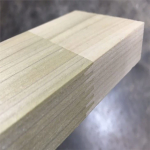

AA Grade Paulownia Finger Joint Boards

AA Grade Paulownia Finger Joint Boards are a type of engineered wood product made from finger-jointed paulownia wood. Finger-jointing is a process where short pieces of wood are joined together to create longer, straighter boards. The resulting AA Grade Paulownia Finger Joint Boards have a uniform appearance and are highly stable, making them ideal for use in furniture, cabinetry, and decorative items.

The AA grade designation indicates that the boards have been carefully selected for their high quality and uniform appearance. The paulownia wood used in these boards is known for its strength, lightweight, and resistance to rot and pests. Additionally, AA Grade Paulownia Finger Joint Boards have a natural resistance to moisture and can be used in damp or humid environments.

These boards are available in various thicknesses and dimensions, making it easy to find the right size for any woodworking project. They are also lightweight, which makes them easy to handle and install. The smooth surface of the boards makes them ideal for painting or staining to achieve the desired finish.

Parameter

- Item Name: Without Knots Paulownia Finger Joint Boards

- Size: 1220*2440mm or 1200*2400mm or as customized

- Thickness: 3mm-45mm or as customized

- Color: Natural wood color

- Moisture content: 8%-10%

AA Grade Paulownia Finger Joint Boards Feature

1. High-quality material: AA Grade Paulownia Finger Joint Boards are made from carefully selected paulownia wood pieces that have been finger-jointed together to create a high-quality and uniform product.

2. Stability: The finger-jointing process creates boards that are highly stable and less likely to warp or twist over time.

Lightweight: Paulownia wood is a lightweight material, making the resulting finger-jointed boards easy to handle and install.

3. Moisture resistance: Paulownia wood is naturally resistant to moisture, making AA Grade Paulownia Finger Joint Boards ideal for use in humid or damp environments.

4. Attractive appearance: AA Grade Paulownia Finger Joint Boards have a uniform appearance and a smooth surface, making them an attractive choice for a variety of woodworking applications.

5. Versatility: AA Grade Paulownia Finger Joint Boards are available in various thicknesses and dimensions, making them suitable for a wide range of applications, including furniture, cabinetry, wall paneling, and decorative items.

6. Sustainability: Paulownia trees grow quickly and can be harvested within 7-10 years, making them a highly sustainable and renewable resource.

Without Knots Paulownia Finger Joint Boards Characteristics:

- Wear Resistance

Tung wood has the unique characteristics of resistance to decay and acid and alkali, not easy to wear, so the wardrobe is very durable.

- Beautiful Texture And Bright Color

Tung material has a beautiful, delicate texture, the natural design is particularly good, do the wardrobe show a good-looking appearance.

- Easy To Carve And Dye

Tung wood is not easy to split, but the wood is soft, easy to work, easy to carve, and easy to dye. Chest words can carve on its door plank with various decorative patterns, increasing its adornment sex.

In addition, it also has the advantages of not being permeable to smoke, or dampness and not easy to be eaten by insects.

Product Picture

Processing-paulownia wood timber

Quality-Control Paulownia Timber

Packing & Delivery

Careful Packaging

1. Specialized Sealing Films are sealed on the six surfaces of the board’s package.

2. Thicker Corrugated Papers are packaged Six-Sides for protecting all of the faces and angles.

3. Three/Five-Lays Plywood Boards are packed Six-Sides for resistance from outside.

4. Toughness Packing Belts are strapped strongly on the outside of the Package.

5. Stronger Wood Pallets at the bottom for making the Unloading easier for shipment receiving.

Fast Delivery

1. 3 km distance of the national road from our Factory to the High-Way Entry.

2. 30 container trailers or more we can arrange for the delivery.

3. 500 km distance of the national high-way road from our factory to the Qingdao Port.

4. 5 hours or less of transport time, the cargo can be delivered to the Port for shipment.

FAQ

Q: What is the difference between AA Grade and other grades of paulownia finger joint boards?

A: AA Grade Paulownia Finger Joint Boards are made from carefully selected, high-quality pieces of paulownia wood that have been finger-jointed together to create a uniform product. Lower grades of finger-jointed boards may contain knots, irregularities, or other imperfections.

Q: What are some common applications for AA Grade Paulownia Finger Joint Boards?

A: AA Grade Paulownia Finger Joint Boards are versatile and can be used for a variety of applications, including furniture, cabinetry, wall paneling, and decorative items.

Q: How do I care for AA Grade Paulownia Finger Joint Boards?

A: AA Grade Paulownia Finger Joint Boards require minimal maintenance. You can clean them with a damp cloth and mild soap, and avoid exposing them to extreme temperatures or prolonged exposure to direct sunlight.

Q: Can AA Grade Paulownia Finger Joint Boards be stained or painted?

A: Yes, AA Grade Paulownia Finger Joint Boards can be stained or painted to achieve the desired look for your woodworking project. The smooth surface of the boards provides a good base for finishes.

Q: Are AA Grade Paulownia Finger Joint Boards strong enough for structural applications?

A: AA Grade Paulownia Finger Joint Boards are strong enough for many structural applications. However, it is important to consult with an engineer or other qualified professional to ensure that the boards are suitable for your specific project.