What exactly does truck deck plywood mean?

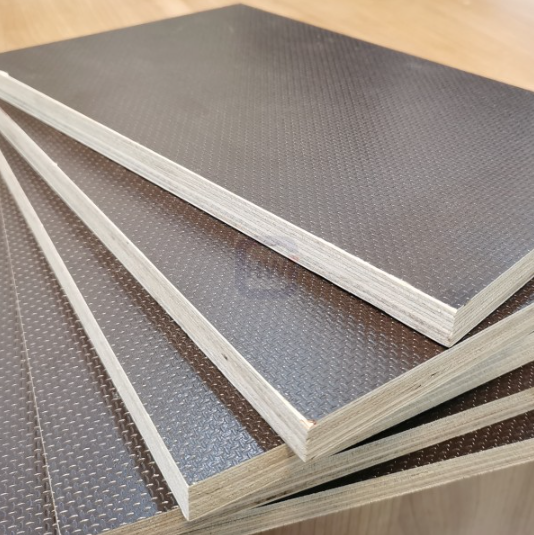

- Truck deck plywood is a specific kind that acts as the main flooring material in these heavy-duty vehicles. It is frequently referred to simply as “deck plywood” in the context of trucks and trailers. Plywood used for truck decks is designed to endure the strains of frequent loading and unloading, large loads, and the wear and tear involved with long-distance transportation. It is made to be incredibly strong and tough to withstand the rigours of the road.

- Safety is of the utmost importance in the transportation sector. To avoid accidents, truck plywood is made with anti-slip features. This feature lowers the possibility of accidents and property damage by keeping cargo and crew secure during travel. Plywood is frequently coated or treated to fend off moisture intrusion. This is necessary to safeguard the wood’s integrity and avoid problems like decay, which might jeopardize the truck’s floor’s structural integrity. Although plywood for truck decks must be anti-slip, it also provides a smooth surface that simplifies loading and unloading cargo. Its design finds a mix of comfort and grip. Plywood for truck decks is sometimes cut to meet the precise measurements of the truck or trailer. This guarantees a tight, seamless fit necessary for the best performance and security.

What is the purpose of truck deck plywood?

Truck deck plywood, sometimes called anti-slip or non-slip plywood, is a unique variety of plywood created to improve traction and safety in various applications. The flooring of trucks, trailers, and other heavy-duty vehicles is where it is most frequently used. Let’s study the many uses of truck plywood as we go deeper into the industry.

Flooring for trucks and trailers: One of the most popular applications for anti-slip plywood is flooring for trucks and trailers. This plywood has been designed to prevent people and cargo from sliding or slipping during transit. It assists in preserving stability and lowers the chance of accidents, particularly when loading and unloading cargo.

- Industrial Settings:

Anti-slip plywood has applications outside of the transportation industry. Its non-slip surface is advantageous for loading docks, manufacturing floors, and walkways in factories and warehouses. It guarantees employees can walk about securely, even in greasy or damp environments.

- Construction sector:

Scaffolding platforms and walkways in the construction sector employ anti-slip plywood. As a result, the probability of accidents on building sites, which are frequently full of dangers, is reduced.

- Marine Applications:

This plywood is also utilized in marine applications because of its resistance to moisture and slip-resistant qualities. It may be found on docks and boat decks, providing stability in sometimes slick and damp environments.

- Do-it-yourself projects:

Some use anti-slip plywood to build ramps, steps, or flooring in wet environments like basements or outdoor decks.

The installation process for truck plywood:

Truck anti-slip plywood can be attached using screws or other fasteners depending on the particular use and needs. To guarantee appropriate performance and safety, it’s crucial to adhere to the installation instructions provided by the manufacturer.

What are the benefits of using XUZHOU CHANGYU WOOD truck deck plywood?

With its distinctive qualities and design, truck deck plywood offers a variety of advantages that make it a vital option for the flooring of trucks, trailers, and other heavy-duty vehicles. Let’s explore these benefits in further detail:

- Increased Safety:

In the transportation sector, safety comes first. Truck anti-slip plywood is made to lower the possibility of accidents by offering a superb grip surface. This is particularly important during loading and unloading procedures since there is a considerable chance of slipping and falling. This plywood’s anti-slip qualities prevent such accidents and ensure the safety of both employees and cargo.

Enhanced Durability:

During their operating lifetime, heavy-duty trucks are subjected to tremendous stress, such as the weight of their load, continuous vibrations, and exposure to various weather conditions. These difficulties may be overcome thanks to the extraordinary durability of anti-slip plywood. Its sturdy design guarantees that it can withstand the rigours of regular use, extending the flooring of the truck’s lifespan.

- Water Resistance:

Truck anti-slip plywood is frequently coated or treated to withstand water. This is crucial because moisture may cause problems like rot and decay that compromise the flooring’s structural integrity. This plywood’s ability to withstand moisture enables it to operate well over time, especially in damp or humid environments.

- Simple Maintenance:

A truck’s flooring must be spotless and in good condition for safety and appearance. The smooth surface of anti-slip plywood makes cleaning and maintaining it simpler. Regular maintenance and cleaning are simpler, saving truck drivers time and effort.

- Goods Protection:

Truck anti-slip plywood also helps to safeguard the goods being transported and ensure the crew’s safety. Because of its non-slip surface, objects are less likely to move or slide during transit, lowering the possibility of breakage or damage.

- Custom meet:

To ensure a snug and seamless installation, anti-slip plywood may be cut specifically to meet the truck or trailer floor measurements. This specific strategy maximizes the effectiveness and safety of the flooring.

Conclusion:

The transportation sector should invest in the usage of truck deck plywood. Our numerous advantages are provided, including increased safety, durability, dampness resistance, simple maintenance, and cargo protection. Operators may improve their trucks’ overall performance and safety, lowering the chance of accidents and ensuring that commodities are delivered securely. 2014, we significantly improved our production technology, equipment, and workforce following our new plan. XUZHOU CHANGYU WOOD boosted the automatic machines, improved employee training, and then identified new manufacturing technology to fulfil client orders. To satisfy the demands of high-end consumers, we update and do away with the original low-standard goods while concentrating on creating furniture boards for environmental protection, RV plywood, and high-grade HPL plywood for environmental protection with a higher technological content.

Post time: 26 9 月, 2023