F17 Formply

-

F17 Structural Formply

FORMPLY F17 1800 X 1200 X 17MM PLYWOOD

F17 Formply, 17mm Formply 1200*1800mm

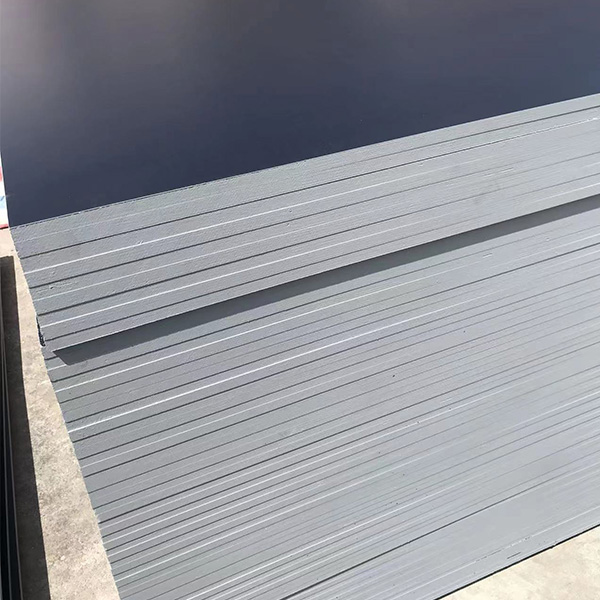

Size: 1220*1800mm, 1200*2400mm

Thickness: 17mm

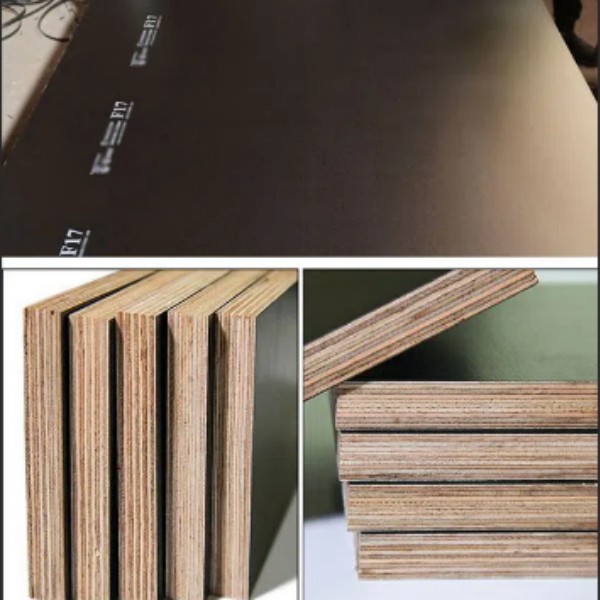

Core material: Hardwood, Birch, Pine, etc

Glue: Phenolic glue(72 hours in boiling water)

Face/Back: Dynea Film, Black/Brown Film, Class 2

Moisture Content: 6-10%

Application: Concrete Formwork, Construction, Wagon building, etc

-

F17 Structural Formply

FORMPLY F17 1800 X 1200 X 17MM PLYWOOD

F17 Formply, 17mm Formply 1200*1800mm

Size: 1220*1800mm, 1200*2400mm

Thickness: 17mm

Core material: Hardwood, Birch, Pine, etc

Glue: Phenolic glue(72 hours in boiling water)

Face/Back: Dynea Film, Black/Brown Film, Class 2

Moisture Content: 6-10%

Application: Concrete Formwork, Construction, Wagon building, etc

-

FORMPLY F17 1800 X 1200 X 17MM FORMWORK PLYWOOD

FORMPLY F17 1800 X 1200 X 17MM PLYWOOD

F17 Formply, 17mm Formply 1200*1800mm

Size: 1220*1800mm, 1200*2400mm

Thickness: 17mm

Core material: Hardwood, Birch, Pine, etc

Glue: Phenolic glue(72 hours in boiling water)

Face/Back: Dynea Film, Black/Brown Film, Class 2

Moisture Content: 6-10%

Application: Concrete Formwork, Construction, Wagon building, etc

F17 Formply Introduction

F17 Formply is a type of high-quality plywood that is commonly used in construction and building projects. It is specifically designed for concrete formwork applications, where a smooth, flat surface is required to create a high-quality finish on concrete surfaces. The "F17" designation refers to the plywood's strength and durability rating. The F17 family is made from high-grade, plantation-grown hardwood veneers that are glued together using a waterproof resin adhesive. The plywood is then pressed and sanded to create a smooth, flat surface that is ideal for use in concrete formwork. Family is often used in high-stress applications, such as in the construction of bridges, tunnels, and high-rise buildings. It is also commonly used in residential construction projects for forming walls, columns, and slabs. The F17 family is known for its strength, durability, and resistance to moisture and weathering. It is able to withstand heavy loads and extreme weather conditions without warping or cracking, making it an ideal choice for construction projects in a variety of environments.F17 Formply Feature

- High strength: F17 family has a strength rating of F17, which means it can withstand high levels of stress and load without breaking or warping.

- Durability: The hardwood veneers used in the F17 family are selected for their strength and durability. This makes the plywood resistant to impact, wear and tear, and weathering.

- Moisture resistance: F17 formerly is manufactured with a waterproof adhesive and is designed to resist moisture, making it suitable for use in wet and humid environments.

- Smooth surface: F17 family has a smooth, flat surface that provides a high-quality finish to concrete surfaces. This makes it ideal for applications where a smooth, even finish is required.

- Easy to work with: F17 family can be easily cut and shaped to fit any formwork design. It is also easy to handle and transport, which makes it a popular choice for construction projects.

- Sustainability: F17 family is made from sustainably sourced, plantation-grown hardwood, which makes it an eco-friendly choice for construction projects.