Brief Introduction of Film Faced Plywood:

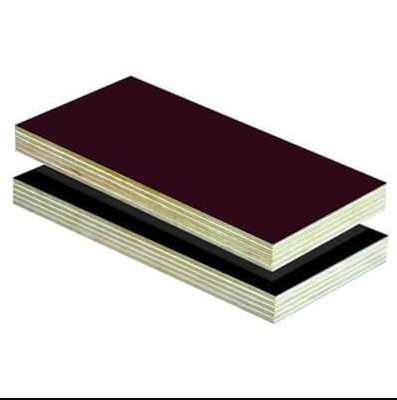

Film faced plywood is a form of plywood specially made for use in buildings and other outside applications where the wood would be exposed to moisture, weather, and severe weights. It is sometimes referred to as shuttering plywood or marine plywood. Concrete formwork, the temporary structure used to hold and shape concrete until it sets, is frequently made using it in the construction industry. For your particular project, selecting the correct grade and thickness of film-faced plywood is crucial because the specifications may change based on the weight, amount of exposure to the weather, and how frequently you intend to reuse the formwork. Its longevity and utility may be increased with appropriate storage and upkeep, such as keeping it dry and clean.

What is the function of film faced plywood?

Film faced plywood is a unique type of plywood with wearable and water-resistant film covering both sides. The film is made of paper impregnated with adhesive, as opposed to melamine paper overlay, PVC, MDO, and HDO.

The film’s purpose is to prolong the useful life of the plywood by protecting the inside wood from moisture, water, and the elements. Movie Faced Exterior plywood is known as plywood and is utilized in building and construction operations.

- The primary use of this plywood in the construction sector is as a dependable material for making concrete formwork. Its main function is to give temporary pouring and shaping platforms for concrete until it settles and reaches the necessary strength. Here is a more thorough description of how it works:

- This plywood serves as a stable and flat platform for casting concrete, first and foremost. Its homogeneous and visually attractive appearance results from the concrete adhering well to the surface thanks to the smooth and waterproof film overlay. For the construction of buildings and ornamental concrete, this is especially crucial.

- This plywood is highly valued for its resilience to dampness and bad weather. It protects the plywood layers underneath from water penetration, avoiding warping, delamination, and deterioration from moisture exposure. Due to its toughness, the formwork keeps its structural integrity during the curing of the concrete. It is a cost-effective option for building projects because it is also reusable. Its durability prevents material waste and prices from rising, promoting economic and environmental sustainability.

What are the reasons behind the increasing popularity of Black Film-Faced Plywood?

The demand for black film faced plywood in the building sector has significantly increased in recent years. Numerous compelling factors, from aesthetic appeal to useful benefits, have drawn attention to this trend. This blog article will examine the main causes of the rising use of black film-faced plywood in construction projects.

Modern aesthetics and aesthetic appeal

The distinctive and modern appearance of black film-faced plywood is one of the most obvious factors contributing to its rising popularity. Black has always been connected to refinement and elegance in design. It may provide architectural and construction projects with a clean and sophisticated appearance when utilized as the surface for concrete formwork. Architects and builders like the finish because of the aesthetic contrast created by the black surface and the natural colour of the concrete. Aesthetics are prioritized heavily in modern architecture and design. Black film-faced plywood fits this trend perfectly, making it the material of choice for applications where aesthetics is important. The black surface adds a distinctive and striking accent to high-end residential complexes, commercial structures, or contemporary urban infrastructure.

Enhanced Performance and Durability

The fundamental qualities of conventional equivalents, such as structural strength and water resistance, are also shared by black film-faced plywood. However, it frequently has a thicker, stronger film covering, which increases its durability. It is appropriate for difficult building conditions and projects because of its increased endurance. The black film-faced plywood’s overlay is thicker and strengthened with superior phenolic resin. This resin offers excellent resistance to moisture, chemicals, and abrasion. As a result, black film-faced plywood can withstand exposure to adverse weather, water, and even chemical spills without degrading or warping. Because of its improved resilience will last longer, necessitating fewer replacements overall and resulting in construction cost savings.

Excellent Concrete Finish

Making a homogeneous and smooth surface for concrete casting is one of the main uses of film faced plywood. Black film-faced plywood is the best option in this case. When the concrete is set and demolded, the smooth surface guarantees correct concrete adhesion and provides an outstanding finish. This characteristic is especially useful in applications involving architectural and ornamental concrete, where the final look of the concrete surface is crucial. The texture and colour of the concrete are highlighted by the black film-faced plywood’s dark background, producing a striking contrast that enhances the final structure’s overall aesthetic appeal. It makes sense that designers and builders working on projects with complicated or exposed concrete surfaces prefer black film-faced plywood.

Modularity in Design

Beyond its visual appeal, this plywood provides adaptability in design. Creative uses for its dark surface are possible in building and architectural ideas. When the formwork is in use, it may be used as a blank canvas for creative designs, images, or stencils. Additionally, it may be used with other materials to give concrete distinctive textures and patterns. This adaptability offers a world of creative possibilities for architects and designers looking to push the boundaries of conventional construction aesthetics.

Which benefits does Faced Plywood offer?

Enhanced Resistance to UV

The increased UV protection of black film-faced plywood is another useful benefit. This resistance is essential in outdoor building projects where formwork may be exposed to direct sunlight for lengthy periods. Conventional film-faced plywood may deteriorate or become discolored when exposed to UV radiation over time. With enhanced UV protection, black film-faced plywood keeps its stability and visual appeal even after extended exposure to the sun.

- Simpler to Clean and Maintain

Plywood with a black film face is simple to keep up and clean. Its slick, non-porous surface makes removing stains and concrete residues simple. Regular upkeep guarantees that the plywood keeps its beauty and functionality for an extended period, increasing its cost-effectiveness.

- Ecological Points to Think About

The building sector is increasingly concerned with sustainability. Environmentally friendly adhesives and sustainable wood sources frequently produce black film-faced plywood. This aligns with the industry’s growing emphasis on minimizing its environmental impact. Sustainable building materials are ethical and a selling advantage for clients and investors who value eco-friendly business practices.

- High-Level Quality Control

We frequently follow stringent quality control guidelines to ensure high-end goods. This implies that contractors and builders can rely on the consistency and dependability of black film-faced plywood for their projects. Consistent quality reduces the possibility of flaws or performance problems, giving people who use it for building purposes peace of mind.

Conclusion:

Established in 2002, XUZHOU CHANGYU WOOD has a wealth of skilled labour and wood material resources. It is situated in the heart of the Huai Hai economic zone. We always concentrate on wood material solutions in building, furniture manufacturing, and automotive interior panels. We always construct a lovely and clean name, CHANGYU WOOD, which promises honest and high business standards with our valued clients. We are seeking sustainable use of wood resources via quality first.

Post time: 7 9 月, 2023