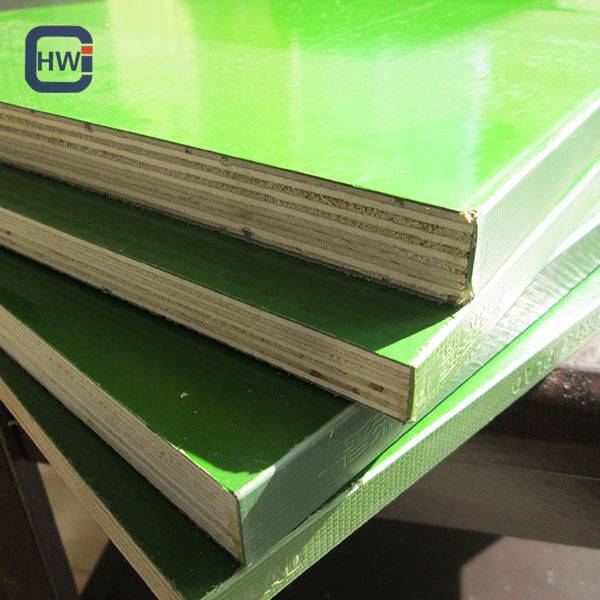

Green PP Plastic Faced Plywood

Description of Green PP Plastic Faced Plywood

Green PP Plastic Faced Plywood is a type of plywood that is coated with a layer of polypropylene plastic on one or both sides. This plastic layer provides extra protection to the plywood, making it more resistant to water, moisture, and wear and tear.

Green PP Plastic Faced Plywood is commonly used in construction projects where the plywood will be exposed to the elements or where durability is important. It is also popular in the transportation industry for applications such as truck bed linings and trailer flooring.

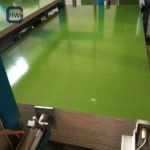

One advantage of Green PP Plastic Faced Plywood is that it is lightweight and easy to handle, while still providing strength and durability. It also has a smooth surface, which makes it easy to clean and maintain.

However, it is important to note that Green PP Plastic Faced Plywood can be more expensive than traditional plywood. Additionally, some types of plastic coatings may not be biodegradable, which could be a concern for those looking for eco-friendly materials.

| Length | 2440-2500mm |

| Wide | 1220-1250mm |

| Thickness | 12-15-18-21mm |

- Easy to dismount, release agent-free, nonstick cement, smooth finishing.

- Light in weight, easy to use, and can be cut to various sizes.

- More reuse times than normal film-faced plywood.

- Waterproof performance and wear & tear resistant.

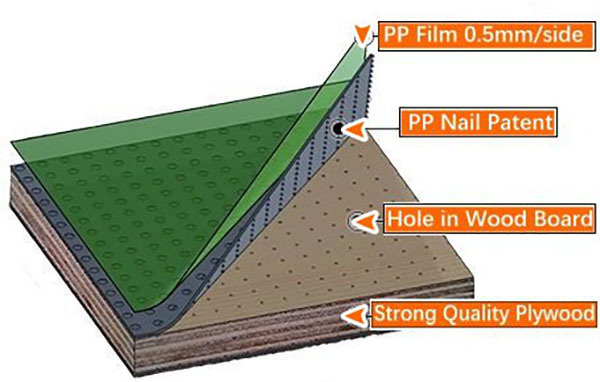

Product Details of Green PP Plastic-Faced Plywood:

PP plastic-coated plywood panels are made of wear-resisting and corrosion-resisting 0.5mm thickness PP Plastic on both sides coating and connecting to the inner plywood core.

Here the physical and mechanical properties are much higher than traditional film-faced plywood. This results in excellent properties:

- high mechanical cohesiveness

- high abrasion resistance

- water and weatherproof

- reusability(more than 30 times)

- excellent chemical resistance

- recyclable

Now, our PP Plastic Coated Plywood has been used widely in the construction field around the world, such as in Southeast Asia, the Middle East, and Europe markets.

Delivery Instructions of Green PP Plastic-Faced Plywood:

| Packing | Standard Export Pallet Packing | Inner Packing | The pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | The pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/50cbm | |||

Packaging and Containerization of Green PP Plastic-Faced Plywood:

Application of Green PP Plastic-Faced Plywood:

Green PP Plastic Faced Plywood is used for Construction, Formwork Systems, etc.

FAQ

Q; What is Green PP Plastic-Faced Plywood?

A: Green PP Plastic Faced Plywood is a type of plywood that is coated with a layer of polypropylene plastic on one or both sides. This plastic layer provides extra protection to the plywood, making it more resistant to water, moisture, and wear and tear.

Q: What are the advantages of Green PP Plastic-Faced Plywood?

A: The key advantages of Green PP Plastic Faced Plywood are its durability, lightweight nature, smooth surface, resistance to chemicals and weather, and versatility. It is also an eco-friendly option if made using recycled plastic.

Q: What are the applications of Green PP Plastic-Faced Plywood?

A: Green PP Plastic Faced Plywood is commonly used in construction projects where the plywood will be exposed to the elements or where durability is important. It is also popular in the transportation industry for applications such as truck bed linings and trailer flooring. It can be used in a wide range of applications, including furniture making.

Q: Is Green PP Plastic-Faced Plywood more expensive than traditional plywood?

A: Green PP Plastic Faced Plywood can be more expensive than traditional plywood, but it offers additional benefits such as increased durability and weather resistance.

Q: Is Green PP Plastic-Faced Plywood eco-friendly?

A: Green PP Plastic Faced Plywood can be an eco-friendly option if made using recycled plastic. However, it is important to note that not all types of plastic coatings are biodegradable, so it’s important to choose a product that meets your eco-friendly needs.