HW Red EV Plywood

Product Details of HW Red EV Plywood

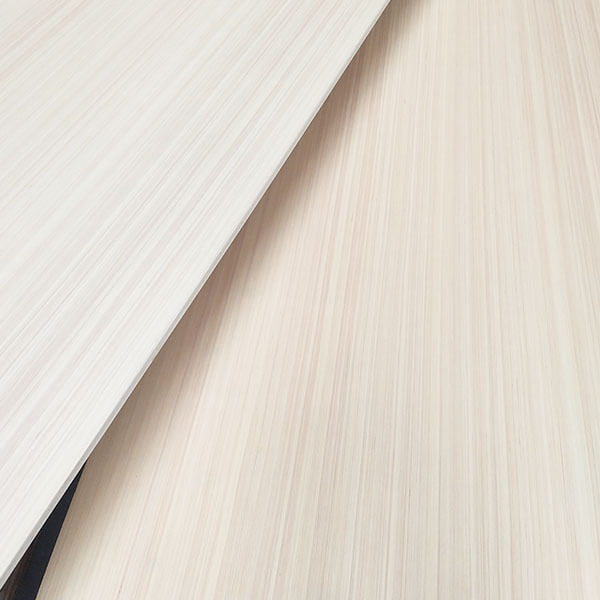

EV veneers also named reconstituted veneers laminated plywood is one of our best-selling furniture grade boards. We usually recommend customers for the Poplar core, combi core, and eucalyptus core strive for high-end quality products. surface species can be a lot of different series, like oak, teak, poplar, cherry, and so on and we are working with several big mills of recon veneers producer for multichoice. and this product is ideal for the furniture grade and counter top material first choice.

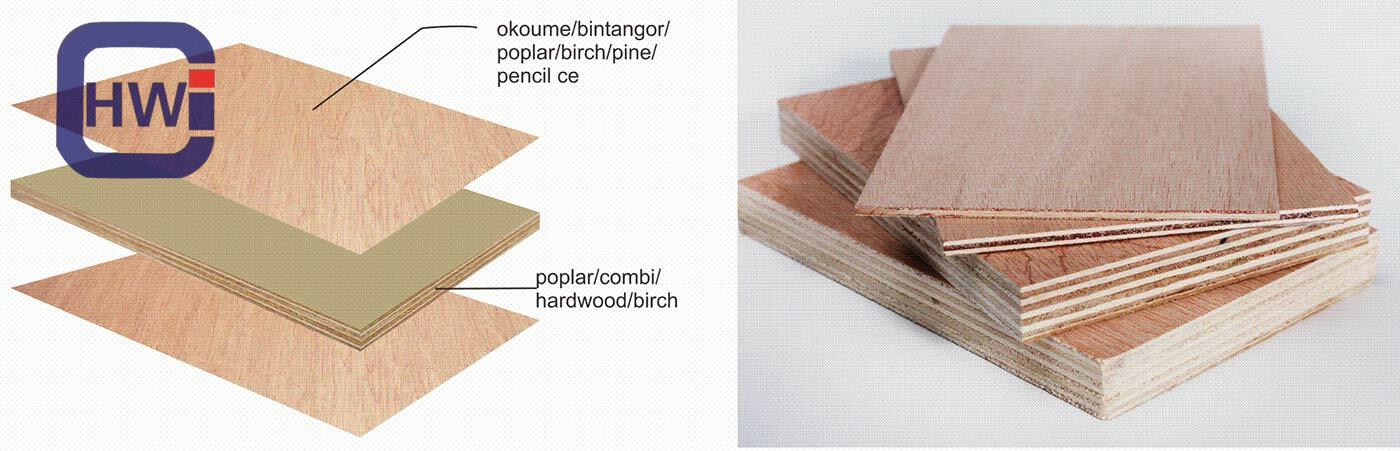

Plywood is comprised of multiple plies of wood veneer giving it high stability, suitable for both indoor and outdoor use. It is usually used for Automotive Interiors, Furniture, Room Decoration, Construction, and Packing.

Below are the advantages, of why customers choose our plywood:

Good veneer price and the poplar core quality is great. could be used for the inner part.

Hard and durable quality, make them long usage life.

Factory quality guarantee, quality problems? contact us.

Well packed, and has good protection while shipping.

HW Red Plywood Feature

1. Strength and durability: HW Red Plywood is made from dense and durable hardwood species, which gives it excellent strength and resistance to wear and tear. It can withstand heavy loads and impact, making it a good choice for flooring, walls, and structural applications.

2. Moisture resistance: HW Red Plywood has good moisture resistance, thanks to the high-quality adhesive used to bond the hardwood veneers. This makes it suitable for use in areas with high humidity, such as bathrooms, kitchens, and outdoor spaces.

3. Stability: The cross-grain construction of HW Red Plywood gives it excellent stability and resistance to warping, twisting, and cracking. This makes it a reliable choice for long-term applications, such as flooring and furniture.

4. Aesthetic appeal: The natural reddish-brown color of the hardwood veneer gives HW Red Plywood a warm and rich appearance that is well-suited for decorative and aesthetic purposes. It can be stained, painted, or finished to achieve a variety of looks.

5. Versatility: HW Red Plywood is a versatile building material that can be used in a wide range of applications, including flooring, cabinetry, furniture, and wall paneling. It is also available in different thicknesses and grades to meet specific project requirements.

Face Veneers

Bintangor

natural-birch-plywood

poplar-plywood-china-supplier

Product Parameters of HW Red EV Plywood

| Product Name | HW 5-30MM Commercial Plywood for Furniture | ||

| Size | 1220x2440mm/1250x2500mm/ or as client’s requirement | ||

| Thickness | 5-30mm | ||

| Thickness Tolerance | +/-0.2mm (thickness<6mm), +/-0.3~0.5mm (thickness≥6mm) | ||

| Face/Back | E-Wood, Okoume, Ilomba, Poplar, Birch, Bintangor, Hardwood, Pine, Pencil Cedar, Keruing, Agathis, Meranti, ect. | ||

| Core | Poplar, hardwood, eucalyptus, Okoume, birch, pine, combi, etc. | ||

| Joint Way of The Core | Overlap joint, end joint, scarf joint, or finger joint | ||

| Glue | E0, E1, E2, MR, Melamine or WBP | ||

| Grade | B/BB,BB/BB,BB/CC,DBB/CC; ect | ||

| Density | 520~700kg/m3 | ||

| Technical Parameters | Moisture Content | <12% | |

| Water Absorption | ≤10% | ||

| Modulus of Elasticity | ≥5000Mpa | ||

| Static Bending Strength | ≥30Mpa | ||

| Surface Bonding Strength | ≥1.60Mpa | ||

| Internal Bonding Strength | ≥0.90Mpa | ||

| Screw Holding Ability | Face | ≥1900N | |

| Edge | ≥1200N | ||

| Usage & Performance | Plywood is widely used for Automotive Interior ,furniture, decoration, construction and packing. With good properties, such as, easy fabricability, high bending strength, strong screw holding ability, heat resistance, anti-static, long-lasting, and no seasonal effect. | ||

| MOQ | 1×20’FCL | ||

| Supply Ability | 5000cbm/month | ||

| Payment Terms | T/T or L/C at sight | ||

| Delivery Time | Within 20 days after receiving the deposit or original L/C at sight | ||

| Certification | CE, FSC, EUTR, CARB,EPA, JAS, ISO | ||

| Mark | EV veneers also named reconstituted veneers laminated plywood is one of our best-selling furniture grade of boards. We usually recommend customers for the Poplar core, combi core, and eucalyptus core strive for high-end quality products. surface species can be a lot of different series, like oak, teak, poplar, cherry, and so on and we are working with several big mills of recon veneers producer for multichoice. and this product is ideal for the furniture grade and countertop material first choice. | ||

Delivery Instructions of HW Red EV Plywood

| Packing | Standard Export Pallet Packing | Inner Packing | The pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | The pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/50cbm | |||

Packaging and Containerization

Application of HW Red EV Plywood

1. Construction: HW Red EV plywood is commonly used in construction for its strength and durability. It can be used for walls, floors, roofs, and other structural elements.

2. Furniture: HW Red EV plywood is a popular choice for furniture makers due to its strength and resistance to moisture. It is commonly used for cabinets, tables, chairs, and other furniture pieces.

3. Packaging: HW Red EV plywood is commonly used in the packaging industry for shipping containers, pallets, and crates. It is known for its strength and durability, which helps to protect the contents during transport.

4. Marine applications: HW Red EV plywood is commonly used in the marine industry for boat building, dock construction, and other applications where moisture resistance is essential.

5. Decorative applications: HW Red EV plywood can be used for decorative applications such as wall paneling, ceilings, and decorative accents. It is available in a variety of finishes and can be painted or stained to match any decor.

HW Red EV Plywood FAQ

Q: What is HW Red Plywood used for?

A: HW Red Plywood is a versatile building material that can be used in a variety of applications, including flooring, cabinetry, furniture, and wall paneling. Its strength, durability, moisture resistance, stability, and natural beauty make it a popular choice among builders, carpenters, and DIY enthusiasts.

Q: What types of hardwood species are used to make HW Red Plywood?

A: HW Red Plywood is typically made from dense and durable hardwood species such as birch, oak, or maple. These woods are selected for their strength, durability, and aesthetic appeal.

Q: Is HW Red Plywood suitable for outdoor use?

A: HW Red Plywood has good moisture resistance and can withstand exposure to the elements, but it is not recommended for extended outdoor use without proper finishing or sealing. It is also important to note that HW Red Plywood is not rated for structural use and should not be used in load-bearing applications without proper reinforcement.

Q: What sizes and thicknesses is HW Red Plywood available in?

A: HW Red Plywood is available in a variety of sizes and thicknesses to suit different project requirements. Standard sheet sizes include 4′ x 8′, 4′ x 10′, and 5′ x 10′, while thicknesses range from 1/4″ to 3/4″. Custom sizes and thicknesses may also be available upon request.

Q: How do I care for and maintain HW Red Plywood?

A: To maintain the natural beauty and durability of HW Red Plywood, it is recommended to keep it clean and dry and to avoid exposing it to excessive moisture or direct sunlight. Regular dusting and occasional cleaning with a mild soap and water solution are usually sufficient. It is also important to avoid using harsh chemicals or abrasive cleaners, as they can damage the surface of the plywood.