When it comes to construction or woodworking projects, one of the critical factors to consider is the cost of materials. Among these materials, structural plywood price is a versatile and commonly used option. In this guide, I’ll provide an in-depth look at structural plywood prices. I’ll cover what structural plywood is, factors that influence its cost, tips for finding the best prices, and answer some common questions about this essential building material.

Understanding Structural Plywood

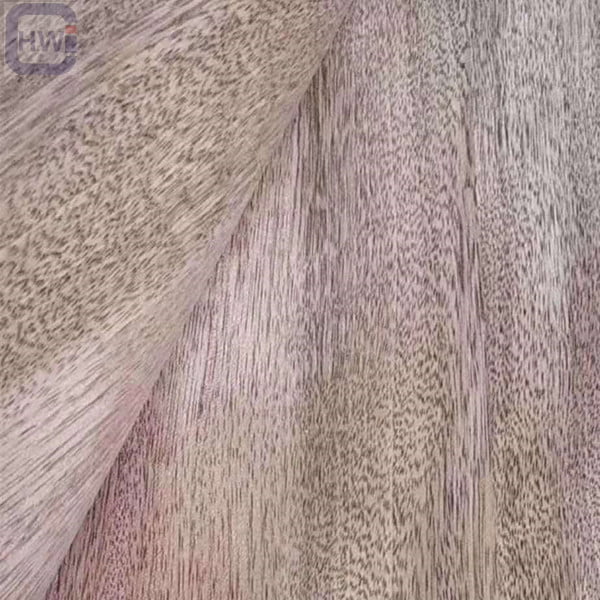

Before diving into the cost of structural plywood price, let’s clarify what it is. Structural plywood is a type of plywood that’s specifically engineered for structural applications. It’s constructed by bonding layers of wood veneers with adhesive to create a sturdy and stable panel. The quality and characteristics of structural plywood can vary, but it’s generally known for its strength and versatility.

Types of Structural Plywood

There are various types of structural plywood, each designed for specific purposes. Some common types include:

- CDX Plywood: CDX plywood is an economical option often used in construction. It’s known for its durability and is suitable for sheathing, roofing, and subflooring.

- OSB (Oriented Strand Board): While not technically plywood, OSB is often used as a more affordable alternative. It’s made from compressed wood strands and offers good structural integrity.

- Marine Plywood: As the name suggests, marine plywood is designed for water-related applications. It’s highly water-resistant and used in boat construction and dock building.

- Treated Plywood: Treated plywood is impregnated with preservatives to resist rot and decay. It’s commonly used in outdoor projects.

- Structural Plywood for Flooring: This type is engineered to handle the demands of flooring applications, providing a stable and durable surface.

Factors Affecting Structural Plywood Prices

The cost of structural plywood can vary widely due to several factors. Understanding these factors will help you make informed decisions when purchasing plywood for your project.

1. Plywood Grade

Plywood comes in different grades, with A being the highest quality and D being the lowest. The grade affects both the appearance and performance of the plywood. A higher grade typically means a higher price.

2. Plywood Thickness

The thickness of the plywood is a significant price determinant. Thicker plywood is more expensive, but it also offers greater structural integrity and is suitable for heavier loads.

3. Type of Wood

The type of wood used in the plywood affects its price. Plywood made from hardwoods like oak tends to be more expensive than softwood options like pine. The choice of wood can also impact the plywood’s durability and appearance.

4. Specialty Features

Some structural plywood comes with specialty features, such as fire resistance, pressure treatment, or moisture resistance. These features can add to the cost but may be necessary depending on the project’s requirements.

5. Market Demand

Like any other commodity, structural plywood prices can fluctuate with market demand. Economic conditions, seasonal factors, and global supply can all influence the cost of plywood.

6. Brand and Supplier

Different brands and suppliers may offer plywood at varying price points. It’s essential to research and compare prices to find the most cost-effective option without compromising on quality.

How to Find the Best Structural Plywood Prices

Now that we’ve covered what impacts structural plywood prices, let’s explore some tips for finding the best deals.

1. Do Your Research

Before making a purchase, research the specific type of structural plywood you need. Understand the grade, thickness, and features required for your project. Having a clear understanding of your needs will help you avoid overpaying for unnecessary features.

2. Compare Prices

Don’t settle for the first quote you receive. Reach out to multiple suppliers and compare their prices. You can do this by visiting local stores, contacting online retailers, or even using price comparison websites.

3. Consider Bulk Purchases

If your project requires a significant amount of plywood, consider buying in bulk. Many suppliers offer discounts for larger quantities, which can result in significant cost savings.

4. Explore Online Marketplaces

Online marketplaces and auction websites can be excellent sources for finding discounted plywood. Just be sure to verify the quality and reputation of the seller before making a purchase.

5. Buy Off-Season

Plywood prices can vary seasonally. If your project allows for flexibility in timing, consider purchasing plywood during the off-season when prices may be lower.

6. Check for Sales and Promotions

Keep an eye out for sales, promotions, and special offers from suppliers. These events can provide an excellent opportunity to buy high-quality plywood at reduced prices.

7. Negotiate

Don’t be afraid to negotiate with suppliers. Many are willing to work with you on pricing, especially if you’re buying in larger quantities.

Frequently Asked Questions

Q1: What is the cost difference between structural plywood and regular plywood?

A1: Structural plywood tends to be more expensive than regular plywood due to its specialized construction and higher quality. The exact price difference depends on factors such as grade, thickness, and type of wood.

Q2: Can I use structural plywood for non-structural applications to save on costs?

A2: It’s possible to use structural plywood for non-structural purposes, but it might be cost-prohibitive. For non-structural projects, you can consider alternatives like sheathing or regular plywood to reduce costs.

Q3: Are there any ways to reduce the cost of structural plywood without sacrificing quality?

A3: To lower costs, consider factors like the type of wood, grade, and thickness. Choosing a more cost-effective combination while maintaining the required specifications for your project can help reduce expenses.

Q4: Can I haggle on plywood prices at a lumberyard or home improvement store?

A4: Yes, you can often negotiate prices at lumberyards or home improvement stores, especially if you’re buying in larger quantities. Polite and respectful negotiation can lead to cost savings.

Q5: What are the most cost-effective types of structural plywood for general construction projects?

A5: CDX plywood and OSB are cost-effective options for general construction projects. They offer a good balance of price and performance for non-specialized applications.

Conclusion

Navigating the world of structural plywood price doesn’t have to be a daunting task. By understanding the factors that influence costs and following the tips for finding the best prices, you can confidently select the right plywood for your project without breaking the bank. Whether you’re building a new deck, constructing a shed, or working on a larger construction endeavor, knowing how to find affordable yet high-quality structural plywood is a valuable skill. So, embrace the possibilities and make informed choices when it comes to the price of structural plywood price for your next project.

Post time: 14 10 月, 2023