

Red Film-Faced Plywood Introduction

Red Film Faced Plywood is a type of plywood that has a film coating on both sides of the panel, which gives it a red color. Plywood is a versatile building material used in construction and other outdoor applications. It's water-resistant, so it can be used in areas that are prone to flooding. It's also durable, so it will last for years in harsh environments.

The film on the surface of plywood is typically made from a synthetic polymer called phenolic resin. which is highly resistant to water, chemicals, and extreme temperatures. The film not only protects the surface of the plywood from damage but also provides a smooth surface that is easy to clean.

This Plywood is a popular choice for use in concrete formwork and scaffolding. It is also often used for making furniture, flooring, and decorative items due to its attractive appearance.

When purchasing this Plywood, be sure to check the quality of the wood. Look for the thickness, moisture content, and strength of the board. It is also important to store and handle the plywood properly to prevent damage and ensure its longevity.

Red Film-Faced Plywood Feature

- Water-resistant: The plywood has a film coating on both sides, which makes it resistant to water and moisture. This makes it suitable for outdoor applications.

- Durable: It is one of the strongest and most durable types of plywood. Making it ideal for use in construction and other heavy-duty applications.

- Smooth surface: The film coating provides a smooth surface that is easy to clean and maintain.

- Attractive appearance: The red color of the film coating on this plywood makes it attractive for decorative purposes.

- Versatile: This kind of Plywood is used for a wide range of applications. Including concrete formwork and decorative items.

- Resistant to chemicals and extreme temperatures: The film coating is made from phenolic resin. Which makes it resistant to chemicals, extreme temperatures, and scratches.

- Cost-effective: It is a cost-effective alternative to other building materials. Making it an ideal choice for large-scale construction projects.

FAQ

Q: What are the standard sizes of Red Film Faced Plywood?

A: Plywood typically comes in standard sizes of 1220mm x 2440mm, with thicknesses ranging from 9mm to 18mm.

Q: How is Red Film Faced Plywood made?

A: Plywood is made by bonding together thin layers of wood veneers with a waterproof adhesive, and then coat both sides of the panel with a film made from phenolic resin.

Q: What are the advantages of using Red Film-Faced Plywood?

A: Some of the advantages of using this Plywood include its water resistance, durability, smooth surface, attractive appearance, versatility, and cost-effectiveness.

Q: How should Red Film Faced Plywood be stored and handled?

A: Plywood should be stored in a dry, cool, and ventilated area to prevent moisture buildup, and should be handled carefully to avoid damaging the film coating.

Q: What is the difference between the Plywood and Black Film Faced Plywood?

A: The main difference between the Plywood and Black Film-Faced Plywood is the color of the film coating. Both types of plywood have similar features and properties, but some users may prefer one color over the other for aesthetic reasons.