Architects, engineers, and construction professionals are continually looking for cutting-edge solutions which will benefit the environment while creating new buildings. A notable such material is a polypropylene (PP) plastic plywood, made by XUZHOU CHANGYU WOOD. This amazing product has innumerable advantages for sustainability, and this article will outline how this material can shape the future of the building industry.

I. Understanding PP Plastic Plywood

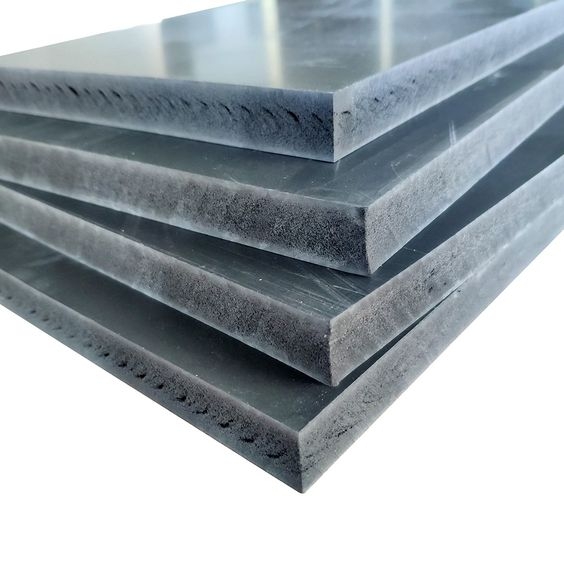

PP plastic plywood is a composite material made from layers of polypropylene plastic and other reinforcing fibers. Unlike traditional plywood made from wood veneers, PP plastic plywood is entirely synthetic, making it an ideal alternative for those seeking sustainable construction options. XUZHOU CHANGYU WOOD, a renowned manufacturer in the industry, produces high-quality PP plastic plywood that meets rigorous standards for strength, durability, and environmental performance.

II. Environmental Benefits of PP Plastic Plywood

Reduced Deforestation

By utilizing PP plastic plywood, construction professionals can significantly reduce the demand for traditional timber, thus combating deforestation. Traditional plywood production relies on logging trees, which contributes to the loss of valuable forest ecosystems. PP plastic plywood, being entirely synthetic, eliminates the need for logging and helps preserve our precious forests.

Recyclability and Reusability

One of the standout features of PP plastic plywood is its recyclability and reusability. Unlike many conventional building materials that end up in landfills at the end of their lifecycle, PP plastic plywood can be easily recycled and transformed into new products. This closed-loop recycling system reduces waste and conserves resources, making it a truly sustainable choice for the construction industry.

III. Performance Advantages

Durability and Water Resistance

PP plastic plywood offers exceptional durability and water resistance, making it suitable for various construction applications. Unlike traditional plywood, which can degrade when exposed to moisture, PP plastic plywood remains structurally intact and unaffected by water. This property makes it an excellent choice for building applications where moisture is a concern, such as exterior cladding, roofing, and bathroom installations.

Lightweight and Versatile

In addition to its durability, it is lightweight, making it easier to transport and handle during construction. Its versatility allows it to be used in a wide range of applications, including formwork, flooring, furniture, and interior partitions. Its lightweight nature also reduces the overall weight of the structure, potentially leading to energy savings during transportation and installation.

IV. Energy Efficiency and Insulation

PP plastic plywood demonstrates excellent insulation properties, contributing to energy-efficient building designs. By incorporating this material into walls, floors, and roofs, construction projects can reduce heat transfer, resulting in improved thermal comfort and lower energy consumption. The insulation provided by PP plastic plywood also helps regulate interior temperatures, reducing the need for excessive heating or cooling.

Ⅴ. XUZHOU CHANGYU WOOD: Leading the Charge in Sustainable Building

XUZHOU CHANGYU WOOD stands at the forefront of eco-friendly building solutions, with its commitment to producing high-quality PP plastic plywood. As a leading manufacturer, they have invested heavily in research and development to refine their production processes, ensuring that their products meet rigorous sustainability standards.

Innovation and Technology

The success of XUZHOU CHANGYU WOOD can be attributed to their innovative approach to manufacturing PP plastic plywood. By integrating cutting-edge technology and sustainable practices, the company has achieved a balance between cost-effectiveness and environmental responsibility.

Collaborating for a Greener Future

XUZHOU CHANGYU WOOD actively collaborates with architects, builders, and construction companies to promote the adoption of PP plastic plywood. By raising awareness about the benefits of this eco-friendly material and providing reliable supply chains, they encourage the industry to embrace sustainable building practices.

Durability Meets Sustainability: PP Plastic Plywood in Structural Applications

It is a cutting-edge building material derived from a blend of high-quality polypropylene and traditional wood fibers. The result is a composite material that inherits the best properties of both components. On one hand, the polypropylene imparts exceptional durability, water resistance, and weatherproofing capabilities to the plywood, making it ideal for outdoor applications. On the other hand, the integration of wood fibers ensures a natural aesthetic appeal, structural stability, and reduced carbon footprint compared to traditional all-plastic alternatives.

1. Durability Redefined

One of the primary reasons it has garnered significant attention in the construction world is its unparalleled durability. Unlike conventional plywood, which is susceptible to rotting, warping, and pest infestations, PP plastic plywood remains virtually impervious to these threats. Its water-resistant properties make it ideal for coastal structures or projects in humid climates. Furthermore, the material’s resistance to UV radiation ensures that it maintains its structural integrity and appearance over extended periods of exposure to sunlight.

2. Sustainability at Its Core

PP plastic plywood stands as a beacon of sustainability in the construction industry. By combining wood fibers with polypropylene, the material drastically reduces the demand for virgin plastics. This reduction directly translates to a decreased carbon footprint and less dependence on fossil fuels. Additionally, the sourcing of wood fibers from sustainably managed forests ensures the material’s renewable nature. As a result, PP plastic plywood provides builders and engineers with an eco-friendly alternative that helps protect natural resources and contributes to a circular economy.

3. Applications of PP Plastic Plywood

The versatility of it enables its application in a wide range of structural projects. From exterior cladding and roofing to formwork and interior partitions, the material has proven its worth across various construction scenarios. Its weather-resistant properties make it particularly suitable for outdoor decking, pergolas, and garden furniture. Moreover, the material’s ability to withstand heavy loads and extreme weather conditions makes it a reliable choice for temporary structures and emergency shelters.

Conclusion

Sustainability in the building industry is of utmost importance, and XUZHOU CHANGYU WOOD’s PP plastic plywood is the perfect material for architects, engineers, and construction workers looking to meet this challenge. Utilizing this material comes with a number of added benefits, such as durability, recyclability, and exceptional performance while allowing us to reduce our environmental impact. By taking advantage of PP plastic plywood’s innovation-fueled potential, we can revolutionize the way we build and create resilient, resource-based structures for a greener tomorrow.

Post time: 7 7 月, 2023