Australia LVL Scaffold Plank

Laminated Veneer Lumber (LVL) scaffold planks are a popular choice for scaffolding in Australia. LVL is an engineered wood product that is made by layering thin sheets of wood veneer together with adhesive, which creates a strong and durable panel.

Here’s some more information about LVL scaffold planks in Australia:

1. Size: LVL scaffold planks are typically manufactured in sizes ranging from 225mm to 75mm wide, and up to 6 meters long.

2. Strength: LVL scaffold planks are strong and durable, with high load-bearing capacity, which makes them ideal for use in scaffolding applications.

3. Safety: LVL scaffold planks are designed to be slip-resistant and have a textured surface that helps to prevent slips and falls.

4. Compliance: In Australia, LVL scaffold planks must comply with the requirements of the Australian Standards for Scaffolding, which sets out the minimum standards for scaffold planks used in construction.

5. Environmental sustainability: LVL scaffold planks are made from sustainably managed forests, and the manufacturing process uses low levels of formaldehyde emissions, making them an environmentally friendly choice for construction projects.

6. Cost-effective: LVL scaffold planks are generally more affordable than other types of engineered wood products, such as glulam beams or plywood, which makes them a popular choice for construction projects in Australia.

Australia LVL Scaffold Plank

LVL-engineered wood planks

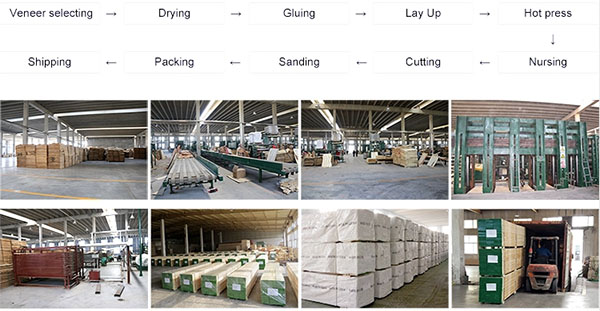

LVL (Laminated Veneer Lumber) is a new construction material. It can be customized to create high-value products for residential, commercial, formwork, and scaffolding applications.

Construction Grade LVL (laminated veneer lumber)

Parameters of Australia LVL Scaffold Plank:

| Raw material | New Zealand radiate pine and Russia Larch |

| Size | T( 38/42) * W( 225/230) *L( 1000/1500/2500/3000/3900/6000-12000)mm |

| Glue | WBP glue with 72 hours of hot water boiling, Melamine glue with 8 hours of hot water boiling |

| Density | 560-660kgs/cbm |

| MC | 8-12% |

| Certificate | CE/ SGS/AS4357/FSC/ISO |

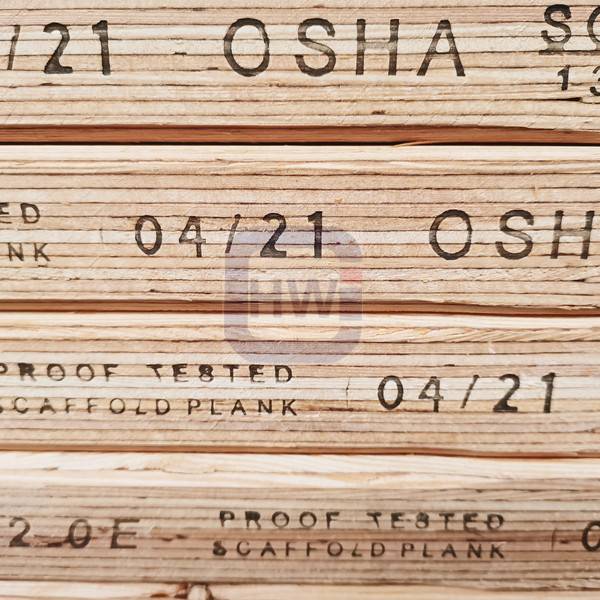

| Standard | OSHA middle duty, AS1577 heavy duty |

| End | Painting, or with metal cab |

Features & Advantages of Australia LVL Scaffold Plank:

1. High Strength: LVL scaffold planks are engineered to be strong and durable, with high load-bearing capacity, which makes them suitable for use in scaffolding applications.

2. Slip-resistant Surface: LVL scaffold planks have a textured surface that helps to prevent slips and falls, which makes them a safe option for use in construction projects.

3. Compliance with Standards: LVL scaffold planks must comply with the Australian Standards for Scaffolding, which sets out the minimum standards for scaffold planks used in construction, ensuring that they meet the required safety and performance standards.

4. Environmentally Friendly: LVL scaffold planks are made from sustainably managed forests, and the manufacturing process uses low levels of formaldehyde emissions, making them an environmentally friendly choice for construction projects.

5. Versatility: LVL scaffold planks are available in a range of sizes and lengths, which makes them suitable for use in a wide range of scaffolding applications.

6. Cost-effective: LVL scaffold planks are generally more affordable than other types of engineered wood products, such as glulam beams or plywood, which makes them a popular choice for construction projects in Australia.

Trade Terms of Australia LVL Scaffold Plank:

1. FOB (Free on Board): This term is used when the buyer is responsible for arranging and paying for the shipment of the LVL scaffold planks from the manufacturer’s warehouse to the port of departure in Australia. Once the LVL scaffold planks are loaded onto the shipping vessel, the responsibility transfers to the buyer.

2. CIF (Cost, Insurance, and Freight): This term is used when the seller is responsible for arranging and paying for the shipment of the LVL scaffold planks to the port of destination in Australia, including insurance coverage. The cost of the LVL scaffold planks and the shipping charges are included in the total price paid by the buyer.

3. EXW (Ex Works): This term is used when the buyer is responsible for arranging and paying for the shipment of the LVL scaffold planks from the manufacturer’s warehouse in Australia to their final destination. The seller is only responsible for making the LVL scaffold planks available for pickup at their warehouse.

4. CFR (Cost and Freight): This term is used when the seller is responsible for arranging and paying for the shipment of the LVL scaffold planks to the port of destination in Australia, but the buyer is responsible for arranging and paying for the customs clearance and delivery to their final destination.

5. Payment Terms: The payment terms for LVL scaffold planks vary depending on the supplier and the buyer’s creditworthiness. Common payment terms include 30 days net, where the buyer pays within 30 days of receiving the LVL scaffold planks, or a letter of credit, where the buyer’s bank guarantees payment to the seller upon receipt of the LVL scaffold planks.

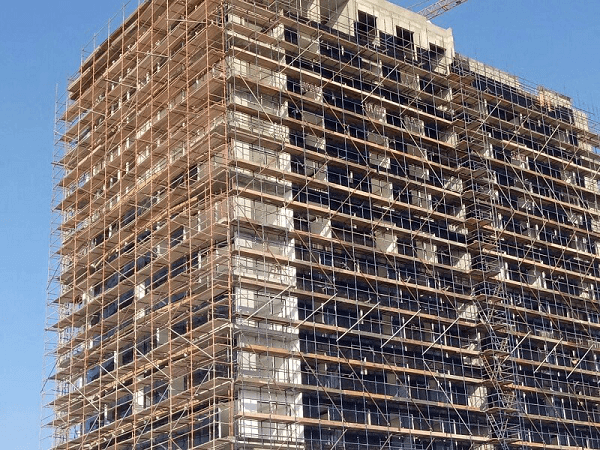

Pine LVL Scaffolding Plank is used for Construction, Formwork Systems, Bridge engineering, oil field engineering, etc.

Properties of LVL Scaffolding plank

1. Enhanced durability and safety (OSHA)

2. Unrivalled structural rigidity, stability, and strength

3. Proven to at least twice as long as solid wood equivalents

4.10% lighter than solid wood equivalents

5.No metal end band required

6.No ongoing maintenance or remedial repairs required

7. Excellent electrical insulation properties

8. Excellent anti-corrosive and chemical properties

Applications & comments of Australia LVL Scaffold Plank:

Used in place of metal scaffold boards or conventional timber. LVL Scaffold planks are affordable, tough, and long-lasting, especially in corrosive environments. Wax emulsion end sealing reduces moisture ingress. The timber is sourced from FSC-certified plantations which means that it is sustainable. LVL Scaffold planks are durable and have extremely long lifespans, they are also light and easy to handle.

Pine LVL Scaffolding Plank is used for Construction, Formwork Systems, Bridge engineering, oil field engineering, etc.

Packaging and Containerization of Australia LVL Scaffold Plank:

FAQ

Q: What is LVL?

A: LVL stands for Laminated Veneer Lumber. It is an engineered wood product made by layering thin sheets of wood veneer together with adhesive, creating a strong and durable panel.

Q: What are LVL scaffold planks?

A: LVL scaffold planks are panels made from LVL that are specifically designed for use in scaffolding applications. They are strong, slip-resistant, and compliant with the Australian Standards for Scaffolding.

Q: What sizes are available for LVL scaffold planks in Australia?

A: LVL scaffold planks are typically manufactured in sizes ranging from 225mm to 75mm wide, and up to 6 meters long.

Q: What are the benefits of using LVL scaffold planks?

A: The benefits of using LVL scaffold planks include high strength, slip-resistant surface, compliance with safety standards, environmental sustainability, versatility, and cost-effectiveness.

Q: How do LVL scaffold planks compare to other types of scaffold planks?

A: LVL scaffold planks are generally stronger and more durable than traditional scaffold planks made from solid wood. They are also more environmentally friendly than some other types of engineered wood products, such as plywood.